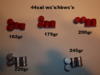

Well, I loaded up some wadcutter rounds in .38 Spl and I made 3 different lengths. The measurements are COL (cartridge overall length) I’ll bet you can’t guess which ones won’t load in a .38 Spl cylinder…

I took my 3 snubnosed .38s to the range.

My S&W 36, my Colt DS and my S&W 442

I decided to only try 2 powder charges in 15 cartridges of each of the 3 lengths. Under each 148 grain Bear Creek Supply button nosed wadcutter I tried 3.2 grains and 3.4 grains of Universal powder. I decided to shoot at 10 yards as 5 yards just seemed too close for a good indicator of accuracy.

I was shooting one handed, right hand unsupported. My left hand is still in a brace from surgery.

From the model 36:

The two top targets are 3.2 grain loads.

#1 is a flush loaded WC

#2 is with the bullet COL at 1.240”

Not sure why #2 hit to the right but a nice group.

The 2 bottom targets are 3.4 grain loads.

The targets with the bullets a bit long in the case at COL 1.240” seem to group better.

Here is what the 1.450” cartridges looked like when loading into my model 36. I literally slapped myself in the forehead, cussed then laughed…I should have known better.

Then came the Colt Detective Special doing the same scenario as the model 36. I almost didn’t bother posting this as accuracy was just plain awful!

The first round of the 3.2 grain load hit the metal target holder on the left side. I was aiming for the bullseye on both top targets. I think it’s safe to say the DS doesn’t like the 3.2 grain load, especially the flush mounted WC cartridge.

For the bottom 2 targets I held the sights at a 6 O’clock hold 5 rounds on each. I don’t think my DS likes slow cartridges. The “Oops” hole above #1 was because I went to fast when aiming and pulling the trigger.

I am not posting the target I shot with my 442. It was downright embarrassing.

I do believe that after reading all of your suggestions and recommendations that I am over crimping my loads. I also think that leaving some of the bullet out of the cartridge like the 1.240” loads might be the way to go, but it is obvious I have some more tinkering to do. I think I need to load up some more and try them with my model 10 and my model 19