ballman6711

Member

I've never loaded coated bullets but have been wanting to try some, so I added 500 acme 185gr swc's to an order I placed a few days ago for my 45acp.

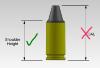

From my research, I understand that I need to expand the case enough to not shave the coating. I've also read that I should use lead or plated data.

I'm planning to use lead data and work my loads up as usual, using W231 and vv n320.

Am I missing anything? Any tips?

I've been reloading for almost two years and find I still have a lot to learn.

Thanks in advance.

chris

From my research, I understand that I need to expand the case enough to not shave the coating. I've also read that I should use lead or plated data.

I'm planning to use lead data and work my loads up as usual, using W231 and vv n320.

Am I missing anything? Any tips?

I've been reloading for almost two years and find I still have a lot to learn.

Thanks in advance.

chris