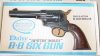

Some good some bad, got the new lever in, no BBs out yet. It had a catastrophic failure of the lever the hammer hits on, then I'd say the kid smashed the gun down and broke the lever, sort of like when I used to break golf clubs. But I can tell it's got some power just by cocking it. I'd say on par with my modded RR.

I want to thank KR in Ohio for the manual, he even sent three targets along with. It's much easier to read than the down loaded copy I found. Also Denis in WI who sent the new/used lever off fleabay, it was in good shape and works well. As a bonus it's the new style where the two halves are welded on the short arm thingy?

When I called one fellow about a parts list he said they don't use one. The parts are hard to match up and hard to work on, I should send it in for repair. It is a bit fiddly, but went step by step with the manual and took pics. There is a couple vids on the tube also.

All I started out to do was replace the lever, but when opened up it needed cleaning. I didn't take the power plant out though.

I read about the fellow who designed this riffle, I am impressed how well every thing fits together, it is a true copy. Even the plastic wood grain stock and forearm look good. Although my stock has a slight leftward warp, the plastic is very sturdy, unlike todays cheap junk.

I'm leaving it cocked over night, to see if the seal might reform and push a little air out the barrel. If not tomorrow I'll get some of that transmission stop leak and give it a bath, for a temporary fix. That stuff is supposed to make seals swell up. The barrel was dirty but not rusty so I think the air chamber will be OK, hope the air tube isn't split.

Thanks Cobalt for the links

This thing is no rapid fire blazing saddles gun, when you cock it forward you have to put the safety on to return the lever, then cock the hammer again to shoot.

When I opened it up I could see there was a problem with a bent arm- top arrow in pic.

to be continued.....