Jeremy2171

Member

CMP says 180gr commercial ammo and below is safe... greater than that "may" not "will" cause increased wear.I’d rely on CMP to answer about op rods, gas plugs, and non m2 ball suitability. They are the largest and best trained gunsmiths on the US Rifle Caliber 30 M1 around today. All of the armorers etc from Springfield Armory are long since gone, seeing as how the Armory was closed 52 years ago. If CMP gives it a go ahead believe it, if no go believe that. Nuff said

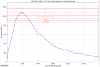

Actual testing shows commercial ammo operates at similar pressure as milsurp and operates the action at similar velocity so no danger... including 220grn ammo.