Echocrewchief

Member

Preface: New to the forums and I've done a ton of reading here and would like to start by saying thank you to all of the posters. I've learned A LOT.

I'm new to reloading and started with 9mm and have been rather successful (non-competitive target) with the cartridges that I've made so far. Recently the other dies that I've ordered have come in - specifically the 45 auto dies. Made up a bunch of rounds and had some issues at the range.

None of them failed to fire, but there were a number of fail to feed - about 2 in 10. I did not experience any stove pipes and just about every round that failed to feed, I chambered it as the first round, and it fed and fired. NOTE - I did have a box of Winchester White Box and all of the rounds fed and fired as expected.

Equipment: Hornady LnL single stage press, with Hornady dies.

Specifics: I kept 2 of each type of round that failed to feed for further inspection back at the bench.

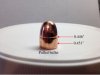

1. Xtreme RN-CP 230gr. / COL 1.244" / Crimp .472" / 4.4gr Titegroup

2. Xtreme RN-CP 230gr. / COL 1.252" / Crimp .472" / 4.4gr Titegroup

3. HSM RN-CP 230gr. / COL 1.241" / Crimp .472" / 4.4gr Titegroup

4. HSM RN-CP 230gr. / COL 1.228" / Crimp .472" / 4.4gr Titegroup

5. Hornady HP-FMJ XTP 185gr. / COL 1.211" / Crimp .472" / 5.8gr Titegroup

6. Hornady HP-FMJ XTP 185gr. / COL 1.210" / Crimp .473" / 5.8gr Titegroup

Case: RWS - brand new (didn't know about SPP and LPP at the time of purchase - no wonder it was a deal)

Primer: CCI SPP

Weapon: Ruger SR 1911

Mags: 2 that came with the gun and 2 that I purchased and used without issue with factory ammo

Outside Air Temp: 31F

*No chronograph at the time, but wife just bought one for me so I'll have more data later.

Measuring the remaining rounds I didn't shoot...

Average COL for the HSM - 1.247"

Average COL for the Xtreme - 1.253"

Average COL for the XTP - 1.245"

The only other thing to note was some of the fired brass (don't know from which load) had some staining on it - like powder burn on the side. My research into this seemed to indicate a possible light load and the case didn't seal properly in the chamber.

So the question, after this wall of text, is... are the COL at issue here? Did I seat some bullets too far? I also understand that some powders are temperature sensitive, but haven't read that Titegroup is one of them.

Thank you in advance for any replies!

I'm new to reloading and started with 9mm and have been rather successful (non-competitive target) with the cartridges that I've made so far. Recently the other dies that I've ordered have come in - specifically the 45 auto dies. Made up a bunch of rounds and had some issues at the range.

None of them failed to fire, but there were a number of fail to feed - about 2 in 10. I did not experience any stove pipes and just about every round that failed to feed, I chambered it as the first round, and it fed and fired. NOTE - I did have a box of Winchester White Box and all of the rounds fed and fired as expected.

Equipment: Hornady LnL single stage press, with Hornady dies.

Specifics: I kept 2 of each type of round that failed to feed for further inspection back at the bench.

1. Xtreme RN-CP 230gr. / COL 1.244" / Crimp .472" / 4.4gr Titegroup

2. Xtreme RN-CP 230gr. / COL 1.252" / Crimp .472" / 4.4gr Titegroup

3. HSM RN-CP 230gr. / COL 1.241" / Crimp .472" / 4.4gr Titegroup

4. HSM RN-CP 230gr. / COL 1.228" / Crimp .472" / 4.4gr Titegroup

5. Hornady HP-FMJ XTP 185gr. / COL 1.211" / Crimp .472" / 5.8gr Titegroup

6. Hornady HP-FMJ XTP 185gr. / COL 1.210" / Crimp .473" / 5.8gr Titegroup

Case: RWS - brand new (didn't know about SPP and LPP at the time of purchase - no wonder it was a deal)

Primer: CCI SPP

Weapon: Ruger SR 1911

Mags: 2 that came with the gun and 2 that I purchased and used without issue with factory ammo

Outside Air Temp: 31F

*No chronograph at the time, but wife just bought one for me so I'll have more data later.

Measuring the remaining rounds I didn't shoot...

Average COL for the HSM - 1.247"

Average COL for the Xtreme - 1.253"

Average COL for the XTP - 1.245"

The only other thing to note was some of the fired brass (don't know from which load) had some staining on it - like powder burn on the side. My research into this seemed to indicate a possible light load and the case didn't seal properly in the chamber.

So the question, after this wall of text, is... are the COL at issue here? Did I seat some bullets too far? I also understand that some powders are temperature sensitive, but haven't read that Titegroup is one of them.

Thank you in advance for any replies!