expat_alaska

Member

My take, if you will oblige.

I have shot a Longslide (Irwindale) that belonged to a friend in the 90's that performed very well. All factory, no gunsmith work. It was a bit muzzle-heavy, but that is never a problem for me.

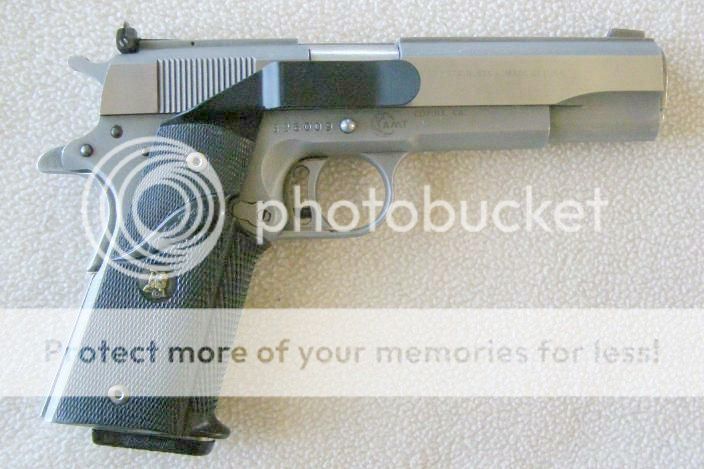

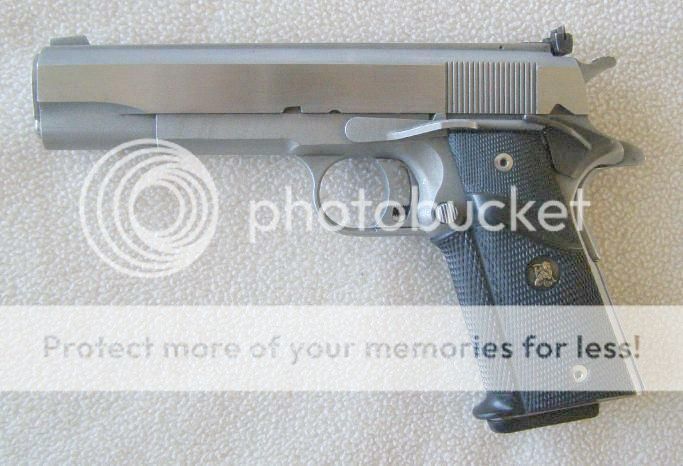

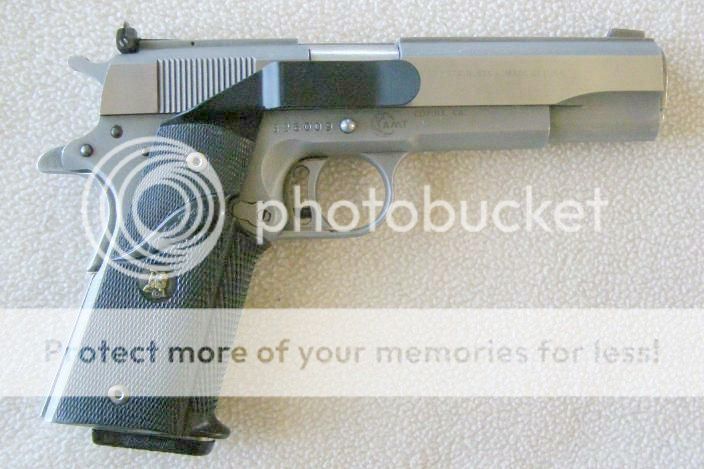

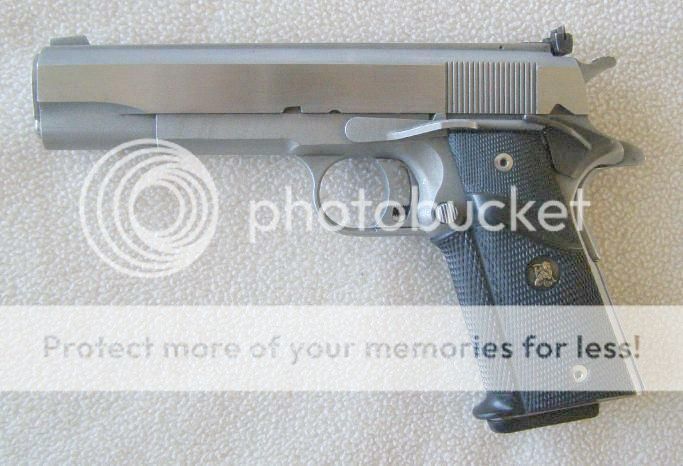

I also own an AMT Hardballer 5" (Covina) that I bought outside of a gun show in 1992, with 2 factory stainless mags for $150.

When I got it home, the perfunctory safety checks were made: cocked and locked, upon pressing the trigger, both the thumb safety AND the hammer dropped. After disassembly, I found that the sear pin was bent. (Covina AMT's were notorious for soft stainless; not so much with the Arcadia pistols, and the Irwindales were even better).

I replaced the extractor, sear pin, hammer pin, thumb safety, and hammer strut with blued carbon steel parts, and throated the barrel. It will chamber and fire just about any .45 ACP HP loads, including long ago handloads using the infamous Speer 200 gr JHP "flying ashtray". As has been mentioned previously by others, it does like to be run wet. It has been my HD/SD/Truck gun since then. It ain't pretty, but it always runs.

Pay no attention to the ClipDraw device. I am 64, wear suspenders and no belt, don't want a holster, and live in the boontoolies. It works well for carrying around the house or the farm, and I don't seem to go much farther than that.

I have shot a Longslide (Irwindale) that belonged to a friend in the 90's that performed very well. All factory, no gunsmith work. It was a bit muzzle-heavy, but that is never a problem for me.

I also own an AMT Hardballer 5" (Covina) that I bought outside of a gun show in 1992, with 2 factory stainless mags for $150.

When I got it home, the perfunctory safety checks were made: cocked and locked, upon pressing the trigger, both the thumb safety AND the hammer dropped. After disassembly, I found that the sear pin was bent. (Covina AMT's were notorious for soft stainless; not so much with the Arcadia pistols, and the Irwindales were even better).

I replaced the extractor, sear pin, hammer pin, thumb safety, and hammer strut with blued carbon steel parts, and throated the barrel. It will chamber and fire just about any .45 ACP HP loads, including long ago handloads using the infamous Speer 200 gr JHP "flying ashtray". As has been mentioned previously by others, it does like to be run wet. It has been my HD/SD/Truck gun since then. It ain't pretty, but it always runs.

Pay no attention to the ClipDraw device. I am 64, wear suspenders and no belt, don't want a holster, and live in the boontoolies. It works well for carrying around the house or the farm, and I don't seem to go much farther than that.