JimGnitecki

Member

- Joined

- Mar 28, 2010

- Messages

- 1,258

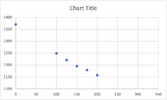

Ok, so I finally have a good 500g 45-70 bullet mold that can produce way better 5-shot groups than the 2 earlier molds I tried! I am shooting groups at 150 meters = 164 yards, where 1 MOA = 1.72 inches, and my better groups are that small or smaller, which is good when shooting a home-cast 500g wheelweight bullet out of a Pedseroli Sharps replica, at a muzzle velocity of almost 1400 fps and no leading thanks to powder coating.

But, although some groups are great, like this one (which is in fact 1 MOA at this distance):

A number of others look like this:

or like this:

There are 3 possible causes:

- Shooter error (in sighting or hold or position)

- Load quality issue

- Cast bullet quality issue

I can see already that shooter error is an obvious contributor, since the POSITION of the groups is not consistent relative to the bullseye. So, I know I need to work on consistency of my sighting, my hold, or my position.

Notice that in all 3 of these targets, the 3 best of 5 shots are all within a group size of an inch or less (i.e. 0.58 MOA at this distance).

But in targets no. 4 and 5, 3 shots are very close together, but 2 are WAY outside of those 3.

Notice also that in Target 4, the 2 wayward shots have mostly HORIZONTAL error, while in Target 5, the 2 wayward shots have mostly VERTICAL error. Does that provide any clues as to what is going wrong with those shots?

I have not yet had time to analyze the Labradar results for this range session that was fired just this afternoon. But I plan to do that analysis later this evening, to see what SD and what ES I am getting with this batch of cartridges.

In the meantime, anyone out there experienced enough to provide some diagnostic advice?

Jim G

But, although some groups are great, like this one (which is in fact 1 MOA at this distance):

A number of others look like this:

or like this:

There are 3 possible causes:

- Shooter error (in sighting or hold or position)

- Load quality issue

- Cast bullet quality issue

I can see already that shooter error is an obvious contributor, since the POSITION of the groups is not consistent relative to the bullseye. So, I know I need to work on consistency of my sighting, my hold, or my position.

Notice that in all 3 of these targets, the 3 best of 5 shots are all within a group size of an inch or less (i.e. 0.58 MOA at this distance).

But in targets no. 4 and 5, 3 shots are very close together, but 2 are WAY outside of those 3.

Notice also that in Target 4, the 2 wayward shots have mostly HORIZONTAL error, while in Target 5, the 2 wayward shots have mostly VERTICAL error. Does that provide any clues as to what is going wrong with those shots?

I have not yet had time to analyze the Labradar results for this range session that was fired just this afternoon. But I plan to do that analysis later this evening, to see what SD and what ES I am getting with this batch of cartridges.

In the meantime, anyone out there experienced enough to provide some diagnostic advice?

Jim G

Attachments

Last edited: