You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Very, very, very unusual annealing method

- Thread starter gamestalker

- Start date

- Status

-

Not open for further replies.

gamestalker

member

These were some of the responses I wanted to hear. I'm wondering if he isn't maybe adding something else to the oil, as was suggested by some of you, and it is his little secret? I haven't tried it and doubt I ever will. Everything I know about reloading has come from a book and authored by well acredited profesionals. Never have I heard anything about this process or anything even simular. I'll kepp my eye's open on this to see if someone can maybe uncover the secret element of his process. There just has to be more to it than just the motor oil, rather dirty motor oil.

Thanks guys for your interest.

Thanks guys for your interest.

Brass has been worked for as long time.

It is rather unlikely he has found anything new.

More likely he is getting away by the skin of his teeth.

You might ask him how many loadings he gets before primer pockets are loose.

Of course the brass may be so soft it is flowing around the primer with each shooting...

It is rather unlikely he has found anything new.

More likely he is getting away by the skin of his teeth.

You might ask him how many loadings he gets before primer pockets are loose.

Of course the brass may be so soft it is flowing around the primer with each shooting...

It is termed quench annealing. The only way to harden brass is by cold working. I will have to look at Cu-Zn phase diagram, but off the top of my head, I think he is heating the brass to a higher temperature than necessary and holding the temperature far too long.

It is termed quench annealing. The only way to harden brass is by cold working. I will have to look at Cu-Zn phase diagram, but off the top of my head, I think he is heating the brass to a higher temperature than necessary and holding the temperature far too long.

You normally quench brass when annealing it to make sure no heat moves into the head of the case to soften it.

and when it is finished it looks grey, sort of like steel. When he seats his bullets the neck tension is tighter than anything I've ever felt.

The surface finish may be what is making the neck tension feel tighter. Basically I'm saying that the rough gray surface finish is grabbing the soft copper jacket of the bullet. IMO

I would never adopt this way of treating a case, I don't like the sounds of it at all and I have over 40 yrs experience.

blarby

Member

"it is termed quench annealing. The only way to harden brass is by cold working. I will have to look at Cu-Zn phase diagram, but off the top of my head, I think he is heating the brass to a higher temperature than necessary and holding the temperature far too long."

No.

No.

This is far beyond quench annealing, both in its intent and application.

"The surface finish may be what is making the neck tension feel tighter. Basically I'm saying that the rough gray surface finish is grabbing the soft copper jacket of the bullet. IMO"

Thats the glazing me thinks is doing the trick.... and from what i'm seeing, he's either got some interesting engine components in that motor hes tapping as a well, or you are only getting half the story on the oils' true content as you suspected.

I'd like a serious professional metallurgist to weigh in on this one.....tell him to bring that accursed lead/gold rock when he comes

No.

No.This is far beyond quench annealing, both in its intent and application.

"The surface finish may be what is making the neck tension feel tighter. Basically I'm saying that the rough gray surface finish is grabbing the soft copper jacket of the bullet. IMO"

Thats the glazing me thinks is doing the trick.... and from what i'm seeing, he's either got some interesting engine components in that motor hes tapping as a well, or you are only getting half the story on the oils' true content as you suspected.

I'd like a serious professional metallurgist to weigh in on this one.....tell him to bring that accursed lead/gold rock when he comes

I believe Gamestalker's description of his friend's process, but...

his friend 'claims'

Our good friend Ambidextrous says, "It's difficult to argue with empirical evidence," but quite honestly we haven't seen any.

We're all open to what the metallurgists say,

and we might just learn something innovative and new,

but don't forget that

we don't have any empirical evidence yet. There may be no advantage.

his friend 'claims'

I wish I had a nickel for every jackass who made outlandish claims (which no one else happens to witness) regarding their cars, guns, ammo, computers, pocket knives, boots, stereos, driveways, tools, landscape, roofs, motorcycles, pavement, tires, brakes, beer coolers, radios, wristwatches, mobile phones, and everything else a braggart can brag about.- it stops the brass from ever needing the shoulder bumped

- primer pockets don't get loose

- brass will out last any no matter what dies they are using

- exceed listed maximum data

- improved accuracy.

Our good friend Ambidextrous says, "It's difficult to argue with empirical evidence," but quite honestly we haven't seen any.

We're all open to what the metallurgists say,

and we might just learn something innovative and new,

but don't forget that

we don't have any empirical evidence yet. There may be no advantage.

I wish I had a nickel for every jackass who made outlandish claims (which no one else happens to witness) regarding their cars, guns, ammo...

My ammo is better than anyone's and my car is pretty damn fast.

Owen

Moderator Emeritus

No."it is termed quench annealing. The only way to harden brass is by cold working. I will have to look at Cu-Zn phase diagram, but off the top of my head, I think he is heating the brass to a higher temperature than necessary and holding the temperature far too long."

This is far beyond quench annealing, both in its intent and application.

You seem to know more about this than the rest of us, could you tell us about this metal glazing process? Do you have a reference?

I've been selecting surface treatments for metals for about 15 years now, and I'm not familiar with it.

zinc dialkyldithioposphate is the lubricating additive in all motor oils (1%). he may be adding more zinc. also, the annealing process for brass usually takes between 1/2 to one hour at temperature. i don't think heating to red hot for one minute is long enough to grow crystals. could be long enough to stress relieve the brass, though.

only a guess at this point, but very interesting concept.

murf

only a guess at this point, but very interesting concept.

murf

gamestalker

member

I called him yestrday to try and get a little bit more detail to this rediculously dangerous method. I asked him specifically what else he is doing or adding to his oil and he chuckled with a familiar chuckle I've come to know him for. I'm now certain something else is happening here, and frankly I don't think I want to know. Indeed based on his response, I'm not privey to what he may me adding this oil, if it's even oil? I remember the first time he did this some 20 yrs. or so back he put something in the oil but because I had just dropped by to pick up something up unrelated to reloading, so my attention wasn't on what he was doing. He's an electrician by trade, but I don't think anything used in his trade is involved here.

I only posted this with the hope someone could shed some light on it and I have indeed seen the light. I would never attempt this, and I would hope it wasn't a mistake to have posted it, in that I don't want someone to feel inspired to try it. I tried it with a piece of brass last night and the results were exactly consistent with what everyone else said, the brass was almost completely depleted of it's necessary properties and was so soft I was able to bend the mouth with my bare finger's. When I told him that on the phone he just laughed and said, so what's your point? he won't give it up and I'm not going to acknowledge this as worthy of further attention.

Again ya all, thanks for the feed back. And if by some chance someone discover's the possible secret here I would be elated to know just so i can devulge it to him, like your busted. We are best of friends and it would be awesome to be able to beat him at this one.

I only posted this with the hope someone could shed some light on it and I have indeed seen the light. I would never attempt this, and I would hope it wasn't a mistake to have posted it, in that I don't want someone to feel inspired to try it. I tried it with a piece of brass last night and the results were exactly consistent with what everyone else said, the brass was almost completely depleted of it's necessary properties and was so soft I was able to bend the mouth with my bare finger's. When I told him that on the phone he just laughed and said, so what's your point? he won't give it up and I'm not going to acknowledge this as worthy of further attention.

Again ya all, thanks for the feed back. And if by some chance someone discover's the possible secret here I would be elated to know just so i can devulge it to him, like your busted. We are best of friends and it would be awesome to be able to beat him at this one.

Remo223

member

Your buddy is not an idiot. He is up to something and not telling you all his tricks. He's adding something to the oil. Did you watch him dunk it in the oil? Is he pre-heating the oil? IF so, how hot? Is the oil smoking?These were some of the responses I wanted to hear. I'm wondering if he isn't maybe adding something else to the oil, as was suggested by some of you, and it is his little secret? I haven't tried it and doubt I ever will. Everything I know about reloading has come from a book and authored by well acredited profesionals. Never have I heard anything about this process or anything even simular. I'll kepp my eye's open on this to see if someone can maybe uncover the secret element of his process. There just has to be more to it than just the motor oil, rather dirty motor oil.

