capreppy

Member

Had my 223 rebarreled from a 24" 1/9 twist varmint profile to a 30" 1/7 twist bull profile (for my recoil sensitive members of my family plus the faster twist also allows me to run the 75 Amax and heavier).

I am doing load development for this rifle. I'm VERY fond of the Hornady 50gr Z-Max because they are cheap and shoot very well. I was able to shoot consistent 1/2 MOA groups out of the old barrel. When I was doing load development, I was able to shoot a 1/4 MOA group using Win headstamp brass, Fed 205M (Small Rifle Match Primer), 24gr H322. I had other loads as well, but this was obviously the load to run with.

I loaded up 50 more to run over the chrono (MagnetoSpeed v3). As I was running the loads over the chrono, I could see where each round landed. When a round was a little off, I could look over at the chrono and see the difference in the speed. This load on average runs 3350fps. When my ES is single digit, yes I saw one ragged hole. In general, my ES was an average of 20.

For this rifle, I have 4k pieces of Win headstamped brass dedicated to it. I like to load thousands when I have the downtime (like right now cause I'm unemployed, but that is about to end).

My brass is once or twice fired brass. I am putting the brass aside and plan to have a friend anneal them. I believe (need confirmation here) that this should help some with ES.

I dispense each load with an RCBS Chargemaster. The H322 is a very small extruded powder and meters very well. The Chargemaster meters to the tenth of a grain. I know I'm not going to get small single digit ES (that requires more expensive equipment that I have zero desire to get)

What are some things that I can do to help reduce my ES?

Neck Turning? This is NOT a tight necked chamber.

I know that weighing the brass for consistency will help and that is obviously a free upgrade (just requires time).

Other options? Or am I chasing the proverbial tail. :banghead:

I am doing load development for this rifle. I'm VERY fond of the Hornady 50gr Z-Max because they are cheap and shoot very well. I was able to shoot consistent 1/2 MOA groups out of the old barrel. When I was doing load development, I was able to shoot a 1/4 MOA group using Win headstamp brass, Fed 205M (Small Rifle Match Primer), 24gr H322. I had other loads as well, but this was obviously the load to run with.

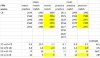

I loaded up 50 more to run over the chrono (MagnetoSpeed v3). As I was running the loads over the chrono, I could see where each round landed. When a round was a little off, I could look over at the chrono and see the difference in the speed. This load on average runs 3350fps. When my ES is single digit, yes I saw one ragged hole. In general, my ES was an average of 20.

For this rifle, I have 4k pieces of Win headstamped brass dedicated to it. I like to load thousands when I have the downtime (like right now cause I'm unemployed, but that is about to end).

My brass is once or twice fired brass. I am putting the brass aside and plan to have a friend anneal them. I believe (need confirmation here) that this should help some with ES.

I dispense each load with an RCBS Chargemaster. The H322 is a very small extruded powder and meters very well. The Chargemaster meters to the tenth of a grain. I know I'm not going to get small single digit ES (that requires more expensive equipment that I have zero desire to get)

What are some things that I can do to help reduce my ES?

Neck Turning? This is NOT a tight necked chamber.

I know that weighing the brass for consistency will help and that is obviously a free upgrade (just requires time).

Other options? Or am I chasing the proverbial tail. :banghead: