sequins

Member

- Joined

- Oct 14, 2014

- Messages

- 1,478

Hello friends,

My 38/357 seating die is optimized for my 357 loads and im loading 38s today, but even at maximum depth it leaves a fair bit of a 148gn DEWC outside the case.

Is this a problem to the degree that I should adjust my die zero, or do you think it's okay? The rounds look a little funny not seated flush but I don't want to adjust the zero unless it's really necessary.

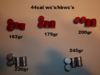

Here's a picture, these 38spls have a COAL of 1.360" and my MBC 148gn wadcutters are 0.574" long.

My 38/357 seating die is optimized for my 357 loads and im loading 38s today, but even at maximum depth it leaves a fair bit of a 148gn DEWC outside the case.

Is this a problem to the degree that I should adjust my die zero, or do you think it's okay? The rounds look a little funny not seated flush but I don't want to adjust the zero unless it's really necessary.

Here's a picture, these 38spls have a COAL of 1.360" and my MBC 148gn wadcutters are 0.574" long.