Thanks guys for your interest.

I'd say he is adding something to the oil and knows exactly what he is doing.

Just my hunch.

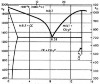

Here's an interesting figure from one of my old textbooks showing the different phases during the annealing of brass. Brass supposedly begins to glow a faint orange at about 950ºF at which point it's too soft for our use. It should be noted that for cartridge brass (70% Cu, 30% Zn), it only exists in the alpha phase up to about 950ºC.

From Materials Science and Engineering an Introduction by William D. Callister, Jr.

From Materials Science and Engineering an Introduction by William D. Callister, Jr.

blarby

Member

http://en.wikipedia.org/wiki/Glass-coated_wire

http://en.wikipedia.org/wiki/Powder_coating

http://swiftglass.com/index.php?option=com_content&task=section&id=7&Itemid=4

I mentioned powder coating ( which i'm sure you are allready aware of) as a reference simply to illustrate that you can coat metals with silicates, heat them, and obtain a coating.

Thats kinda what I think he's got going, something along that spectrum.

Supported in a proper chamber, it wouldn't matter how soft the brass was- it isn't detonating...its EXPANDING.

All he's done ( if this is really true) would be to find a very neat way to seal the distance (however small) between the cartridge exterior wall and the chamber wall.

If there was no where for the cartridge to expand to, all the energy would be forced out of the actual barrel, not wasted in expanding the case. The fact that he's apparently done it with a high heat flowing compound only works in his favor....not against it.

Personally I have my doubts. Theoretically ? Sure and plausible. Found it in the bottom of an oil pan ? Eh.... Thats where the doubts come in. BUT, we've discovered some miracle things in stranger places.

Silicate coatings of metals as listed above are surely used every day from the gamut of tradesman to scientists. If he's really found a way to extract this process from motor oil, I'm doing it tomorrow too

http://en.wikipedia.org/wiki/Powder_coating

http://swiftglass.com/index.php?option=com_content&task=section&id=7&Itemid=4

I mentioned powder coating ( which i'm sure you are allready aware of) as a reference simply to illustrate that you can coat metals with silicates, heat them, and obtain a coating.

Thats kinda what I think he's got going, something along that spectrum.

Supported in a proper chamber, it wouldn't matter how soft the brass was- it isn't detonating...its EXPANDING.

All he's done ( if this is really true) would be to find a very neat way to seal the distance (however small) between the cartridge exterior wall and the chamber wall.

If there was no where for the cartridge to expand to, all the energy would be forced out of the actual barrel, not wasted in expanding the case. The fact that he's apparently done it with a high heat flowing compound only works in his favor....not against it.

Personally I have my doubts. Theoretically ? Sure and plausible. Found it in the bottom of an oil pan ? Eh.... Thats where the doubts come in. BUT, we've discovered some miracle things in stranger places.

Silicate coatings of metals as listed above are surely used every day from the gamut of tradesman to scientists. If he's really found a way to extract this process from motor oil, I'm doing it tomorrow too

blarby

Member

@ 1858 : I apologize- however Your mixing of Celsius and Fahrenheit is confusing.

950 degrees Celsius is about 1750 Fahrenheit.

Brass glows orange at 950 Fahrenheit.

According to your handily supplied chart, this is right at the top of useful ductility- while at the base of tensile strength. Anyone who has hand annealed brass can state that the brass is still usable at this stage, it is simply "softened"

950 degrees Celsius is about 1750 Fahrenheit.

Brass glows orange at 950 Fahrenheit.

According to your handily supplied chart, this is right at the top of useful ductility- while at the base of tensile strength. Anyone who has hand annealed brass can state that the brass is still usable at this stage, it is simply "softened"

Remo223

member

^just one problem...he(the guy that's doing the annealing procedure) says primer pockets don't expand. he says neck tension is increased.

