All screws fire blued and timed/qualified, that's ALL screws even the backstrap and trigger guard

Howdy

It's interesting you mentioned that.

I must admit that before Standard Mfg Co came out with their version of the SAA I had never heard off screws being timed/qualified.

Did not even know what it meant, I had to look it up.

As I understand it, this means that when the screws are torqued down the slots are all lined up the same way. Horizontal in this case.

This is not a feature on Colts.

A pair of 2nd Gen Colts that shipped sometime in the 1970s, as I recall. Notice how the screw slots are oriented randomly.

Another pair of 2nd Gen Colts. The top one shipped some time in the 1970s, the bottom one about 1968. Notice how the orientation of the screw slots is random.

A 1st Gen Bisley model from about 1908 or so. I suspect the fire blue of the screws is not original, but the rest of the finish is. Again, the orientation of the screw slots is random.

This 1st Gen Bisley also shipped around 1908 or so. The screw slots all point more or less the same direction, but they are not horizontal. I suspect this is just chance that they line up more or less the same.

A Colt New Frontier. Random orientation of the screw slots.

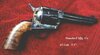

A Colt Richards Conversion. Random orientation of the screw slots.

So I guess having all the screw slots on the Standard Mfg Co SAA replica line up the same is a nice touch, but as far as I know, it is not a feature that is authentic to a Colt.

Having some experience with CNC machining, I suspect making this happen is fairly simple to do on a CNC miller. The tap has to bite into the steel at the exact same orientation each time, so the screws will all line up the same. The traditional way to thread tapped holes is the tap comes down and enters the metal in a random orientation. Where ever the tap happens to bite the steel as it is lowered to the metal, is where the thread starts, so the orientation of the screw slots winds up being random. I suppose each screw could be made extra long, then marked and removed so slots could be cut so they will be horizontal when torqued down, but I have never seen that done on any production revolver. Slots just wind up oriented randomly.