You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Alternative Measure Pressure?

- Thread starter jski

- Start date

fxvr5

Member

- Joined

- May 26, 2017

- Messages

- 3,270

No. He's not measuring pressure. What he's measuring is case head expansion. Chamber pressure is measured in CUP or PSI, the latter being more accurate and the preferred method as CUP is being phased out. Pressure measurements result in pressure values, not 'it's expanded too far" or whatever.

He's doing the old fashioned way, which some companies used to do. And it's discussed in Hornady's manual, as well. They use it when they don't have test barrels for odd-ball cartridges.

His bragging is hilarious, and delusional, that you can measure pressure his way. How can he tell when he's at 45,500 psi? Or 17,235 psi? See the problem?

He's doing the old fashioned way, which some companies used to do. And it's discussed in Hornady's manual, as well. They use it when they don't have test barrels for odd-ball cartridges.

His bragging is hilarious, and delusional, that you can measure pressure his way. How can he tell when he's at 45,500 psi? Or 17,235 psi? See the problem?

My head was about to explode as I watched the video.

There was a lot of commentary, but not a lot of actual science.

fxvr5 pretty much nailed the problems with the methodology, so I don't need to recount them here.

Bottom line; follow the manuals.

There was a lot of commentary, but not a lot of actual science.

fxvr5 pretty much nailed the problems with the methodology, so I don't need to recount them here.

Bottom line; follow the manuals.

OS/N

Member

- Joined

- Nov 2, 2023

- Messages

- 246

In a time when it's difficult to find exact components for relaoding and raw materials change so frequent from suppliers, I think this is good information to have as part of a reloaders knowledge base. Not many of the components are the same today as they were when much of the loading data we use today was developed.

It probably doesn't make that much difference when loading level one 45 colt, 38spl, or 9mm but when dealing with 62kpsi rifle cases it is good info to have.

It probably doesn't make that much difference when loading level one 45 colt, 38spl, or 9mm but when dealing with 62kpsi rifle cases it is good info to have.

AJC1

Member

I don't tend to put a lot of stock in claims that are widely out of normal. The technique is used to check for overpressure, or problems but not xxx psi.

Ken Warner was a huge proponent of case head expansion. Which is probably where the "Real Gunsmith" got this idea. It works out in theory, but not in practice. Alas, Ken Warner never checked his case head expansion results against an actual pressure gauge. The foundations of his technique were a delusion.

Delusions in, delusions out.

Delusions in, delusions out.

rfwobbly

Member

One time I made the mistake of picking up brass after an action pistol match. At the next match some of my carefully crafted "Match" handloads wedged themselves solidly into the tapered chamber on my 9mm, thus ending that day's match for me. Later upon measuring these cases, it was discovered the case head had expanded just 0.002" at a position my dies couldn't reach. Those were the cases from the Open Class boys, and that's why they were left on the ground ! Lesson learned !!

So case head expansion is a real thing, but only in over-pressure scenarios. I agree with fxvr5. By the time you are expanding case heads, you are well into the Danger Zone... a place you shouldn't even be near. For the average shooter, "nothing good happens at Max Load". If you really want to know your chamber pressure, then buy a chronograph. For $100 you can get a very advanced chrono that will even send all the data to your phone.

Hope this helps.

So case head expansion is a real thing, but only in over-pressure scenarios. I agree with fxvr5. By the time you are expanding case heads, you are well into the Danger Zone... a place you shouldn't even be near. For the average shooter, "nothing good happens at Max Load". If you really want to know your chamber pressure, then buy a chronograph. For $100 you can get a very advanced chrono that will even send all the data to your phone.

Hope this helps.

mcb

Member

Measuring pressure in chambers has always been a fascination of mine. From learning how the modern piezo transducer methods work (SAAMI, NATO, CIP etc), back through crusher to even older methods that dating back to the beginning of gun powder (Black Powder). The internet is wonderful for that, being able to find and read internal ballistics papers and book that were published, some going back to before 1900. The old ones are almost always free having entered the public domain. Also https://discover.dtic.mil/ is a wonderful source of declassified technical papers (more than just ballistics but a lot of that too). The big bore stuff you can put pressures sensors (and other sensors) on the rounds themselves in addition to multiple location along the barrel.

I have always been tempted to put a strain gauge on one of my rifles to measure pressure that way but I change rifles too often to really get enough use out of it to justify the ugly strain gauge install. Back when I was playing serious with 410 slugs (lived in a slug only deer hunting state) I did play around with using pressure sensitive film intended for the mold and die making industries to measure the pressure of my loads. Started with very carefully loaded ammunition using published data and that correlated well with the pressure film measurements. I then used that measurement system and an old internal ballistic software called NABM to work up some pretty potent 410 slug loads. It worked very well but was limited to shotgun pressure and taking advantage of the loose fit a shotgun shell make with its chamber. It would not have worked with metallic cartridges.

I have always been tempted to put a strain gauge on one of my rifles to measure pressure that way but I change rifles too often to really get enough use out of it to justify the ugly strain gauge install. Back when I was playing serious with 410 slugs (lived in a slug only deer hunting state) I did play around with using pressure sensitive film intended for the mold and die making industries to measure the pressure of my loads. Started with very carefully loaded ammunition using published data and that correlated well with the pressure film measurements. I then used that measurement system and an old internal ballistic software called NABM to work up some pretty potent 410 slug loads. It worked very well but was limited to shotgun pressure and taking advantage of the loose fit a shotgun shell make with its chamber. It would not have worked with metallic cartridges.

denton

Member

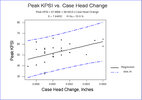

Measuring case head expansion is an extremely poor way to estimate pressure. I did take the time to compare it with a proper measurement system, and the results are shown in the attached file. Anybody who thinks they can measure or even reasonably estimate chamber pressure from measurements of case head expansion of a few cartridges is dreaming.

You'll need to download the file to read the whole thing, but the bottom line is that CHE does contain a little bit of information, but is mostly random statistical noise. I have a table of random numbers you can borrow that will give you almost as good an answer as CHE, and using that will save you the bother of having to make measurements.

You'll need to download the file to read the whole thing, but the bottom line is that CHE does contain a little bit of information, but is mostly random statistical noise. I have a table of random numbers you can borrow that will give you almost as good an answer as CHE, and using that will save you the bother of having to make measurements.

Attachments

Last edited:

jmorris

Member

- Joined

- Sep 30, 2005

- Messages

- 24,184

Later upon measuring these cases, it was discovered the case head had expanded just 0.002" at a position my dies couldn't reach. Those were the cases from the Open Class boys, and that's why they were left on the ground ! Lesson learned !!

I don’t know, I run 9mm at 175PF and don’t have problems. Sounds like you got one fired from an SMG, ours always leave the base big, even with my “minor“ loads I run in most of my 9mm’s.

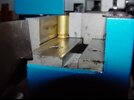

There are machines that can correct it though, push through sizers are one way and there are roll sizers too. I have a couple case pro machines myself, automated this one.

The even iron out dings in the rim/extractor groove.

.308 Norma

Member

Maybe I don't understand what the "recoil plate" is, but I'm sure the case in a revolver slams up against something. That action is what pushes the primer back into its pocket. And if there wasn't enough pressure to make the case "slam" hard enough against whatever it slams against, the primer would be left sticking out - which will lock the revolver up in short order.In a wheelgun, the case does not slam up against the recoil plate.

I've had a couple of experiences with revolvers locking up due to extended primers, and in both cases (no pun intended) the primers didn't reseat because my loads were too light. As a matter of fact, the "loads" that locked up one of my revolvers didn't have any powder OR bullets - I was conducting an experiment to find out if oil will reliably de-activate primers. BTW, it won't.

I call it the breech face, and yes, all guns have something the case stops against. Not sure why that's relevant to case head expansion.Maybe I don't understand what the "recoil plate" is, but I'm sure the case in a revolver slams up against something.

OK sorta good reading. Reloader feel, Wildcat reloader feel. Is like mechanics feel. You know when your there but trying to explain it or teach it isn't happening. Begins with experience and situational awareness. Being aware of pressure is learned.

The recoil plate/shield is the part of the frame just behind the cylinder. The lateral expansion of the case against the chamber wall prevents the case from flying backward.Maybe I don't understand what the "recoil plate" is, but I'm sure the case in a revolver slams up against something. That action is what pushes the primer back into its pocket. And if there wasn't enough pressure to make the case "slam" hard enough against whatever it slams against, the primer would be left sticking out - which will lock the revolver up in short order.

I've had a couple of experiences with revolvers locking up due to extended primers, and in both cases (no pun intended) the primers didn't reseat because my loads were too light. As a matter of fact, the "loads" that locked up one of my revolvers didn't have any powder OR bullets - I was conducting an experiment to find out if oil will reliably de-activate primers. BTW, it won't.

.308 Norma

Member

No sir, it does not.The lateral expansion of the case against the chamber wall prevents the case from flying backward.

No sir, it does not.

Correct, the softer part of the case expands and seals in the hot high pressure gases, while the breech face stops the case head from moving too far back and coming off.

Read up on headspace and head clearance.

Woe, woe, woe, are you saying that every time you fire a round in a revolver, the case slams up against the recoil plate/shield? That the lateral pressure against the chamber wall prevents nothing? I want to be very clear here.

Yes, the front part of the case which is softer (on purpose) than the case head expands and seals the chamber. The case then stretches until the breech face stops it, which is why mechanical headspace and actual head clearance is so important. An excess of either leads to case head separation. Read the thread I linked to in my post.

Yep, the primer is pushed out by pressure, then reseated by the breech face.That action is what pushes the primer back into its pocket. And if there wasn't enough pressure to make the case "slam" hard enough against whatever it slams against, the primer would be left sticking out - which will lock the revolver up in short order.

Are there videos of this?Yep, the primer is pushed out by pressure, then reseated by the breech face.

Similar threads

- Replies

- 8

- Views

- 600

- Replies

- 3

- Views

- 2K

- Replies

- 3

- Views

- 1K