OKAY! Did a test with Universal today.

I set up my Aquarium pump and used rubber bands to secure it against the hopper. As I was setting up my digital scale it dawned on me the vibration might affect the digital scale. I also thought about how vibration might affect the integrity of the individual balls and flakes of the powders I use and off came the vibe unit.

Scrubbed vibe motor idea.

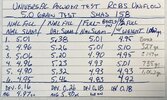

I then did 4 tests: See index card below

1. I filled the hopper the way I would normally fill my powder measure if I were loading 100 or so 9mm rounds. Powder just over top of the baffle. A single whack of the handle up and down, just like I always do normally. Deviation .16 grains

2. Hopper filled the same as above only whacking the handle twice at the bottom of the throw and twice at the top of the throw. THIS definitely compacted the powder, but I still got a deviation of .26 grains in 6 throws.

3 Filled hopper to the top with the baffle in. Made a heckuva mess when whacking the lever down then up. Put cap back on.

. In 6 throws I got a deviation of .18 grains.

4. This one was interesting

@Tilos I had to find a way to put consistent pressure on the head of the powder column. I chose a medicine bottle with five 147 grain bullets in it. Total Weight 1,062grains. I removed the baffle and filled hopper half way. I got a deviation of .18 grains.

SMAS (small micro adj. screw) setting 158 for all testing.

How I would normally fill hopper to load 100 rounds. Used this for test 1 & 2

Full hopper for test 3 with baffle in.

Weighted powder column test 4.

Same set up as photo above

My decision:

Eventually I think I am going to take the advice of

@mm93 and but a Harrell's Precision measure. It’ll be a few months, but I will get one. Fixed income and several hobbies take strategic budgeting.

Until then I am going to convert my use of flake powders to ball powders for many of my loads.

Most of my loads using flake powder are more like plinking loads and I don’t load near maximum pressures.

NOTE: I did a quick test with HP-38 filling the hopper as shown in Test 1 and setting the SMAS at 155 which should give me ~5.0 grains. The deviation in 6 throws (highest to lowest measurement) was

.09 grains. 4.90-4.99 grains

I can live with that. It was just a quick test at the end of what I was willing to do today. Back hurts.

So, there you have it. The bottom line is Flake Powders just do not meter as well as Ball Powders in any of

my configurations with an RCBS Uniflow powder measure.