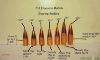

I have put the scope base and rings on this gun and loaded up a few primerless, powderless rounds from the brass and bullets I am starting with. It is comprised of a Sierra 53 grain HP bullet, and LC brass I have sized body and neck with Redding Competition micrometer bushing neck, and their matching Body die, trimmed to 1.75."

Sierra calls for 2.250 for this bullet, and 2.260 for the 69 grain match king I also planned to load, but the 53 grain is giving me trouble. I set them for 2.250 inches and chambered it, and it shrank in length to 2.240-2.238 COL.

I inserted another by hand in the chamber, which slid in easily until the last bit, when a very slight resistance was encountered. I removed the bullet, re neck sized and reseated the bullet. put it in, extracted, now it grew to almost 2.270! I wondered if that slight resistance was felt pulled the bullet out as the round was extracted?

It then dawned on me that this new gun had not only never been fired, it hadnt been cleaned of the factory gunk, I cleaned it, and it did seem to help considerable with the slight resistance, but still shrank from 2.250 to 2.240 or so.

Examining the bullets tip, there are marks on it, not sure if those are rifling marks or not.

Who else is loading for this gun and have you had similar trouble with bullets in the 2.250 and longer?

excedrin headache # 53...

Russellc

Sierra calls for 2.250 for this bullet, and 2.260 for the 69 grain match king I also planned to load, but the 53 grain is giving me trouble. I set them for 2.250 inches and chambered it, and it shrank in length to 2.240-2.238 COL.

I inserted another by hand in the chamber, which slid in easily until the last bit, when a very slight resistance was encountered. I removed the bullet, re neck sized and reseated the bullet. put it in, extracted, now it grew to almost 2.270! I wondered if that slight resistance was felt pulled the bullet out as the round was extracted?

It then dawned on me that this new gun had not only never been fired, it hadnt been cleaned of the factory gunk, I cleaned it, and it did seem to help considerable with the slight resistance, but still shrank from 2.250 to 2.240 or so.

Examining the bullets tip, there are marks on it, not sure if those are rifling marks or not.

Who else is loading for this gun and have you had similar trouble with bullets in the 2.250 and longer?

excedrin headache # 53...

Russellc