That isn't news, I've seen the same issue with the LNL Case Feeder. It is a little worst with the Dillon because the collator is so effective feeding cases into the chuteIs this the class of the field?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hornady LNL Case Feeder

- Thread starter Reeferman

- Start date

- Status

-

Not open for further replies.

SC_Dave

Member

Well I ordered it and should see it on Monday or Tuesday.

Good deal bud.

I have that issue on the LnL as well, but pretty much only with 9mm as every now and then you get one sideways and then everything just melts down, lol. Ive seen various fixes for it, but I just havent put any of them into place.Is this the class of the field?

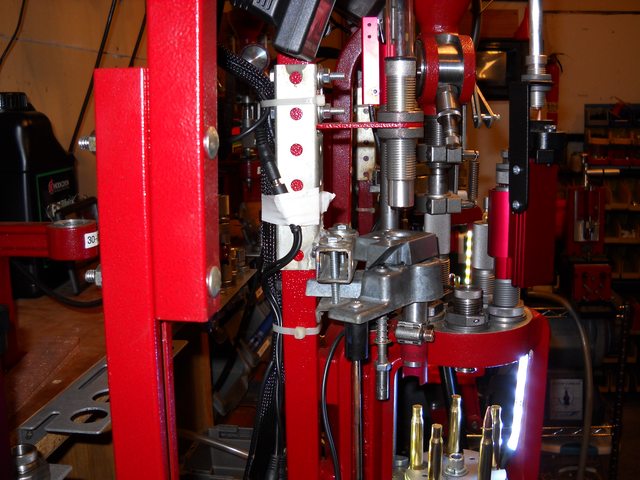

Heres a couple things Ive done.

12g shell on the drop tube. Pretty self explanatory.

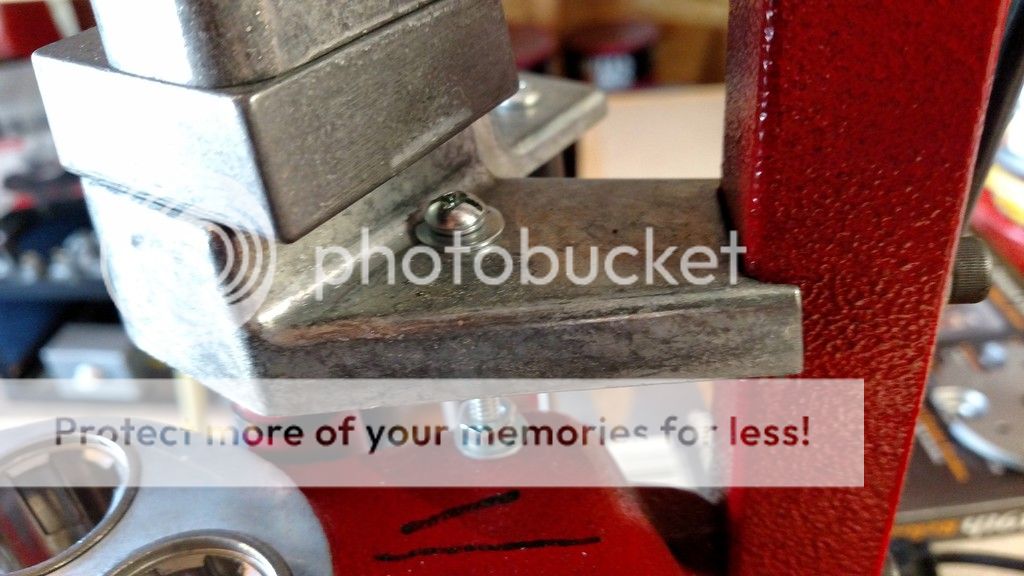

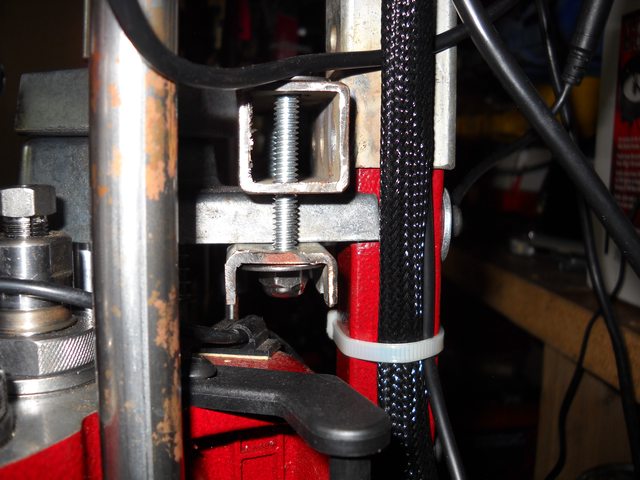

Screw thru the top the feeder bracket into the top of the press. I was getting way too much flex and twist in mine for some reason and the flipper wouldnt actuate all the way.

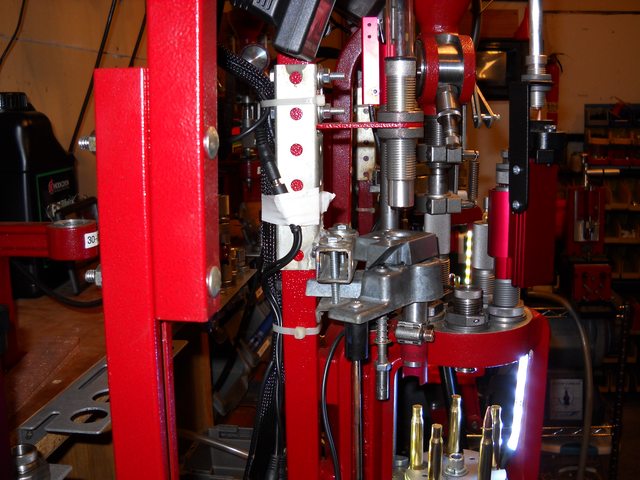

And this is the one that killed me for the longest time. I was getting a ton of galling on the flipper which was causing it to hang, and absolutely nothing I tried was solving the issue including new parts from Hornady. For this I took a piece of Delrin and a stud, and completely redid the way it works. Now it never jams up and has worked pretty well for the last 12k rounds.

12g shell on the drop tube. Pretty self explanatory.

Screw thru the top the feeder bracket into the top of the press. I was getting way too much flex and twist in mine for some reason and the flipper wouldnt actuate all the way.

And this is the one that killed me for the longest time. I was getting a ton of galling on the flipper which was causing it to hang, and absolutely nothing I tried was solving the issue including new parts from Hornady. For this I took a piece of Delrin and a stud, and completely redid the way it works. Now it never jams up and has worked pretty well for the last 12k rounds.

That looks really clever...plus it makes disassembly, and spring retention/installation, during caliber changes much easier.I was getting a ton of galling on the flipper which was causing it to hang, and absolutely nothing I tried was solving the issue including new parts from Hornady. For this I took a piece of Delrin and a stud, and completely redid the way it works.

I'm not that handy. I polished, to 600 grit, the two mating surfaces and it seems to have worked for the last few thousand rounds (9mm, .40, and .38Spl)

Had the same problem with mine.I was getting way too much flex and twist in mine for some reason and the flipper wouldnt actuate all the way.

Traced it to the Push Rod (24) being set too high. The additional traction on the inclined surface of the Pivot (19), when the metal of the Push Rod contacts the Pivot, is what causes the tilting. If you lower the Push Rod until only the Push Rod Tip (25) contacts the Pivot, the tilting/flexing/twisting goes away

That looks really clever...plus it makes disassembly, and spring retention/installation, during caliber changes much easier.

I'm not that handy. I polished, to 600 grit, the two mating surfaces and it seems to have worked for the last few thousand rounds (9mm, .40, and .38Spl)

Had the same problem with mine.

Traced it to the Push Rod (24) being set too high. The additional traction on the inclined surface of the Pivot (19), when the metal of the Push Rod contacts the Pivot, is what causes the tilting. If you lower the Push Rod until only the Push Rod Tip (25) contacts the Pivot, the tilting/flexing/twisting goes away

I tried polishing mine, went all the way to 1000 grit polishing on a glass plate followed by red rouge and a Dremel. The cheese grade pot metal just wasnt holding up. And you are absolutely correct, makes taking it apart much easier. That stupid little coil spring on that shoulder bolt is an annoyance at best and causes things to bind. You could remove that and use a spring like I did on my block to do the return. It does work, as it was one of my potential solutions I tried to make the flipper cycle smoothly. You can then remove the coil spring and just use the shoulder bolt to hold the flipper on.

I also verified my pusher was at the right height but still had some twisting issues. But this was an attempt to fix before I went to the delrin block. It moves so easily now I could probably remove the screw and it would be fine. But if it helps in any way? I just leave it in there.

I think the one issue I have is that I use this press to process range 9mm which can have all kind of dirt and crap in it which did the flipper no favors either. The delrin doesnt care if it gets scratched. I always make an effort to screen the brass several times, but you always have residual dirt on the cases.

I am going to make another block, as I have some ideas for a few improvements. The pic you are seeing is something I hacked together in about 30 minutes with my table saw, drill press and my Dremel and is not dimensionaly correct even though it does work.

I clean my cases before I start processing themI think the one issue I have is that I use this press to process range 9mm which can have all kind of dirt and crap in it which did the flipper no favors either. The delrin doesnt care if it gets scratched. I always make an effort to screen the brass several times, but you always have residual dirt on the cases.

The longer I look at the block the cooler, and more clever, it looks.I am going to make another block, as I have some ideas for a few improvements. The pic you are seeing is something I hacked together in about 30 minutes with my table saw, drill press and my Dremel and is not dimensionaly correct even though it does work.

I clean my cases before I start processing them

The longer I look at the block the cooler, and more clever, it looks.

I wet tumble, so I decap all pistol brass before it hits the tumbler. It probably wouldnt be so much of an issue if I rinsed the brass with soapy water but I dont feel like waiting for the primers to dry out before I decap. I tried that once, and said screw this, hahaha.

I should draw a 3d file in SketchUp for people to look at. I also have a buddy that does CNC machining, and I thought about having him make me one, but he just doesnt have the time.

I wet tumble also, but I don't deprime first. Since I'm not using the pins and primer pockets aren't a major issue for me, I don't need the flow through the casesI wet tumble, so I decap all pistol brass before it hits the tumbler. It probably wouldnt be so much of an issue if I rinsed the brass with soapy water but I dont feel like waiting for the primers to dry out before I decap. I tried that once, and said screw this, hahaha.

I'd be interested in seeing that. I have a friend who does 3D printing who could likely run one off for meI should draw a 3d file in SketchUp for people to look at. I also have a buddy that does CNC machining, and I thought about having him make me one, but he just doesnt have the time.

Maybe not rebuild it, but it never hurts to polish the mating surfaces and clean the flash off the cast pieces.You're killing me here guyswith my LNL all I did was adjust it. Looks like I'm going to have to rebuild it when I get it to make it work.

I went a bit overboard and painted some parts to match the press

SC_Dave

Member

I swear i have not done any of this to mine

I did put some dry lubricant between the mating surfaces and on the ball end of the push rod but that's about it. I load 175-200 rounds a week and have about 5-7k on the case feeder. Not a lot probably compared to what you guys load.

I do like all of the engineering that has been put into these mods though. I may try the 12 ga shell mod just to stop the 9mm cases that bounce once in a while. It only a few but why not reduce that to zero with such a easy fix.

I love seeing what other do with their presses!

SCD

I did put some dry lubricant between the mating surfaces and on the ball end of the push rod but that's about it. I load 175-200 rounds a week and have about 5-7k on the case feeder. Not a lot probably compared to what you guys load.

I do like all of the engineering that has been put into these mods though. I may try the 12 ga shell mod just to stop the 9mm cases that bounce once in a while. It only a few but why not reduce that to zero with such a easy fix.

I love seeing what other do with their presses!

SCD

I wet tumble also, but I don't deprime first. Since I'm not using the pins and primer pockets aren't a major issue for me, I don't need the flow through the cases

I'd be interested in seeing that. I have a friend who does 3D printing who could likely run one off for me

I take my pins out for some stuff, mostly cleaning range rifle brass a little bit before I get on a sizing run.

Ill see what I can do with drawing something up this weekend. Shouldnt take me real long. Im not sure on the wear resistance of the plastic from a 3d printer though. Delrin is pretty tough stuff, and is self lubricating.

SC_Dave

Member

Where can i get delrin Kaldor? I have a couple of uses for it.

Sorry to derail the post Reeferman!

Sorry to derail the post Reeferman!

Reeferman

Member

- Joined

- Jan 9, 2013

- Messages

- 1,259

Where can i get delrin Kaldor? I have a couple of uses for it.

Sorry to derail the post Reeferman!

Oh that's ok by the sounds of things I'll be needing some as well!!!

SC_Dave

Member

Hahaha. I doubt you will need help. But, if you do I'll help where I can. I didn't have any trouble to speak of getting mine up and running and im that special kind of dumb you read about in medical books.

Blue68f100

Member

I had that problem early on and traced it down to 2 areas. First the delrin guide rod around the push rod that pushes on the wiper was backing out(up). I ended up using some sealant to fix it in place. The gaulling on mine was happening around the shoulder bolt. I took a file and smoothed it out. Then applied wheel bearing grease to the spring and contacting surfaces. Have not had a problem since, ~25k rounds. I use mine to deprime before wet cleaning, so it gets a lot more cycles than the round count. As far as the 9mm bouncing, I did something similar to the 12 ga hull. I found a piece of plastic pipe and and slit it, to allow it to slip over. Either walkalone or bds used some 1/2" sch 10 pvc pipe, for theirs.

Where can i get delrin Kaldor? I have a couple of uses for it.

Sorry to derail the post Reeferman!

Go to McMaster Carr. You can buy it in sheets. I have a machinist that gets me pieces of it as I need it, but if I needed to buy it, thats where I would go.

For you guys who are putting a shotgun hull on the drop tube are you changing from large to small or will what this guy does work?

I use a shotgun hull because its the perfect size to fit over the drop tube. And when I swap calibers, I just pull it off one, slide it on the other. Easy peasy

DRAINSMITH

Member

When ever we run into problems it seams that we want to blame that damn Micky Mouse engineer. Later on we normally find out that the real problem lies with Goofy. That is the guy looking back at us in the mirror in the morning.

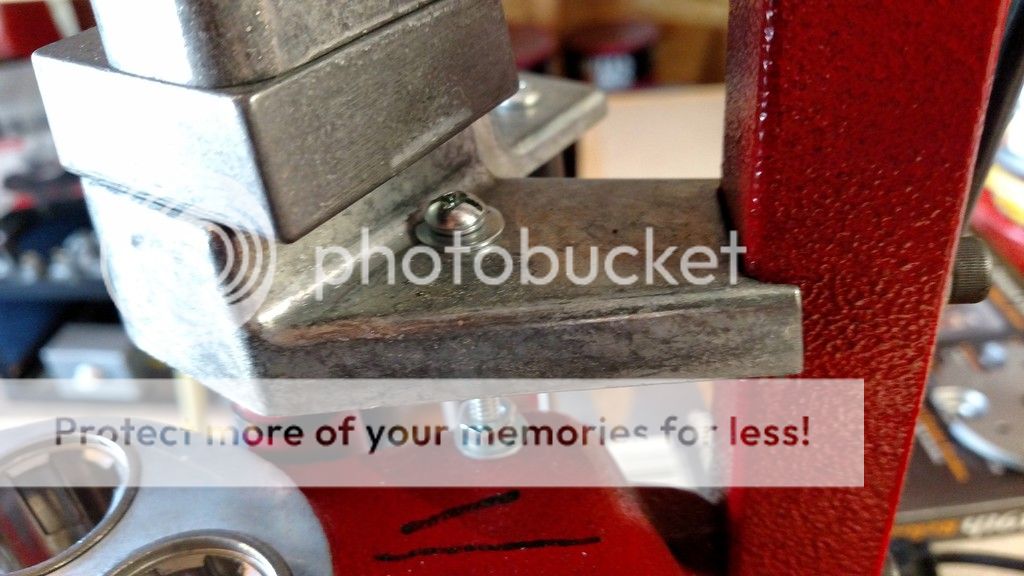

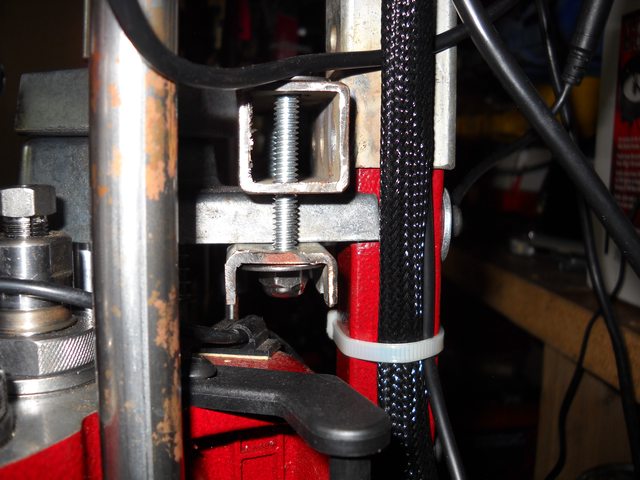

But Kaldor you have found the same Micky Mouse problem that I have run into.And that is the pivot body twisting on a single bolt and nut causing the case to be dropped off to far to the left. But unlike you I didn't have the stones to drill into my press. So I built a bracket to hold mine level. The bracket I built is held on to the case feeder stand upper and lower by both bolts.

Now I have 4 Ammo Plants and only 2 have the problem of shifting. There is no rhyme or reason why one will cant and the next one won't. But there is a fix.

But Kaldor you have found the same Micky Mouse problem that I have run into.And that is the pivot body twisting on a single bolt and nut causing the case to be dropped off to far to the left. But unlike you I didn't have the stones to drill into my press. So I built a bracket to hold mine level. The bracket I built is held on to the case feeder stand upper and lower by both bolts.

Now I have 4 Ammo Plants and only 2 have the problem of shifting. There is no rhyme or reason why one will cant and the next one won't. But there is a fix.

When ever we run into problems it seams that we want to blame that damn Micky Mouse engineer. Later on we normally find out that the real problem lies with Goofy. That is the guy looking back at us in the mirror in the morning.

But Kaldor you have found the same Micky Mouse problem that I have run into.And that is the pivot body twisting on a single bolt and nut causing the case to be dropped off to far to the left. But unlike you I didn't have the stones to drill into my press. So I built a bracket to hold mine level. The bracket I built is held on to the case feeder stand upper and lower by both bolts.

Now I have 4 Ammo Plants and only 2 have the problem of shifting. There is no rhyme or reason why one will cant and the next one won't. But there is a fix.

Its no issue drilling into the press, and I wouldnt think Hornady would void a warranty from it, but who knows. The LnL press itself is dang fine, runs as good as any 650 Ive seen, but the *&($%#&*))#$ing case feeder, some days I wanted to smash it, lol.

Heres a couple more pics. Takes about 10 minutes and $1.00 worth of hardware to make the a more "elegant" fix

And if you look at that last pic, you can see how my bracket had a bunch of movement and was twisting because the paint is scratched away.

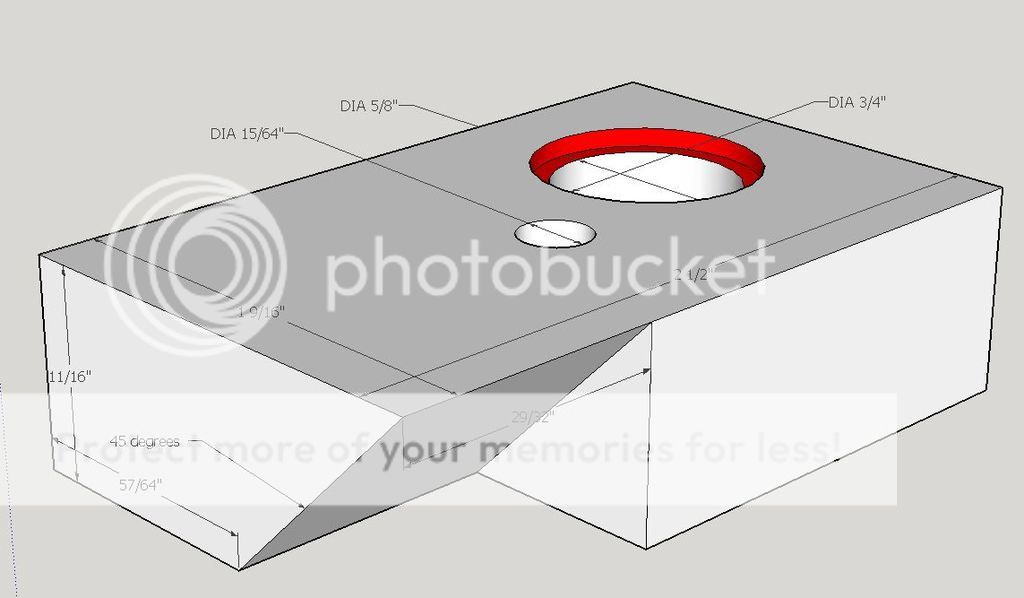

Here is a couple more pics of the block.

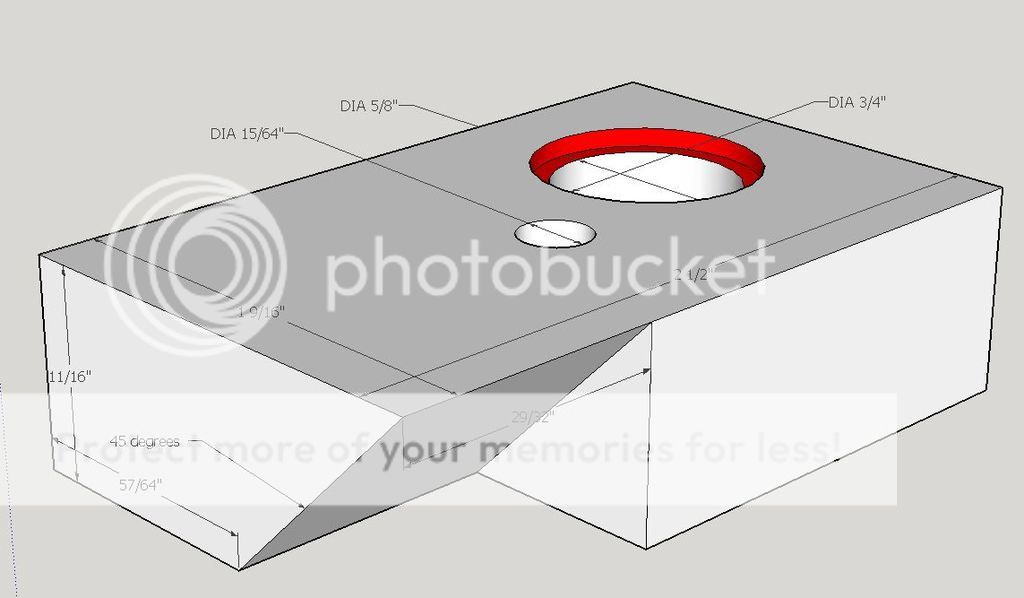

First a Sketchup drawing. If you have interest in the actual Sketchup file, Ill put it up on my Google Drive account and you can download it. Keep in mind, these measurements are taken with a calipers, and Im eyeing it as close as I can.

In this drawing you can see the red area. I started with a 3/4" thick piece of Delrin and cut it to thickness on my table saw. What I did was used a 3/4" spade bit in my drill press and drilled down about a 1/16" as this establishes the top sizing of the tapered hole. Then I finished the hole thru with a 5/8" bit. I finished the taper in the hole with a round rasp and a Dremel. The 45 was cut in with a fine tooth hand saw, leaving a little extra and finished with a flat file. The 15/64" hole was supposed to be a 1/4" but I think I used a 5/16" automotive stud so pick your stud and drill accordingly. Exact locations of holes are not in this pic but can be added to the drawing easily. I also added the small eye hook for the spring on the backside of the block that you cant see. I added an eye to the frame of the case feeder to attach to.

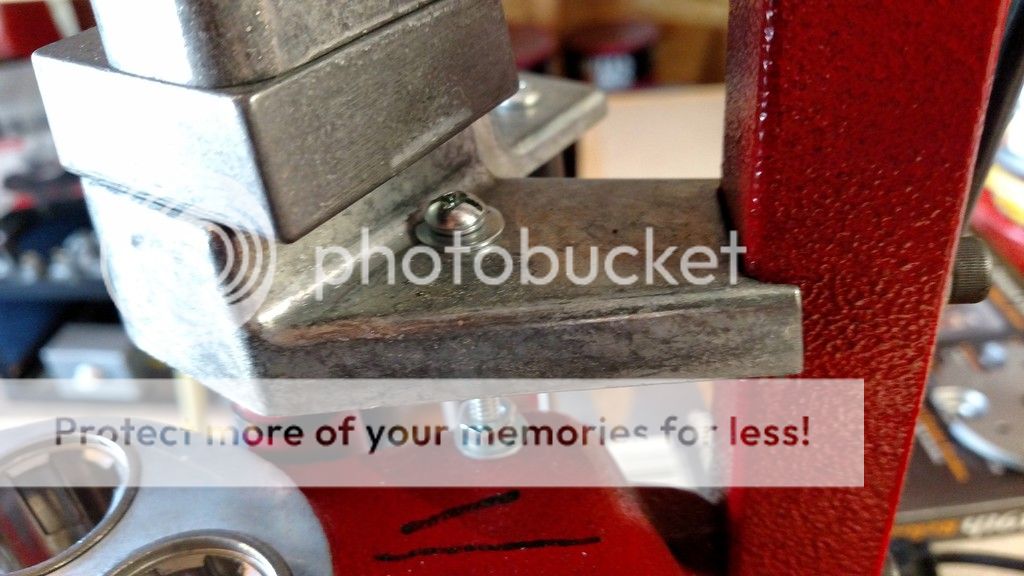

As far as mounting the pivot, a couple pics are worth 1000's of words...