He's not annealing the copper/brass. He's altering the chemical composition somehow so that the new alloy tempers like steel rather than anneals like copper. I don't know if he's adding aluminum or beryllium or what.

He's not annealing the copper/brass. He's altering the chemical composition somehow so that the new alloy tempers like steel rather than anneals like copper. I don't know if he's adding aluminum or beryllium or what.

blarby said:Brass glows orange at 950 Fahrenheit.

That's what I wrote.

Remo223 said:He's not annealing the copper/brass. He's altering the chemical composition somehow so that the new alloy tempers like steel rather than anneals like copper. I don't know if he's adding aluminum or beryllium or what.

The OP clearly states "he drops it into a bowl of well used motor oil" so he's using oil as a carbon source. This "trick" has been used to carburize steel for years. Two other possibilities are that carbon is bonding with Cu to form CuC2 or Zn to form ZnC, but I'm not familiar with the kinetics of those reactions. I still think that carbon atoms are diffusing into the copper-zinc lattice and occupying interstitial sites.

I'd really like to see some groups from this guy comparing loads with cases before and after his annealing method.

Remo223

member

^that's probably the answer. My experience has been that when trying to solve a mystery, the simplest explanation is usually the right one.

rfwobbly

Member

Owen

Moderator Emeritus

the problem is that the time isn't long enough to introduce carbon.

also, the old timers weren't adding carbon by dropping steel parts into oil, the oil just controls the cooling rate. The time at temperature in the oil isn't long enough to add carbon to any significant depth. Unless of course the whole bucket of oil is in the oven at 1500 degrees for a few hours.

Liquid pack carburizing uses a molten salt bath. An example is Sodium Cynide, which would be in a bath at 1600 degF. to achieve a .001" deep case, a part made of 1020 steel would be placed in the bath for 1hr to add .2% carbon. totally different than dropping a hot part in a bath of oil.

also, the old timers weren't adding carbon by dropping steel parts into oil, the oil just controls the cooling rate. The time at temperature in the oil isn't long enough to add carbon to any significant depth. Unless of course the whole bucket of oil is in the oven at 1500 degrees for a few hours.

Liquid pack carburizing uses a molten salt bath. An example is Sodium Cynide, which would be in a bath at 1600 degF. to achieve a .001" deep case, a part made of 1020 steel would be placed in the bath for 1hr to add .2% carbon. totally different than dropping a hot part in a bath of oil.

owen said:The time at temperature in the oil isn't long enough to add carbon to any significant depth.

That's what I said in my first post but carbon can diffuse into the brass enough to discolor it because the brass is red when it's dropped in the oil.

owen said:also, the old timers weren't adding carbon by dropping steel parts into oil, the oil just controls the cooling rate.

When I was in welding school in the mid '80s, we heated a mild steel rod to cherry red and then wiped it with a rag soaked in used engine oil. We repeated this process until the whole rod was a deep black at room temperature. We then cut the rod in half and polished the cross section to show the thin, iron carbide (Fe3C) shell. This method produces a hard finish on the surface that is not just a coating. The carbon chemically bonds to the surface of the steel. The depth of the Fe3C layer is dependent on carbon concentration in the part, temperature and time so obviously, a quick dunk of cherry red brass in dirty oil won't achieve much other than softening the brass and changing the color.

This kind of thread makes me want to conduct an experiment of my own.

Remo223

member

the problem is that the time isn't long enough to introduce carbon.

also, the old timers weren't adding carbon by dropping steel parts into oil, the oil just controls the cooling rate. The time at temperature in the oil isn't long enough to add carbon to any significant depth. Unless of course the whole bucket of oil is in the oven at 1500 degrees for a few hours.

I thought so too, that's why in post 39 I asked if he was pre heating the oil.

- Status

-

Not open for further replies.

Similar threads

- Replies

- 11

- Views

- 2K

- Replies

- 7

- Views

- 768

- Replies

- 2

- Views

- 377

- Replies

- 91

- Views

- 21K

- Replies

- 2

- Views

- 627