You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BulletMatch, a Catalog of Cast Bullets

- Thread starter Bazoo

- Start date

Thanks for sharing your work!We created a lead alloy calculator https://bulletmatch.com/pages/lead-alloy-calculator to help the casting community figure all of that scrap lead that’s been setting around.

One quick suggestion. I was playing with the alloy calculator. It appears to only allow weight value entries in increments of 0.5 lbs. The number of bullets is calculated based on actual weights entered, but the alloy content only updates in increments of 0.5 lbs. This makes it tricky when trying to calculate small batches. Should allow small value entries to get more precise alloy calculations.

Bazoo

Member

Thanks! I went and checked it, like you said. I had not noticed that.Thanks for sharing your work!

One quick suggestion. I was playing with the alloy calculator. It appears to only allow weight value entries in increments of 0.5 lbs. The number of bullets is calculated based on actual weights entered, but the alloy content only updates in increments of 0.5 lbs. This makes it tricky when trying to calculate small batches. Should allow small value entries to get more precise alloy calculations.

Bazoo

Member

I've got another 30+ samples in the other day, and updated my list.

Here's my spreadsheet for everyone which shows the samples I have on hand. Bullet Samples

Here's my spreadsheet for everyone which shows the samples I have on hand. Bullet Samples

Bazoo

Member

Excellent samples.

Bazoo

Member

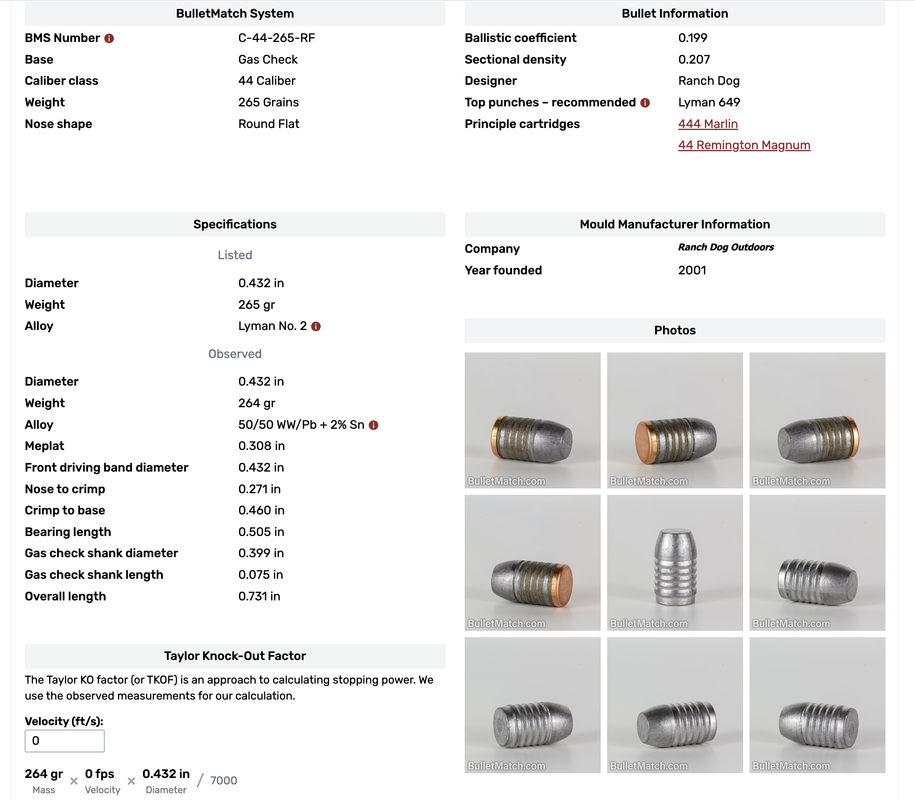

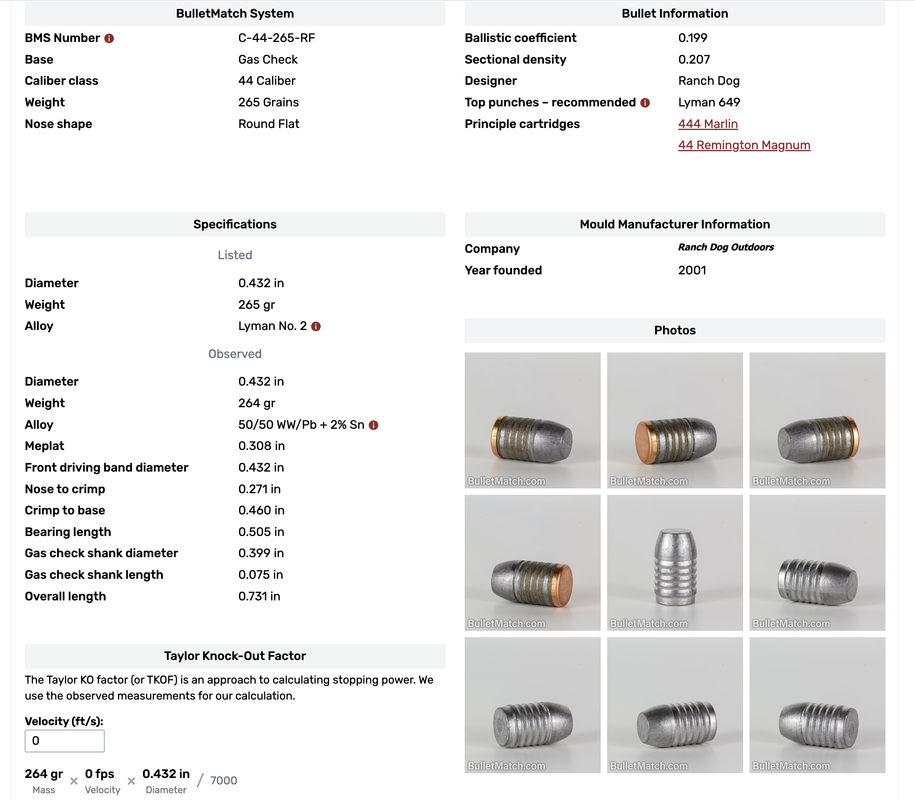

My current favorite 44 Magnum bullet is the Ranch Dog 432-265-RF. I use it in my Winchester 1892 in 44 Magnum, mostly over a full dose of W296, and of course I use it in my Ruger Blackhawk in 44 Special with Bullseye or Unique.

Bazoo

Member

Bazoo

Member

Thanks for sharing your work!

One quick suggestion. I was playing with the alloy calculator. It appears to only allow weight value entries in increments of 0.5 lbs. The number of bullets is calculated based on actual weights entered, but the alloy content only updates in increments of 0.5 lbs. This makes it tricky when trying to calculate small batches. Should allow small value entries to get more precise alloy calculations.

I finally got with my buddy and he got it straightened out. It figures down to a smaller precision now.Thanks! I went and checked it, like you said. I had not noticed that.

Bazoo

Member

Bazoo

Member

Hooda Thunkit

Member

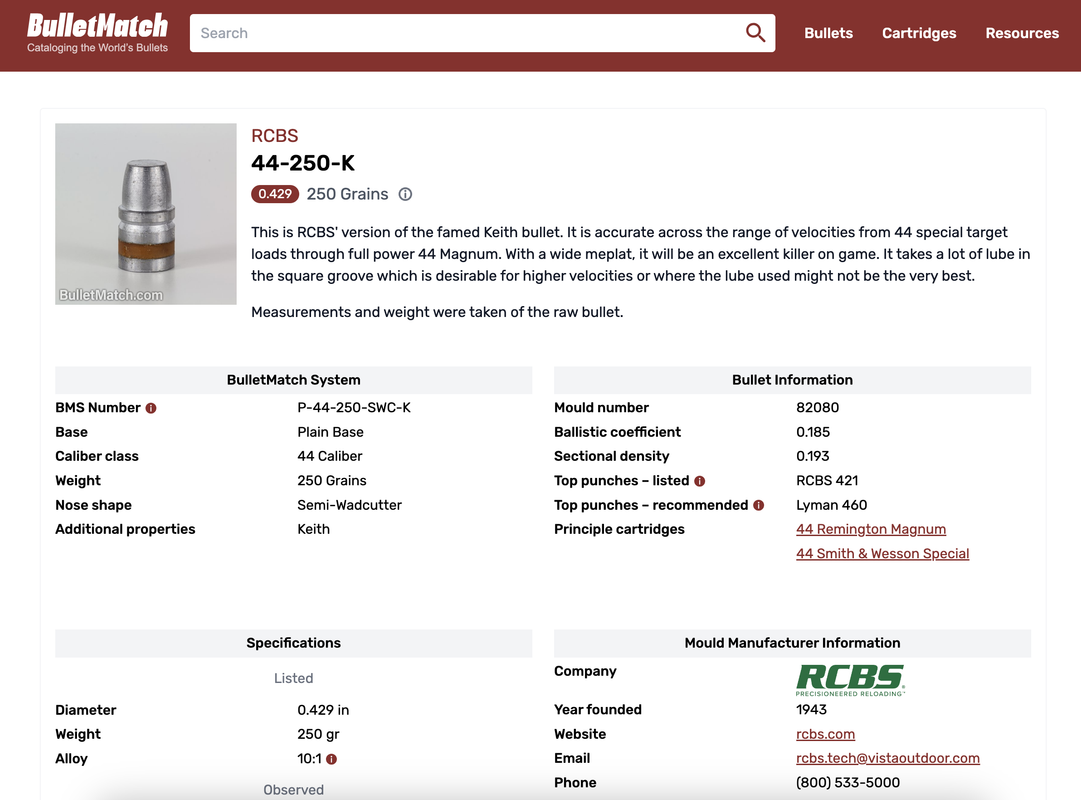

And it's just a really good looking bullet!Been working with my RCBS 44-250-K for a while. I'm about to do some load development in my Winchester 1892 in 44 Special brass.

Bazoo

Member

I like it. It’s always interesting to me to see all the different slight variations on the Keith bullet.And it's just a really good looking bullet!

Bazoo

Member

Bazoo

Member

What's listed is not always what you get. The bullet I measured was cast from range scrap and measured .311. I like .310 for my 30-30 as well.I like my 30-30 at .310. If the mix is already linotype at .309 probably can't get to .310

Bazoo

Member

Anyone have the 30-150-SWC and can attest if this is the norm for that bullet?

Bazoo

Member

I got some exciting samples in: Lyman’s 429215 and 429244. Some extras were included for me to try in my guns! I’ve been wanting to try them both in my Blackhawk and Winchester.

Last edited:

Bazoo

Member

I have been working hard on bullet samples the last few weeks and I've got another 40 sets of bullet pictures, which means those bullets are about to be completed. There's a lot of good classics in this batch.

Bazoo

Member

Anyone wanna guess what we have here?

AJC1

Member

I didn't jump in right away as I figured your project would be swamped with samples. Are you back logged or are you all caught up and need some...I have been working hard on bullet samples the last few weeks and I've got another 40 sets of bullet pictures, which means those bullets are about to be completed. There's a lot of good classics in this batch.

Bazoo

Member

Howdy, thanks for the interest. Right now I'm close to caught up except for the new moulds.I didn't jump in right away as I figured your project would be swamped with samples. Are you back logged or are you all caught up and need some...

I have about 50, which are the last of my good samples, that will be finished soon, all with pictures taken, I just have to finalize them and make them show on the site.

I have a handful of extra long bullets that I'm waiting on until I get enough to warrant changing my photo setup for those.

Then the only thing left is about 500 commercial samples (I've already started whittling away at them), but they go quickly because I don't have to do much research on them.

I spend quite a bit of time researching bullets to make sure I get the top punches, suggested alloys, and other details correct for the home cast bullets. Generally with commercial samples, there is no top punch, the alloy used is the same for all the samples sent to me, and they are packaged in a way that makes the process smoother.

AJC1

Member

My samples would be mostly noe, they are super about having that data on their site....Howdy, thanks for the interest. Right now I'm close to caught up except for the new moulds.

I have about 50, which are the last of my good samples, that will be finished soon, all with pictures taken, I just have to finalize them and make them show on the site.

I have a handful of extra long bullets that I'm waiting on until I get enough to warrant changing my photo setup for those.

Then the only thing left is about 500 commercial samples (I've already started whittling away at them), but they go quickly because I don't have to do much research on them.

I spend quite a bit of time researching bullets to make sure I get the top punches, suggested alloys, and other details correct for the home cast bullets. Generally with commercial samples, there is no top punch, the alloy used is the same for all the samples sent to me, and they are packaged in a way that makes the process smoother.

Bazoo

Member

I'd love to have them, whenever you could get them together.My samples would be mostly noe, they are super about having that data on their site....

Bazoo

Member

Bazoo

Member

One of the things about BulletMatch that I've been asked is "Do you measure the bullets or use the dimensional drawings that manufacturers provide?" I always measure and weigh each bullet myself, and record that information. The reason being is that often times the actual bullet will be somewhat different, either due to matching tolerance or alloy shrinkage.My samples would be mostly noe, they are super about having that data on their site....

Anytime I have NOE bullets, I reference their sight for some details, particularly their Name Mapping Page, so I can get that correct. It was confusing to me to start with, so I felt adding it to the bullets on BulletMatch would be beneficial to others as well.

Similar threads

- Replies

- 22

- Views

- 841

- Replies

- 4

- Views

- 1K