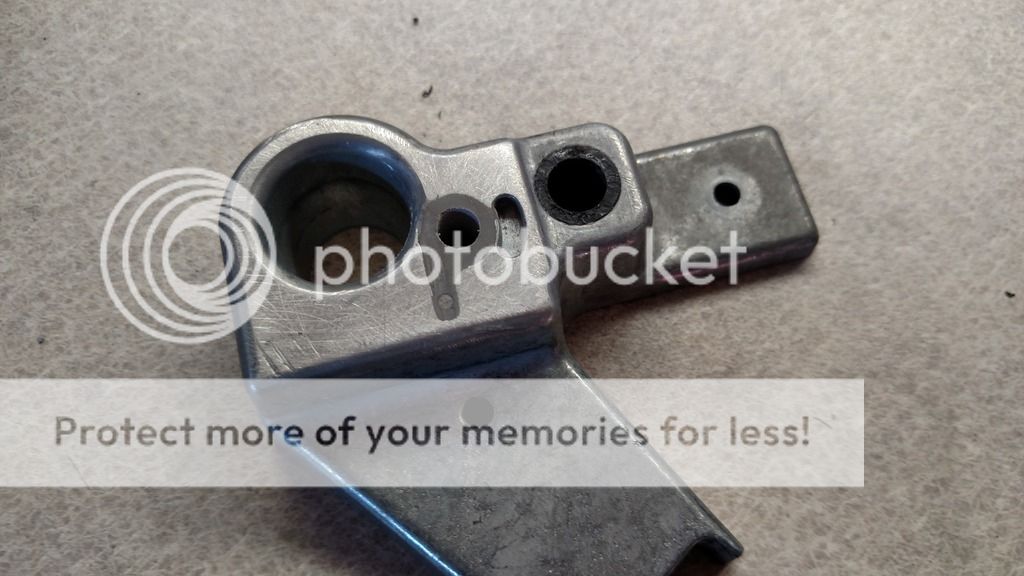

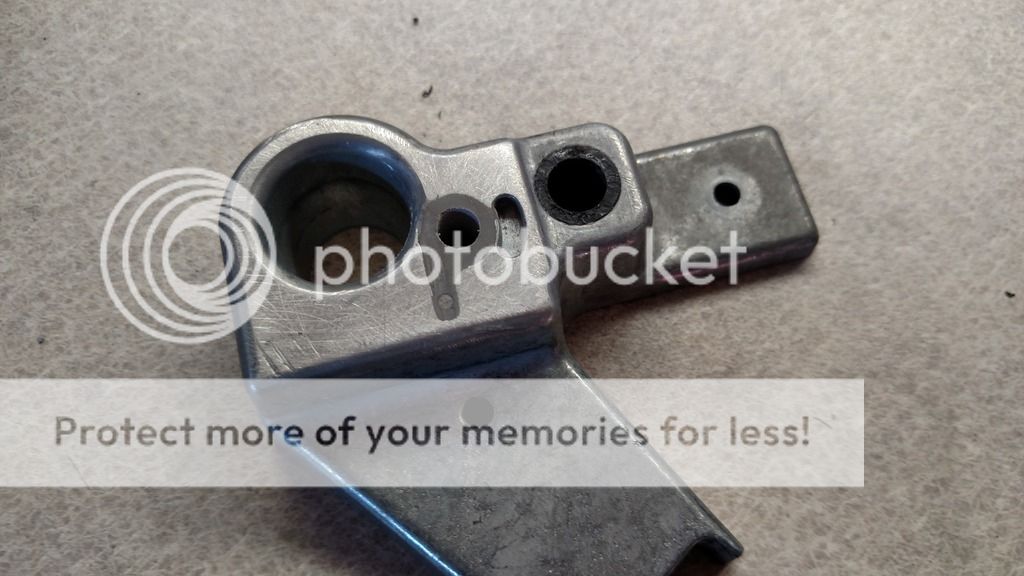

JB Weld to fill in the hole on the block. I would have used Devcon like what I use for bedding rifles, but I was all out and didnt want to buy $25 worth of materials for a $3 job. I think I plugged the hole in the bottom to keep it from running out.

Sanded JB Weld off smooth. Not perfect, but good enough. In hindsight I should have filled the hole for the little stop pin Hornady uses as it is not necessary.

Hole tapped for 5/16" stud. When you drill and tap this, use a drill press and drill from the bottom. The cheese grade pot metal is stronger than the JB Weld and youll want to start the tap in the metal and carry into the JB Weld. From this point just thread in the stud, and add a nut to the bottom of it to keep it from moving about. See the heavy scoring on the lower left corner? Thats how bad my flipper was galling. Thats why I decided to fix it permanently.

First a Sketchup drawing. If you have interest in the actual Sketchup file, Ill put it up on my Google Drive account and you can download it. Keep in mind, these measurements are taken with a calipers, and Im eyeing it as close as I can.

In this drawing you can see the red area. I started with a 3/4" thick piece of Delrin and cut it to thickness on my table saw. What I did was used a 3/4" spade bit in my drill press and drilled down about a 1/16" as this establishes the top sizing of the tapered hole. Then I finished the hole thru with a 5/8" bit. I finished the taper in the hole with a round rasp and a Dremel. The 45 was cut in with a fine tooth hand saw, leaving a little extra and finished with a flat file. The 15/64" hole was supposed to be a 1/4" but I think I used a 5/16" automotive stud so pick your stud and drill accordingly. Exact locations of holes are not in this pic but can be added to the drawing easily. I also added the small eye hook for the spring on the backside of the block that you cant see. I added an eye to the frame of the case feeder to attach to.

As far as mounting the pivot, a couple pics are worth 1000's of words...

JB Weld to fill in the hole on the block. I would have used Devcon like what I use for bedding rifles, but I was all out and didnt want to buy $25 worth of materials for a $3 job. I think I plugged the hole in the bottom to keep it from running out.

Sanded JB Weld off smooth. Not perfect, but good enough. In hindsight I should have filled the hole for the little stop pin Hornady uses as it is not necessary.

Hole tapped for 5/16" stud. When you drill and tap this, use a drill press and drill from the bottom. The cheese grade pot metal is stronger than the JB Weld and youll want to start the tap in the metal and carry into the JB Weld. From this point just thread in the stud, and add a nut to the bottom of it to keep it from moving about. See the heavy scoring on the lower left corner? Thats how bad my flipper was galling. Thats why I decided to fix it permanently.

- Status

-

Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 484

- Replies

- 3

- Views

- 461

- Replies

- 3

- Views

- 1K

- Replies

- 14

- Views

- 552