Durango_Dave

Member

You can't carry around a really old revolver with 6 live rounds or one may go off accidentally.

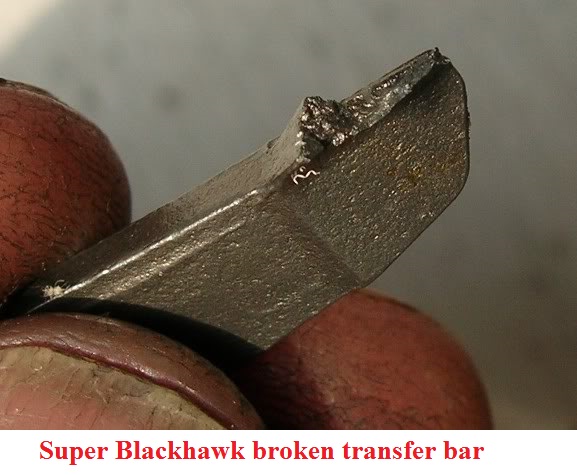

Manufacturers have resolved this problem in different ways. Ruger uses a transfer bar. I understand the how and why behind them.

Smith and Wesson uses both a hammer block and a rebounding hammer.

The top circle is the hammer block. The bottom circle is the rebounding hammer slide. They both prevent the firing pin from hitting the primer unless the trigger is pulled all the way back as the hammer hits the primer.

Just trying to understand, why does S&W use both methods? That rebounding hammer alone seems safe enough. It's far more sturdy than the tiny notch on the hammer of a half cock safety. Are there any guns that only have a rebounding hammer? I see S&W using both.

I have a S&W Model 29 made in 1988. It has the firing pin on the hammer. S&W no longer uses that design. Why? What's the problem with a firing pin on the hammer? Correct me if I'm wrong but I don't think there are any double action revolvers made anymore with a firing pin on the hammer.

These are simple questions. I'm just trying to understand revolver design.

Manufacturers have resolved this problem in different ways. Ruger uses a transfer bar. I understand the how and why behind them.

Smith and Wesson uses both a hammer block and a rebounding hammer.

The top circle is the hammer block. The bottom circle is the rebounding hammer slide. They both prevent the firing pin from hitting the primer unless the trigger is pulled all the way back as the hammer hits the primer.

Just trying to understand, why does S&W use both methods? That rebounding hammer alone seems safe enough. It's far more sturdy than the tiny notch on the hammer of a half cock safety. Are there any guns that only have a rebounding hammer? I see S&W using both.

I have a S&W Model 29 made in 1988. It has the firing pin on the hammer. S&W no longer uses that design. Why? What's the problem with a firing pin on the hammer? Correct me if I'm wrong but I don't think there are any double action revolvers made anymore with a firing pin on the hammer.

These are simple questions. I'm just trying to understand revolver design.

Last edited: