Buck13

Member

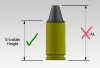

New to reloading 9 mm. I have a Dan Wesson PM9 and a 9 mm carbine, while my wife has a CZ P-01. With truncated cone bullets, either Hornady HAP or Bayou coated lead, the DW seems to plunk with about 0.05" longer bullets than either of the other guns, and with coated SWCs it can go a bit longer than with the HAPs while the others require those seated with the shoulder practically at the case mouth.

I don't mind making up some ammo specific to the DW if it pays off in accuracy. For the TCs, is it typically that seating closer or farther from the throat works out better? I've only shot one batch of the HAPs in the DW so far, with 4.3 grains of HP38, seated about 0.03" back from their longest COAL and they were maybe slightly better off a rest than S&B factory RN FMJ, but nothing dramatic. Reduced recoil was nice, though.

I'll play with the SWCs some in the DW but forget about them in the other guns. Not worth the aggravation! Again, any predictions about spacing for them?

I don't mind making up some ammo specific to the DW if it pays off in accuracy. For the TCs, is it typically that seating closer or farther from the throat works out better? I've only shot one batch of the HAPs in the DW so far, with 4.3 grains of HP38, seated about 0.03" back from their longest COAL and they were maybe slightly better off a rest than S&B factory RN FMJ, but nothing dramatic. Reduced recoil was nice, though.

I'll play with the SWCs some in the DW but forget about them in the other guns. Not worth the aggravation! Again, any predictions about spacing for them?