uncle.45

Member

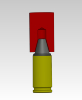

The swc seating stem with my SDB only contacted the nose of the bullets, so I drilled the flat portion several thousandths, and fitted it to my most-used bullets with epoxy so it contacts the taper instead.

My 1911s like .45acp 200gr swcs at 1.260" , but even with the modified seating stem, the oal ranges from 1.2585 to 1.2635" .

My desired oal is in the middle of this range, but the OCD part of me wants a variance of +/-.001" , not +/-.0025" .

Do you find this oal range acceptable?

Am I just too OCD for my own good?

I appreciate your input!

My 1911s like .45acp 200gr swcs at 1.260" , but even with the modified seating stem, the oal ranges from 1.2585 to 1.2635" .

My desired oal is in the middle of this range, but the OCD part of me wants a variance of +/-.001" , not +/-.0025" .

Do you find this oal range acceptable?

Am I just too OCD for my own good?

I appreciate your input!