I'm trying to find reloading data using Win 231 powder to load some Everglades SWC 158 grain bullets. The Everglades SWC are plated not cast. Everglades sent 500 of these to me by mistake, so I might as well use them.

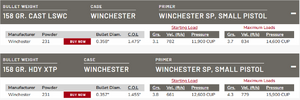

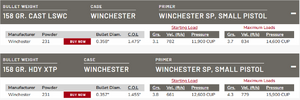

The Hodgdon Data web site doesn't give Win 231 data for plated SWC, but does for Hornady XTP and cast LSWC with different grain weights.

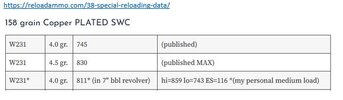

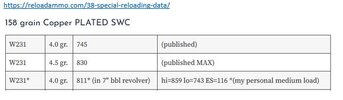

Another site, reloadammo, gives Win 231 data for plated SWC, but that data is different than the Hodgdon data.

The common denominator for all the data is the bullet weight of 158 grain and win 231 powder.

Three questions:

1. My assumption that regardless of the bullet type, if the bullet weight is the same (i.e. 158 gr) and the powder is the same (Win 231), then the amount of powder is the same. For instance 158 gr FMJ takes the same amount of Win 231 as a 158 gr hollow point, and the same for a 158 gr SWC, is wrong.

2. If my assumption is wrong, will someone explain why?

3. Is the reloadammo data for Win 231 and 158 gr plated SWC, 4.0 to max 4.5, good enough to go?

The Hodgdon Data web site doesn't give Win 231 data for plated SWC, but does for Hornady XTP and cast LSWC with different grain weights.

Another site, reloadammo, gives Win 231 data for plated SWC, but that data is different than the Hodgdon data.

The common denominator for all the data is the bullet weight of 158 grain and win 231 powder.

Three questions:

1. My assumption that regardless of the bullet type, if the bullet weight is the same (i.e. 158 gr) and the powder is the same (Win 231), then the amount of powder is the same. For instance 158 gr FMJ takes the same amount of Win 231 as a 158 gr hollow point, and the same for a 158 gr SWC, is wrong.

2. If my assumption is wrong, will someone explain why?

3. Is the reloadammo data for Win 231 and 158 gr plated SWC, 4.0 to max 4.5, good enough to go?