LiveLife

Member

Remember this "No Shake" R&D primer tray thread when we had primer feeding issue down from primer tray on early production release of Six Pack Pro/Pro 6000 kit? (Which was addressed with larger agitator pin in new primer attachment chute/trough) - https://www.thehighroad.org/index.p...s-no-pin-no-shake-primer-feed-options.913724/

During multiple brainstorming and fabricating various contraptions to reliably feed primers, I went back to basics and started with most reliable feed mechanism of "No Shake" single column primer device which obviously fed reliably. (BTW, Dillon/Hornady press mounted and many bench mounted priming devices use single column primer feed without the need for "shake")

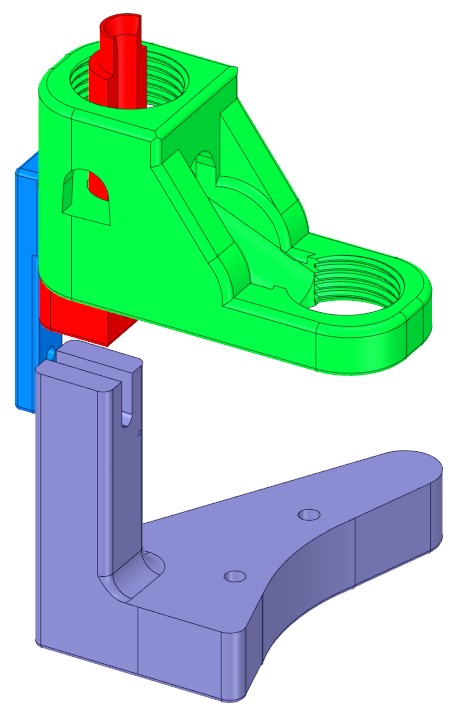

So I thought, "How can I make this single column feed practical with a tray of 100 primers?" and came up with this multi-column device that could use a "gate" to switch between columns. (BTW, 3-column primer feed device was about 7.5" long and could accommodate primer tray of 100 primers)

During multiple brainstorming and fabricating various contraptions to reliably feed primers, I went back to basics and started with most reliable feed mechanism of "No Shake" single column primer device which obviously fed reliably. (BTW, Dillon/Hornady press mounted and many bench mounted priming devices use single column primer feed without the need for "shake")

"Extension tube 10" long held over 50 Winchester LP primers ... This is how it looks inserted into the primer chute/trough and of course, it was 100% reliable without any concern of pin making sufficient contact with frame column/groove rings (I removed the pin for testing as it was not needed). With an adapter at the top to accommodate Lee primer tray, you could refill the chute/trough extension rather quickly."

So I thought, "How can I make this single column feed practical with a tray of 100 primers?" and came up with this multi-column device that could use a "gate" to switch between columns. (BTW, 3-column primer feed device was about 7.5" long and could accommodate primer tray of 100 primers)

Last edited: