You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

308 Twist? 1:12 or 1:10

- Thread starter Olympus

- Start date

- Status

-

Not open for further replies.

tark

Member

Thanks, Lysander. My education has been furthered.

ColoradoShooter77

Member

My Remmy 700 SPS has a 1:10 twist and I'm glad. I like to shoot the heavier 168 and 175 grain bullets. This twist also handles the 150 grain bullets just fine as well.

Nature Boy

Member

- Joined

- Apr 21, 2015

- Messages

- 8,291

lobo9er

Member

I have been reading about a bunch of different 308 rifles and 1-10 is the twist rate most manufacturers go with. Kimber seems to be the only company that seems to use 1-12 almost exclusively, at least of the guns I have been reading about. If I remember right I thought I read that accuracy doesn't really change until 4-600 yards? But I maybe way off and spreading bad information, so theres my disclaimer.

lysanderxiii

Member

AD A205633 - Aerodynamics Characteristics of 7.62 Match BulletsI guess I need to tell my FN SPR with it's 1:12 twist that it can't shoot 168-180 grain bullets. On second thought, I won't tell it. It might hurt its confidence.

3. Gyroscopic Stability

The variation of launch gyroscopic stability factor, SG with launch Mach number at standard atmospheric conditions, is shown for the three 7.62mm match bullets in Figures 27 through 29. The stability factors for 10 inch twist and 12 inch twist of rifling are illustrated. For a launch Mach number of 2.3 (muzzle velocity approximately 2570 feet/second), the M118 bullet from a 12 inch twist barrel has a gyroscopic stability factor of 1.4; the stability factor of the 190 grain Sierra Matchking at the same muzzle velocity and twist rate is 1.3. The corresponding value of SG for the 168 grain Sierra International bullet at the same conditions is 1.65. Thus, all the above 7.62mm match bullets are gyroscopically stable when fired from a 12 inch twist barrel at muzzle velocities greater than 2500 feet/second. However, for the M118 bullet, and especially for the 190 grain Sierra Matchking, there is no margin of safety for cold weather (high air density) atmospheric conditions, if a 12 inch twist is selected.

A launch gyroscopic stability factor between 1.5 and 2.0 is usually specified, to insure ample safety margin under worst case conditions. Thus for the 7.62mm NATO cartridge. The 12 inch twist rate is an excellent choice for the 168 grain Sierra International (M852) bullet, and a 10 inch twist barrel should be selected for the M118 or 190 grain Sierra Matchking bullets.

I think we stated that 1-10 or 1-12 are fine for the heavy bullets unless you are in extreme conditions.

Just for reference a M193 55 grain bullet at 3300 fps from a 1-12 twist has an SG of 1.3-1.4.

Last edited:

lysanderxiii

Member

If they are over stabilized, yes.lysander, are you saying howitzer projectiles maintain their high angle line of fire axis all the way to long range targets and strike base first on level ground?

With long range artillery, fired at high angles of departure, it is very important to not to have them over stabilized, as landing base first will cause failure of the fuze, either base fuzed or point fuzed, to detonate the bursting charge. Long range projectiles need to nose-over at apogee.

If they are over stabilized, yes.

With long range artillery, fired at high angles of departure, it is very important to not to have them over stabilized, as landing base first will cause failure of the fuze, either base fuzed or point fuzed, to detonate the bursting charge. Long range projectiles need to nose-over at apogee.

This is all very true for artillery. But I have never heard of a twist/bullet combination you could reasonably see in the field that does it with small arms. For example, I don't think 1:7 twist on M193 is enough to exhibit over-stabilization. I know fast-twist 1:14 .458 barrels don't choke on light projectiles designed for 1:40 barrels.

Over-stabilization seems like a boogeyman to me.

lysanderxiii

Member

I believe I said that...This is all very true for artillery. But I have never heard of a twist/bullet combination you could reasonably see in the field that does it with small arms. For example, I don't think 1:7 twist on M193 is enough to exhibit over-stabilization. I know fast-twist 1:14 .458 barrels don't choke on light projectiles designed for 1:40 barrels.

Over-stabilization seems like a boogeyman to me.

It is normally only a problem at high angles of departure (howitzers and the like). You can calculate the rpm necessary for this, and for a .75" long .224" diameter bullet, 1-7 twist will not do it. And, even if you did "over-stabilize" a rifle bullet, the angles of departure are usually low enough that it will not cause problems.

Went to a week long mechanics training class with a guy who shot benchrest. We talked quit a bit about gun related stuff. His thought on twist was when there was any doubt go with a faster twist. In his opinion , in MOST cases, over stabilization was not a big issue. The reason being that bullet length also influences the twist needed. The ogive , type of tip, shape of the base or boat tail all can make a difference. I don't remember the specifics, but he had a 6mm ppc barreled for the minimum twist for a very short bullet. The bullet became unavailable and nothing else worked good enough for competition. Pooof about 2000 dollars gone.

stubbicatt

Member

Lysander's posts make sense to me, and help put into perspective the Schuetzen adage that the old timers use, namely that you want a bullet/twist rate right on the edge of instability or your bullet will go through the target "nose high" if it is over stabilized. But then the trajectories of those cast bullets launched between 1300 and 1400 fps are more like an artillery shell than the comparatively flat trajectory of a 308. Also gets me thinking of the CG of the short nosed, Pope style, bullet vis muzzle deflection, as the CG will likely be more nose forward than a higher BC spitzer. Probably less precession with this bullet design, also explains the no need for windage adjustments from 50 to 200 meters I have observed as I am not countering those forces due to bullet/twist rate/velocity balance. Also helps explain the better performance of a 204 grain bullet over a 165 grainer at a 15 pitch twist rate.

Thanks Lysander.

(Sorry if this is off topic, but I learned a lot. Wanted to say thanks.) Thanks for post #24

Thanks Lysander.

(Sorry if this is off topic, but I learned a lot. Wanted to say thanks.) Thanks for post #24

Last edited:

greenmtnguy

Member

I'd also vote for the 1:10 twist rate for the wider range of projectile weights supported. I've seen accurate rifles with both twist rates for mid-weight bullets.

lysanderxiii

Member

The bullet weight is relatively unimportant in regards to stability. It is largely governed by length and to a lesser extent by nose shape.The reason being that bullet length also influences the twist needed. The ogive , type of tip, shape of the base or boat tail all can make a difference.

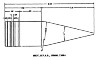

This is the formula for static stability (SG):

Ix and Iy are the moments of inertia about the X an Y axis.

w is the spin

ro is the density of the bullet

Cma is the overturning moment coefficient

d is the diameter

Most "stability calculators" use constants for Ix, Iy and Cma, so they estimate stability based on spin (twist and Vm), sectional density (weight and diameter) and diameter. Better ones use the ballistic coefficient to refine the Cma.

lysanderxiii

Member

Cma is density related, it has all the aerodynamic factors in it.

tark

Member

Wow. I think we have a bunch of Doctorial degrees in Thermodynamics and Ballistics weighing in, here!

Wish I was one of them !!!!

!!!!

Wish I was one of them

You will be in better shape when when lead bullets are bannedWell I decided up go with the AAC model with the 1:10 twist

Vern Humphrey

Member

There are two trends in ammunition to take into account. One is bullets with no lead -- for a given weight, these bullets tend to be longer than conventional lead core bullets. The other is very low drag bullets, which also tend to be longer than conventional bullets.

It would seem, then that a faster twist is indicated for the ammunition of the future.

It would seem, then that a faster twist is indicated for the ammunition of the future.

lysanderxiii

Member

A few things...There are two trends in ammunition to take into account. One is bullets with no lead -- for a given weight, these bullets tend to be longer than conventional lead core bullets. The other is very low drag bullets, which also tend to be longer than conventional bullets.

It would seem, then that a faster twist is indicated for the ammunition of the future.

The lead slug in a 168 gr SMK and the 174 gr M72 Match Ball do not completely fill the copper jacket. A solid copper projectile made to the same outside dimensions as these two projectiles would actually weigh more than their lead/copper bretheren, 176 gr and 180 gr respectively. This is true of most match bullets.

The 190 gr SMK would grow a phenomenal 0.017" in length (the thickness of four sheets of 20 lb bond paper), assuming the outside dimensions: ogive, boat-tail and secant location, remain the same. This would not make any appreciable difference in the twist required to stabilize it.

The SG factor a 190 gr SMK shape at 2500 fps for a lead/copper projectile is 1.46 in a 1-12 twist, if you add a .017" cylindrical section to add volume to bring the weight of an all copper 190 gr SMK shape, the SG drops a whopping 0.05 to 1.41. Still well stabilized with a 1-12 twist.

The trend that is causing longer bullets is not so much lighter densities, but larger nose ogives with larger secant offsets (VLD projectiles). The shift to all-copper doesn't change bullet weight that much. This trend is also causing the nose of the bullet to protrude further beyond the case mouth, with associated OAL problems in magazines.

Last edited:

lysanderxiii

Member

Vern Humphrey

Member

Both factors are at play -- compare a simple cup-and-core bullet, with a Barnes Tipped Triple Shock, for example.The trend that is causing longer bullets is not so much lighter densities, but larger nose ogives with larger secant offsets (VLD projectiles). The shift to all-copper doesn't change bullet weight that much. This trend is also causing the nose of the bullet to protrude further beyond the case mouth, with associated OAL problems in magazines.

- Status

-

Not open for further replies.

Similar threads

- Replies

- 6

- Views

- 536