I do wonder, though-I've seen instructors advise holding the hammer when dropping the slide, in case a hammer hook or sear fails; wouldn't this essentially duplicate that?

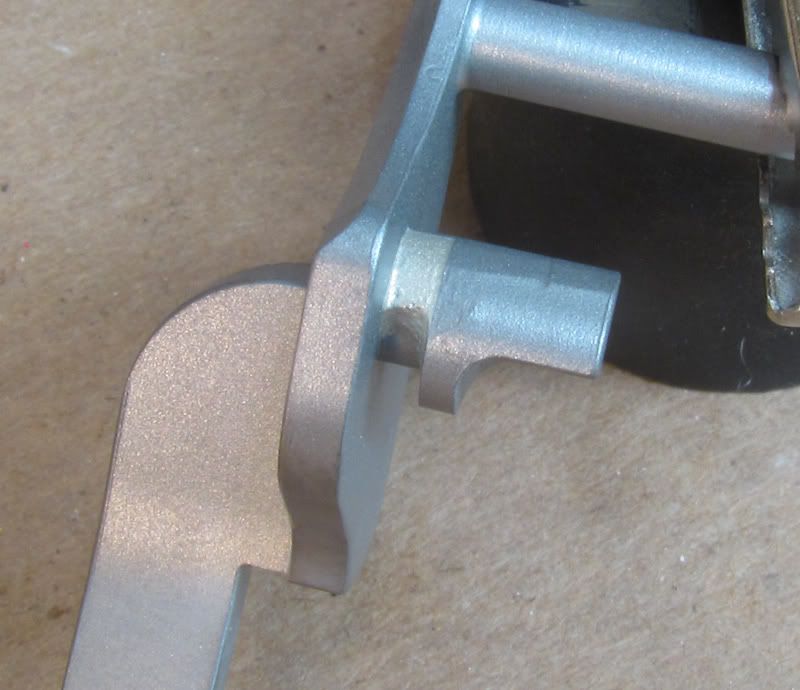

Well...Sorta, but not exactly. The thumb safety doesn't block the hammer. It blocks the sear.

Worthwhile? Not sure for what exactly. Part of owning a 1911 entails performing function and safety checks periodically unless the gun isn't fired much.

They're outlined in the Colt owner's manual...or at least they used to be.

They go as follows:

Hammer cocked. Engage thumb safety. Pull trigger. Hammer should not fall. Safety off...Hammer should fall.

Hammer cocked. Grip gun without depressing grip safety. Pull trigger. Hammer should not fall. Depressed safety...Hammer should fall.

Hammer cocked. Manually pull slide rearward approximately .100 inch. Pull trigger. Hammer should not fall. Slide full forward...Hammer should fall.

Lock slide rearward. Trip slidestop to release slide. Hammer should not fall. (If it does, get it fixed immediately.)

If it passes the last one, there's no reason to hold the hammer when releasing the slide.

To expound:

If the hammer follows the slide, most often it's stopped by the half cock or quarter cock. That followdown is most often the result of insufficient tension on the center leg of the sear spring, and most often easy to correct. The technical cause is inertial trigger bounce in which the trigger nudges the disconnect briskly enough to roll the sear out of the hooks. The sear resets and grabs the half cock notch, stopping the hammer from reaching the firing pin. Falling all the way to the firing pin suggests another, more serious issue.

In this respect, the ability to keep the gun on-safe while manually operating the slide could possibly mask a functional problem that...if left unattended...could result in a dangerous condition. So, regardless of whether you decide on this option...performing the safety function tests should still be done. The frequency depends on how much the gun is fired. Colt says before every workout, but it's not critical to do it that often. I shoot a lot...a LOT...and I do it 3-4 times a year.