GW Staar

Member

- Joined

- Feb 26, 2009

- Messages

- 3,696

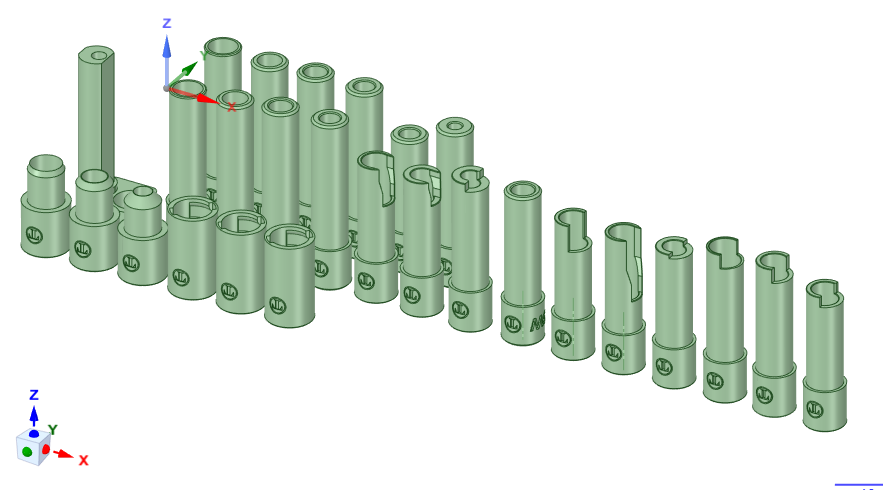

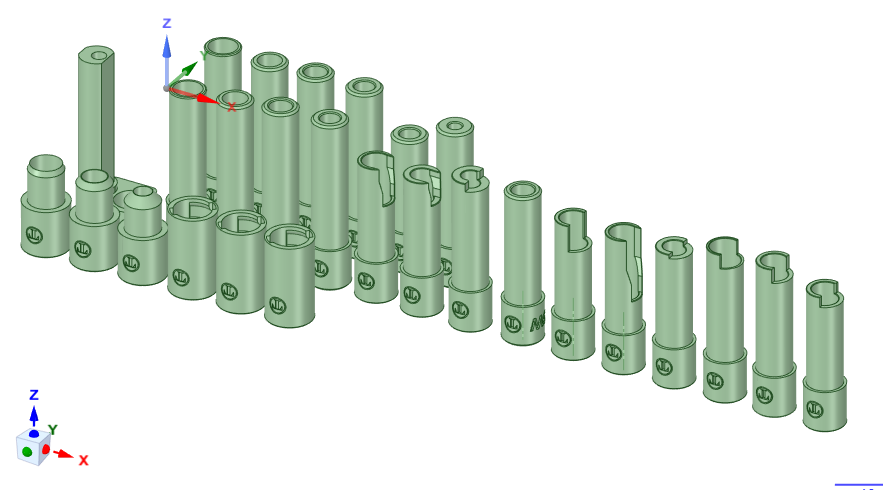

3D printed parts I used to connect my 3D printed case collator to the Lee Pro 6000.

Picture Below: The black part uses Lee's bolt and wingnut inside to mount everything to the press. It is the Caliber insert holder. Caliber insert holders, like the red 9mm version shown, is dropped in through the top of the holder. Inserts are just dropped in and turned so that the index key drops into the slot for it in the holder.....so it's pointed correctly.

The bottom of the insert is cutout on the slide facing the shell plate according to caliber. It's length allows Lee's shuttle to pass underneath....go beyond it.....wait for the case to drop to the shuttle track....then return to the shell plate with the case.

Next picture shows a closeup of the top of the of the insert. It's has a 9/16" diameter hole for Lee's 9/16" O.D clear tubing, but I cut just a short piece because I wanted to use 1/2" O.D. tubing for the small 9mm bullets. So then I inserted 1/2" tubing inside the 9/16" tubing as shown.

