1KPerDay, just to round out this subject of extractor deflection I thought I'd post this.

Below is what a perfectly fit extractor looks like at the business end. Note that the hook does not touch the case anywhere.

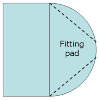

Below are three images showing what happens to the extractor as a cartidge slides up the breechface during the feeding cycle. The perspective is from the muzzle. The dashed vertical line inside the extractor represents the tensioning wall.

The first image shows the case rim before it engages the extractor. More precisely, the rim has not contacted the tensioning wall yet. Here the extractor's locating pad is in contact with the inside left of the slide tunnel (not shown).

The second image shows that when the rim contacts the tensioning wall the extractor is pushed away from the pistol's centerline.

The last image shows the case rim fully engaged with the tensioning wall. It is at this point that extractor deflection is at its maximum.

Deflection, also referred to as cam out, is very important. A minimal amount of deflection will allow good functioning with more tension than what is generally considered prudent. But an extractor with lots of deflection can cause malfunctions even if the extractor has very little tension.

So that's the theory. How do you set extractor deflection without taking all those measurements and doing the math like I posted previously? Simple. Make a guage and slide it between the left tensioning wall and the installed extractor. The tensioning wall should touch the guage. If it doesn't, remove metal from the locating pad until it does. That's it.

I make my guages from a piece of flat stock steel from MSC Direct

https://www.mscdirect.com/product/details/06104053. Here's a picture of one:

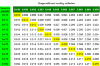

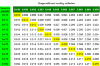

More theory. How much deflection is needed? I think Jerry Keefer said he runs somewhere around 0.006" of deflection. I try to hit 0.010". The confounding factor is case rim diameter. SAMMI spec is .480" but I don't think I've ever seen rims that wide in real life. A sampling of the brass I have on hand shows most diameters right around 0.475" or a tad bigger. Because of this I prefer my .466" guage. You can see in the table below that my .466" guage gives .010" deflection with .476" rims, a tiny bit less for .475" rims, and a tiny bit more for .477" rims.

So, if you discover that most of your rims are .480", you can use a .470" guage to achieve perfect 0.010" deflection and that should work with rims a little bit bigger and a little bit smaller. Note that if your guage is .470" and your rims are .470", the extractor will have zero deflection.

All of this talk about specifc deflection amounts is open for debate. I imagine the real 1911 'smiths here have their own preferred measurements based on their experience. All of the preceeding is based on my own experience and experimentation. Experimentation means George at EGW will be able to retire early thanks to all the extractors I've bought from him as I screwed up one after another in my quest for extractor perfection.

Here's a simple animation of the case rim sliding up the breechface and pushing the extractor to the side.