Back when I was getting started in knives, AUS-8 was pretty much considered to be a premium knife steel. I still have some knives with AUS-8 blades, and even one with the Chinese equivalent, 8Cr13MoV or 8Cr14MoV.

I've wondered how it stacked up compared to some of the new "supersteels". Dr. Thomas has now answered that question with an article and a video.

Turns out it's still a decent choice--but I don't want to provide too many spoilers.

knifesteelnerds.com

knifesteelnerds.com

I've wondered how it stacked up compared to some of the new "supersteels". Dr. Thomas has now answered that question with an article and a video.

Turns out it's still a decent choice--but I don't want to provide too many spoilers.

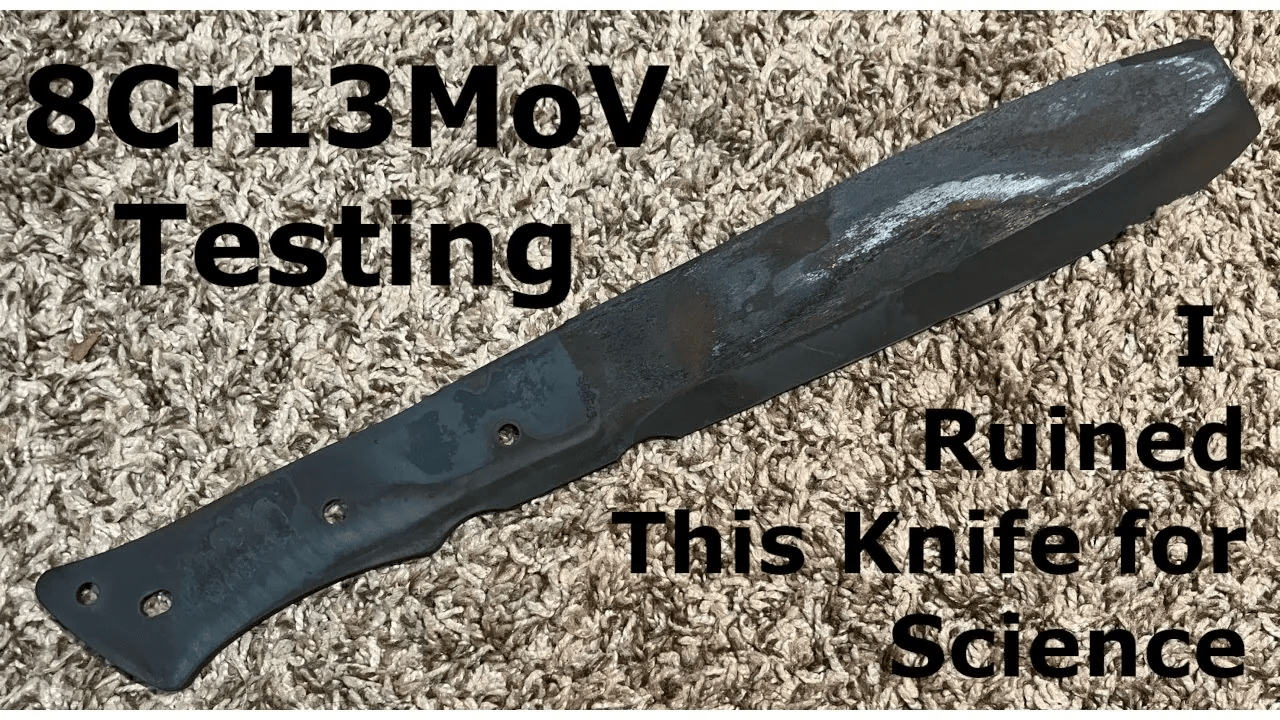

Testing Chinese Knife Steel 8Cr13MoV/8Cr14MoV - Knife Steel Nerds

New tests of Chinese knife steel 8Cr13MoV, also called 8Cr14MoV. How does it stack up against USA and European steels?