Crazy Horse

Member

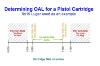

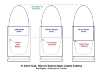

I purchased 500 9mm 147 grain RMR Match grade FN bullets. There were details in their website about using 1.130 OAL as listed in several reloading manuals.

I first tried reloading to 1.130 using 4.1 grains of CFE Pistol, but the bullets jammed in all except my Canik semi.

I went back and setup 10 rounds at 1.25, 1.20, and 1.15. Well, all of them jammed.

I looked at SAAMI specs and it lists the min OAL at 1.00 for 9mm.

I set the Min OAL to 1.10, but it still didn't pass the plunk test on my Taurus G3.

Before proceeding further, I wanted to inquire if anyone has used the RMR FN 147 match grade 9mm bullets? If so, what OAL did you utilize.

I know that plunk test indicates what will work on a firearm, but I just want to make sure before proceeding.

I still have most of those bullets, and am thinking about getting the 147 grain RN 147 gr 9mm bullets to see if those will cycle better at the 1.130 OAL as indicated in Speer #15 manual.

TIA

I first tried reloading to 1.130 using 4.1 grains of CFE Pistol, but the bullets jammed in all except my Canik semi.

I went back and setup 10 rounds at 1.25, 1.20, and 1.15. Well, all of them jammed.

I looked at SAAMI specs and it lists the min OAL at 1.00 for 9mm.

I set the Min OAL to 1.10, but it still didn't pass the plunk test on my Taurus G3.

Before proceeding further, I wanted to inquire if anyone has used the RMR FN 147 match grade 9mm bullets? If so, what OAL did you utilize.

I know that plunk test indicates what will work on a firearm, but I just want to make sure before proceeding.

I still have most of those bullets, and am thinking about getting the 147 grain RN 147 gr 9mm bullets to see if those will cycle better at the 1.130 OAL as indicated in Speer #15 manual.

TIA