I've loaded over 1000 rounds now, so my statistics are a bit better:

4 no prime

1 smile

1 crushed, sideways primer

1 royal screw up. Not sure what happened but the plate wouldn't advance at the bottom of the stroke, nothing seemed amiss at the top of the stroke. I emptied the pipeline except I couldn't remove the case in the priming station. When I removed the shell plate, I saw a mangled primer (I assumed it was live, but it could have been one that didn't completely drop and dragged into the priming station. It was preventing the priming pin from dropping which prevented the shell holder from rotating. Cleaning this up and reassembling everything has been fine since -- that was 3-400 rounds ago.

With the original Gen 1 primer system I'd have been thrilled to have "only" these failures in 100 rounds.

Basically a happy camper now!

Well, this happiness sure didn't last very long.

I had one more no primer round which I discovered while loading magazines in the inital ~1400 rounds that had slipped through moving from the catch bin to my ammo storage can, so the total was five instead of four no primer. IF that was all, I'd not be posting this.

Seems the "royal screw-up" was a harbinger of things to come

After loading ~400 more rounds, thinking it was clear sailing with the Loadmaster, things went downhill fast. Couldn't go more than 20-30 rounds without a primer system failure -- crushed, sideways, upside down, or royal screw-up.

The crushed, sideway, and upside down failures just waste components, which is frustrating enough. But the royal screw-ups waste a large amount of time removing the cases from the pipeline and removing the shell plate. After about a dozen more of these I'm ready to take the stupid thing out and blow it up with Tannerite, I'll be sure to video it for youTube!

I don't see how a solution is possible, if the Gen 3 priming system is worn out after this few rounds, its definitely time to junk the Loadmaster.

I removed the tool head and manually pushed the primer arm at the bottom and fed through 100 primers, removing each one from the priming pin at the top of the stoke. I had the following failures:

# - failure type

2 - Upside-Down -- self explanatory, but I do not understand how it happens -- I could see the brass colored anvil or red primer compound every time I pushed the primer arm at the bottom of the stroke, but still two ended up on top of the pin upside-down.

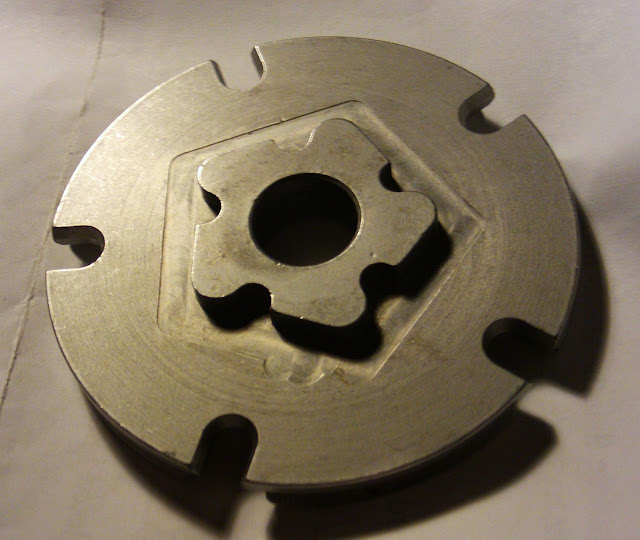

1 - Off Track -- this seems to be the royal screw-up as the primer wedges in between the primer pin and the primer arm. When I remove the shell plate on these the primer pin "snaps" back down and the mangled primer generally flies up and into the center tube.I've a photo attached.

Without a case the primer flips up and the primer pin retracts as I lower the ram.

3 - Sideways -- likely an upside-down that only got half ways there.

2 - Too Far In -- These are scary and most likely to be the ones that detonate. The primer somehow is pushed beyond the inside edge of the pin and hangs on the inside lip of the shell plate as the pin rises.

I just don't see any possibility of a fix at this point as it now seems as bad as my original Gen 1 priming system was after less than 2000 rounds loaded

So before I give this thing a starring role in a "hold my beer and watch this" youTube video, anybody got a clue I've somehow overlooked as to how I might solve these issues?

I labeled all the shell holder locations and the failures seemed uniformly distributed (the one in the photo was the first failure at #3, locations #2 & #4 had previously different failures). Never did the primer rod look the least bit off-center.