Mustanger,

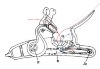

Investarms touch hole liners are very often a couple of threads too long. Unscrew your touch hole liner and look down the bore as you slowly screw the liner back in. You will probably see the liner start to protrude into the breach before it is flush with the outside of the barrel.

It is easy to file a thread or two off, whatever amount is required, to make the liner the right length.

Also some of the liners are not bored deep enough and the hole you see from the outside, the small one, is quite long before it gets to the counter bore on the inside of the liner. I use a drill bit from the inside of the liner, slightly smaller than the factory counterbore and deepen the hole so the powder is much closer to the outside touch hole leaving about a 3/32" web. I never drill the touch hole itself bigger.

Hope this makes sense. I cannot detect much, if any, delay with my rifles.

Investarms touch hole liners are very often a couple of threads too long. Unscrew your touch hole liner and look down the bore as you slowly screw the liner back in. You will probably see the liner start to protrude into the breach before it is flush with the outside of the barrel.

It is easy to file a thread or two off, whatever amount is required, to make the liner the right length.

Also some of the liners are not bored deep enough and the hole you see from the outside, the small one, is quite long before it gets to the counter bore on the inside of the liner. I use a drill bit from the inside of the liner, slightly smaller than the factory counterbore and deepen the hole so the powder is much closer to the outside touch hole leaving about a 3/32" web. I never drill the touch hole itself bigger.

Hope this makes sense. I cannot detect much, if any, delay with my rifles.