The Universal Case Dropper for Lee is now sold out. Hopefully he will produce more.

www.etsy.com

www.etsy.com

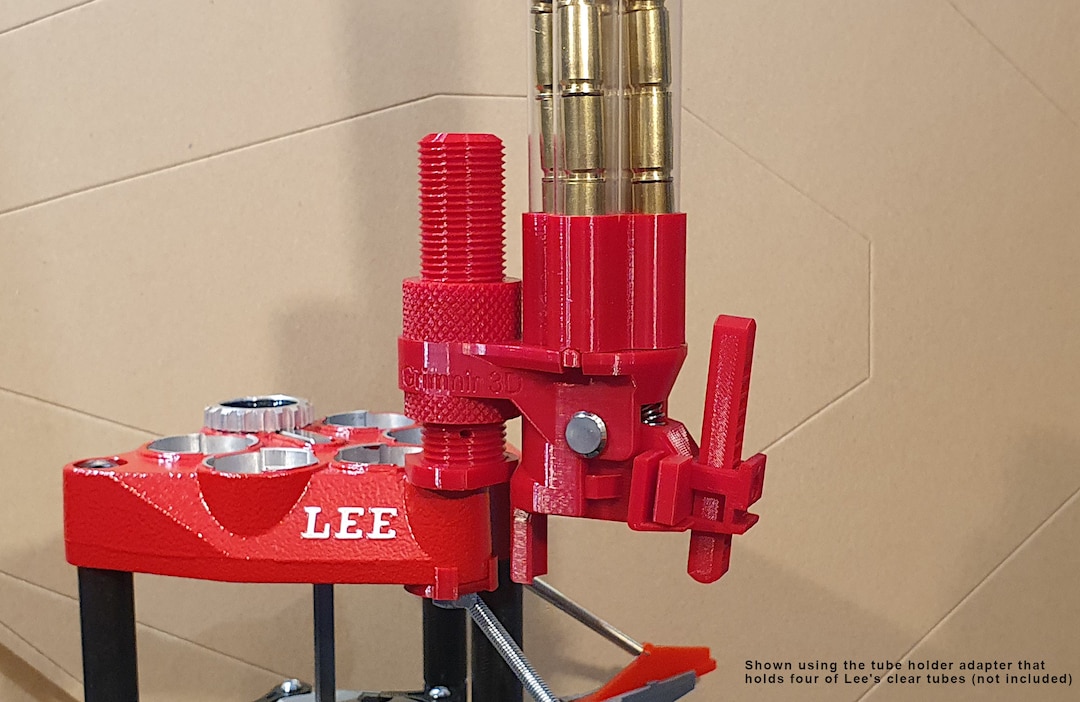

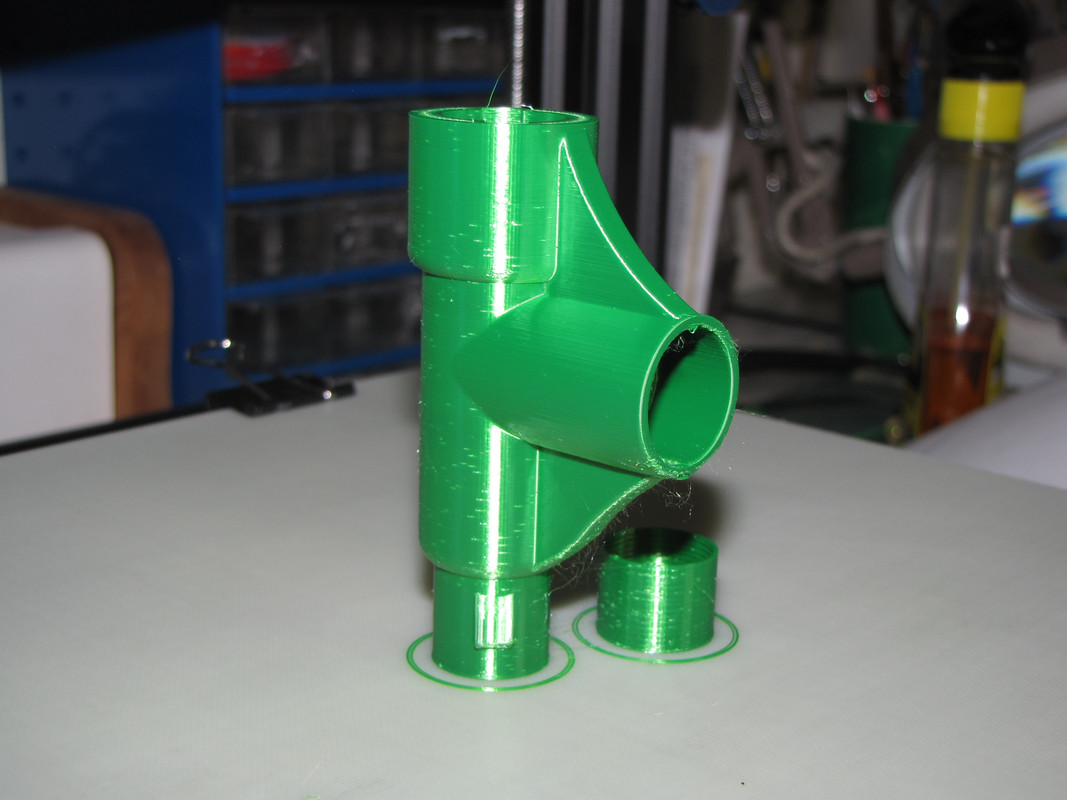

Universal Case Dropper for Lee Six Pack Pro 6000 Silver Color - Etsy

This Hunting item by Grimnir3D has 21 favorites from Etsy shoppers. Ships from Norway. Listed on Apr 2, 2024