hubel458

Member

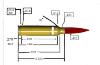

Here is picture of a brake on 12ga FH with real hot loaded

hollowbase lead slug, brake needed more clearance

for the expanding slug.

Here is the before and after of 375 HE cases

necked, 2 on left, and then formed in hydro die... Ed

Here is pic of 416 HSM second from left we are experimenting

with, going to see if we can make the ultimate 416 ELR case.

Can be 3.60" to 4.00" long, a long one pictured.

Holds over 280 gr ball powder under bullet. The

3.6" case can hold about 250gr under bullet.. In picture,

1st case is 416 HE, 2nd 416 HSM, 3rd 375 He, 4th 378 WEA.

416 HSM will get 400gr to 4100 plus without needing BMG action,

470 gr 3800 plus , it may be the ultimate target, singleshot 416..

Case will work in fat bolt actions, with heavy enough barrel

to have good, milder, barrel harmonics and be under 50 lbs.

A lot of the 2 mile type shoots are adopting 50lb limit.

Here is picture of the 416 HSM fireformed once,

next to bmg case we make it from and as we

improve wildcatting process next few weeks

some specs may make small changes, now from

base to shoulder is 3.45", case 3.97" long. Ed..

Manson has 416 HE and 408 HE prints, as well as 375 HE

He can also make you a resize die reamer from that info.

We got 700 cases in 416 and one more pass if 408s wanted, ,

Going to do lot more cases for these 2 sizes,

PM or email. ph 989-644-5228..

Here are final specs for 416 HE.

Length 3.32", belt diameter ,655", base dia .635" ,

length base to to shoulder 2.860" , 30 deg shoulder.Ed

hollowbase lead slug, brake needed more clearance

for the expanding slug.

Here is the before and after of 375 HE cases

necked, 2 on left, and then formed in hydro die... Ed

Here is pic of 416 HSM second from left we are experimenting

with, going to see if we can make the ultimate 416 ELR case.

Can be 3.60" to 4.00" long, a long one pictured.

Holds over 280 gr ball powder under bullet. The

3.6" case can hold about 250gr under bullet.. In picture,

1st case is 416 HE, 2nd 416 HSM, 3rd 375 He, 4th 378 WEA.

416 HSM will get 400gr to 4100 plus without needing BMG action,

470 gr 3800 plus , it may be the ultimate target, singleshot 416..

Case will work in fat bolt actions, with heavy enough barrel

to have good, milder, barrel harmonics and be under 50 lbs.

A lot of the 2 mile type shoots are adopting 50lb limit.

Here is picture of the 416 HSM fireformed once,

next to bmg case we make it from and as we

improve wildcatting process next few weeks

some specs may make small changes, now from

base to shoulder is 3.45", case 3.97" long. Ed..

Manson has 416 HE and 408 HE prints, as well as 375 HE

He can also make you a resize die reamer from that info.

We got 700 cases in 416 and one more pass if 408s wanted, ,

Going to do lot more cases for these 2 sizes,

PM or email. ph 989-644-5228..

Here are final specs for 416 HE.

Length 3.32", belt diameter ,655", base dia .635" ,

length base to to shoulder 2.860" , 30 deg shoulder.Ed