Still a newb -

looking for feedback- please -

I had 600 nickel cases of .556 range brass, 90% FC marked, 10% LC marked, all have crimped pockets, gifted to me.

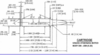

All cleaned up beautifully with my wet tumbler.

I'm trimming them down to 1.7495.with the Wilson lathe trimmer. and yes, nickle trims a little tougher than brass

75% of them all trimmed to either .7495 or .750

25% of the batch too are short for the trimmer, I guess the factory produced them short.

What could I do with the shorter stuff, they measure at .743 to .748 ?

I believe I can trim them to .743 and keep them all together and they'll be all fine, according to the "internet"

I would be putting a real small crimp to the cases, so keeping sizes segregated is the proper procedure, I assume.

I'm looking to keep these nickel cases for use in decent accuracy, not LRPrecision, I'm not advanced enough, and my pockets are not bottomless -

I use a mighty armory decapper and TNT Gold sizer, Redding competition seater, Lee FCD.

have 68-77 gr. hornady's, smk's, (maybe even try an eld bullet)

other - any consideration in cannelure bullets vs. plain

powder choices- varget, cfe223, blc2, A2230, A2520, and a few more-

figuring to start at mid loads, then work up .2 or .3 up - using Lee, Hornady manuals,and Hodgin's online for load info and coal. I have no chrono at this point -

shooting out of decent AR rifle barrels.

looking for feedback- please -

I had 600 nickel cases of .556 range brass, 90% FC marked, 10% LC marked, all have crimped pockets, gifted to me.

All cleaned up beautifully with my wet tumbler.

I'm trimming them down to 1.7495.with the Wilson lathe trimmer. and yes, nickle trims a little tougher than brass

75% of them all trimmed to either .7495 or .750

25% of the batch too are short for the trimmer, I guess the factory produced them short.

What could I do with the shorter stuff, they measure at .743 to .748 ?

I believe I can trim them to .743 and keep them all together and they'll be all fine, according to the "internet"

I would be putting a real small crimp to the cases, so keeping sizes segregated is the proper procedure, I assume.

I'm looking to keep these nickel cases for use in decent accuracy, not LRPrecision, I'm not advanced enough, and my pockets are not bottomless -

I use a mighty armory decapper and TNT Gold sizer, Redding competition seater, Lee FCD.

have 68-77 gr. hornady's, smk's, (maybe even try an eld bullet)

other - any consideration in cannelure bullets vs. plain

powder choices- varget, cfe223, blc2, A2230, A2520, and a few more-

figuring to start at mid loads, then work up .2 or .3 up - using Lee, Hornady manuals,and Hodgin's online for load info and coal. I have no chrono at this point -

shooting out of decent AR rifle barrels.