Hi everybody I hope someone be able to help me figure out my problem so here it goes.

I bought a Hornady Lock n load AP to do some reloading, I get everything setup and start to load 9mm using RCBS Carbide Dies. This works but every other case or so doesn't go into the sizing die properly I have to pull back on the case toward the center of the shell plate to guide it in.

This gets annoying quick so I call Hornady customer service and we sit on the phone for about twenty minutes adjusting pawls etc to no avail, at the end the tech says it must be that the RCBS dies do not have enough taper to guide the cases in properly. So I decide to sell the RCBS dies on ebay and buy a set of Hornady New Dimension nitrade dies to solve the problem.

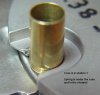

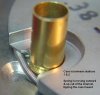

I get my new Hornady dies clean them as told in the insructions and start using them. The problem I have now is when I run a case up into the resizing decapping die it is very stiff and when I run it back down it seems to take some force to get the case back out of the die. When the case does come out about the top 25-30% is scratched up all the way around the case and about down to 75% of the way down is lightly scratched. This can't be normal because it didn't happen with the rcbs dies. I bought some hornady one shot case lube but this did not really help that much.

Does anybody have any idea what The problem could be? Any help is appreciated

I bought a Hornady Lock n load AP to do some reloading, I get everything setup and start to load 9mm using RCBS Carbide Dies. This works but every other case or so doesn't go into the sizing die properly I have to pull back on the case toward the center of the shell plate to guide it in.

This gets annoying quick so I call Hornady customer service and we sit on the phone for about twenty minutes adjusting pawls etc to no avail, at the end the tech says it must be that the RCBS dies do not have enough taper to guide the cases in properly. So I decide to sell the RCBS dies on ebay and buy a set of Hornady New Dimension nitrade dies to solve the problem.

I get my new Hornady dies clean them as told in the insructions and start using them. The problem I have now is when I run a case up into the resizing decapping die it is very stiff and when I run it back down it seems to take some force to get the case back out of the die. When the case does come out about the top 25-30% is scratched up all the way around the case and about down to 75% of the way down is lightly scratched. This can't be normal because it didn't happen with the rcbs dies. I bought some hornady one shot case lube but this did not really help that much.

Does anybody have any idea what The problem could be? Any help is appreciated

Last edited: