RealGun

Member

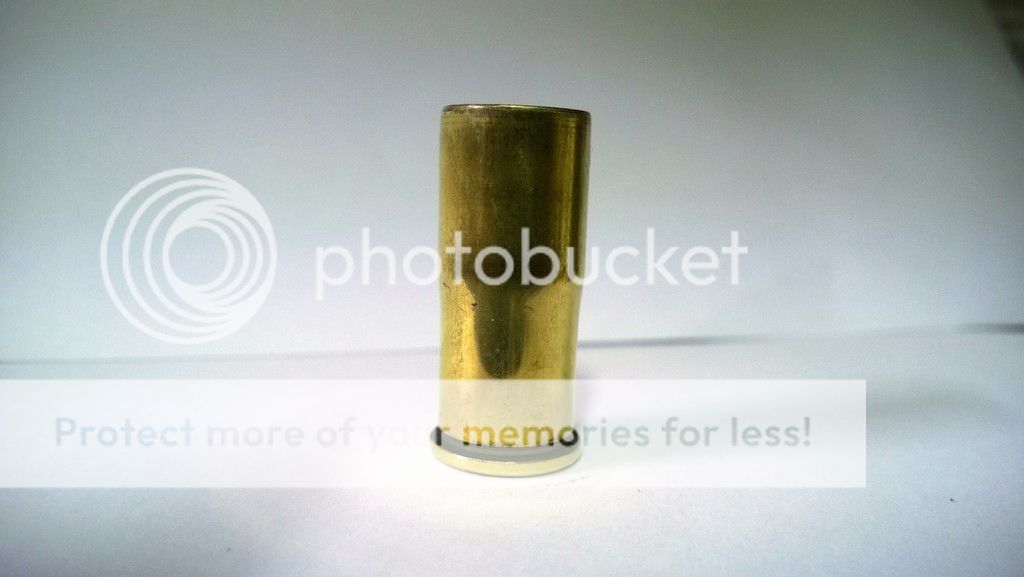

what a 44 Special would do in a 45 Colt. Oops!

This was fired accidentally in a 45 Blackhawk.

This was fired accidentally in a 45 Blackhawk.

I think it tells us where the pressure was enough to fire form the case to the larger chamber.So what's the story on why the bulge only goes halfway down?

I think it tells us where the pressure was enough to fire form the case to the larger chamber.

So what's the story on why the bulge only goes halfway down?

Damn, that's interesting! I understand that it was fire formed to the larger chamber but why only halfway? Did the pressure subside halfway?

That's a fact. This actually happened because I carry a box of jacketed reloads for a couple rounds to chase lead at the end of a shooting session. There are two rows of each cartridge, one box for large and one for small, sub .400. I just picked from the wrong row of the big bore box, and the 44 Mag was two more rows down. I try to keep a shorter cartridge in between the longer ones, but I don't know what happened for sure. In any case, this was a 45 Blackhawk, so how bad could it have been? The chaser rounds are all mild reloads.While the mess up of shooting the .44 Special in a 45 Colt is not good it could have been worse. It could have been a full power .44 Magnum.

I am skeptical about the transition to stronger brass being so abrupt. What I do get is the notion of peak pressure moving forward.I suppose that's necessarily true, but then the question becomes: is that because the pressure was higher above the line, or because the brass below the ring was stronger?

Pressure doesn't move forward. Gasses exert pressure in all directions, so regardless of when the pressure peak occurs, it is the same throughout the barrel, from the head of the case to the base of the bullet.I am skeptical about the transition to stronger brass being so abrupt. What I do get is the notion of peak pressure moving forward.

I like ATLDave's theory.Pressure doesn't move forward. Gasses exert pressure in all directions, so regardless of when the pressure peak occurs, it is the same throughout the barrel, from the head of the case to the base of the bullet.

"I thought it would have been very obvious"... that the expansion was too abrupt to attribute the resulting shape entirely to the case thickness taper.I thought it would've been very obvious that the web at the case head was the reason for the way the case expanded.

I think the notion of "ironing lead into the bore" is ridiculous. The extent of hand wringing on gun forums has no bounds. I use mild chaser rounds (jacketed) on the advice of my gunsmith and well known custom gun maker, who also strongly advises against cleaning the bore of an actively used gun...ever, inserting nothing into the barrel, not even a cotton patch, over concern for dulling the rifling and prematurely "wearing out" the barrel, cleaning it to death. It's fine. We don't cut paper with our best barber shears, and this is no different. It's a sharp edge.I have seen this happen too many times at several ranges and the cause was always people laying out all their gear on the line and mixing up ammo from multiple open boxes. All you have to do is adopt the rule - one gun - one box of ammo. When you are done shooting that gun, put it AND the ammo away. It's just too easy to make a mistake when you get in a hurry or when someone else who is inexperienced is loading guns with no supervision. One gun - one box of ammo. Also - shooting a jacketed round to get lead out of the barrel merely irons it onto the bore real good to where a Lewis lead remover can't even get it all off. If the lead is heavy enough pressures will spike when the jacketed rounds tries to push through it. It is a very common but very bad habit. Shoot your jacketed rounds first and then shoot your lead loads and then take it home and clean the lead out with a lead removal tool like the Lewis or a copper Chore Boy patch wrapped around an old brush. Don't try to shoot it out.

I think the notion of "ironing lead into the bore" is ridiculous. The extent of hand wringing on gun forums has no bounds. I use mild chaser rounds (jacketed) on the advice of my gunsmith and well known custom gun maker, who also strongly advises against cleaning the bore of an actively used gun...ever, inserting nothing into the barrel, not even a cotton patch, over concern for dulling the rifling and prematurely "wearing out" the barrel, cleaning it to death. It's fine. We don't cut paper with our best barber shears, and this is no different. It's a sharp edge.

.

I don't buy that. I've routinely cleaned my guns after each range session.

<snip>

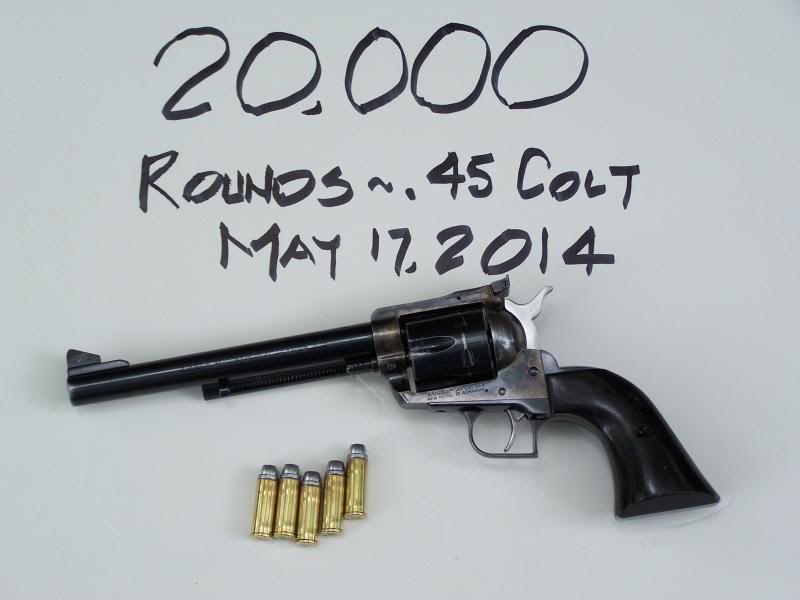

I have used stainless steel bore brushes ever since they became available, using Hoppe's No. 9 solvent and flannel cleaning patches. There is no evidence of loss of accuracy, and this gun dates back to 1987 or so, and as shown just passed the 20,000 round mileage marker.

The rifling does not need a sharp corner, as evidenced by Marlin's Micro-Groove rifling, and hexagonal bores on some guns. The oversized bullet will swage up to fit the rifling. And I've never detected any skidding of my bullets.

Bob Wright