So below is the 1/2" tubing about 5" long.

Next, I want it mounted sturdily to the press and that's done with the 3D printed coupler below. It has a length of 9/16 tubing into the hole at the top, and a short length over the bottom of the printed part. I wanted the tubing surrounding the solid plug at the bottom because it is slicker than the PLA plastic of the printed part and so slides in and out of the press more easily even as tight as it has to be, so there's minimum flex.....and repeated in and outs are down without wear. Works well.

Below.....it drops into the hole in the front of the Lee casting.

Next, I mounted my proximity case sensor to a twist lock fitting then to 5/8" thin wall plastic tubing, so it just drops over the top and tubing inside slides freely insides it up and down with each stroke.

The next picture is just to show an important feature. When you use telescoping tubing like this, the only way not to have cases catch an edge and stop falling, is to bevel the top edges of the tubing. In this case the 9/16" and the 1/2" O.S. diameter tubing. I bevel it using my RCBS Trim Mate with the case edge beveling tool. Makes case drop without the lease bit of friction.

Finally two short videos......the first shows how moving Lee case shuttle can work with a stationary Electric Collator.

The next video is the one I already showed in a couple of other threads, showing how it all works........

Two little hiccups were caused by cases that had problems with their base surfaces......making them not so easy to slide......so examine your cases before you reload them...wasn't the press's fault.

So what about other calibers....even rifle? Change caliber insert, change tubing, and change collator plate.

The TylerR system makes it easy. Most any caliber.........bullets, or cases.

Picture Below: The black part uses Lee's bolt and wingnut inside to mount everything to the press. It is the Caliber insert holder. Caliber insert holders, like the red 9mm version shown, is dropped in through the top of the holder. Inserts are just dropped in and turned so that the index key drops into the slot for it in the holder.....so it's pointed correctly.

The bottom of the insert is cutout on the slide facing the shell plate according to caliber. It's length allows Lee's shuttle to pass underneath....go beyond it.....wait for the case to drop to the shuttle track....then return to the shell plate with the case.

Next picture shows a closeup of the top of the of the insert. It's has a 9/16" diameter hole for Lee's 9/16" O.D clear tubing, but I cut just a short piece because I wanted to use 1/2" O.D. tubing for the small 9mm bullets. So then I inserted 1/2" tubing inside the 9/16" tubing as shown.

So below is the 1/2" tubing about 5" long.

Next, I want it mounted sturdily to the press and that's done with the 3D printed coupler below. It has a length of 9/16 tubing into the hole at the top, and a short length over the bottom of the printed part. I wanted the tubing surrounding the solid plug at the bottom because it is slicker than the PLA plastic of the printed part and so slides in and out of the press more easily even as tight as it has to be, so there's minimum flex.....and repeated in and outs are down without wear. Works well.

Below.....it drops into the hole in the front of the Lee casting.

Next, I mounted my proximity case sensor to a twist lock fitting then to 5/8" thin wall plastic tubing, so it just drops over the top and tubing inside slides freely insides it up and down with each stroke.

The next picture is just to show an important feature. When you use telescoping tubing like this, the only way not to have cases catch an edge and stop falling, is to bevel the top edges of the tubing. In this case the 9/16" and the 1/2" O.S. diameter tubing. I bevel it using my RCBS Trim Mate with the case edge beveling tool. Makes case drop without the lease bit of friction.

Finally two short videos......the first shows how moving Lee case shuttle can work with a stationary Electric Collator.

The next video is the one I already showed in a couple of other threads, showing how it all works........

Two little hiccups were caused by cases that had problems with their base surfaces......making them not so easy to slide......so examine your cases before you reload them...wasn't the press's fault.

So what about other calibers....even rifle? Change caliber insert, change tubing, and change collator plate.

The TylerR system makes it easy. Most any caliber.........bullets, or cases.

Last edited: