Lube your 303 Brit before firing. After firing, bump the shoulder back 0.003", and lube them again before firing.

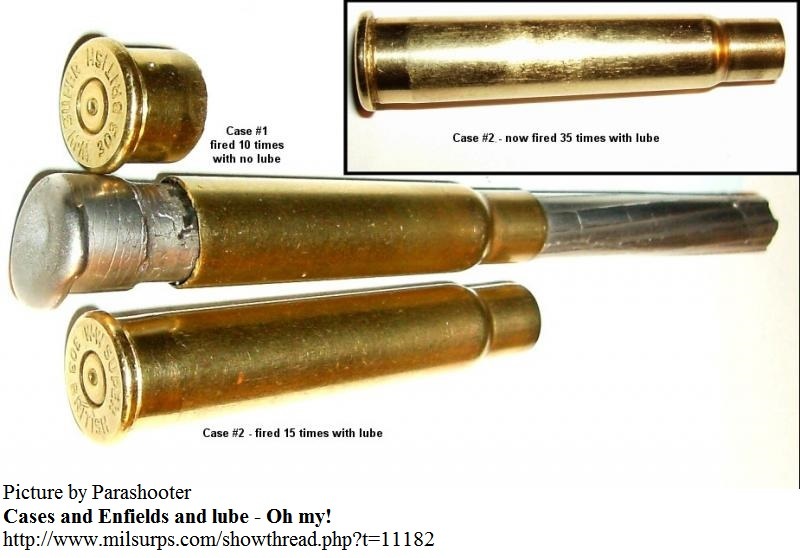

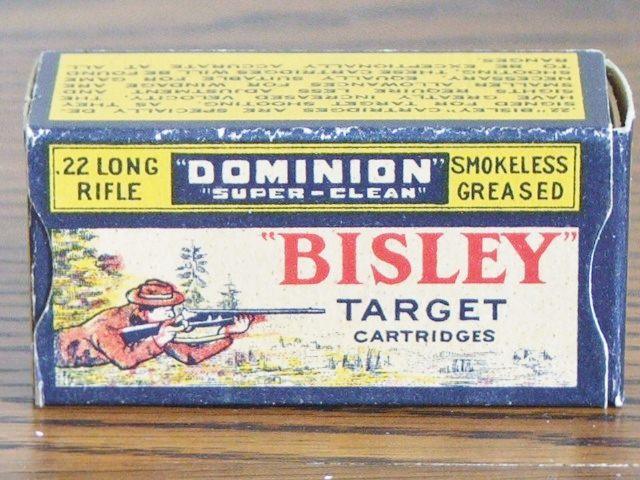

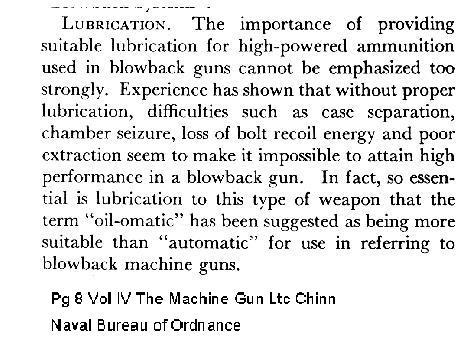

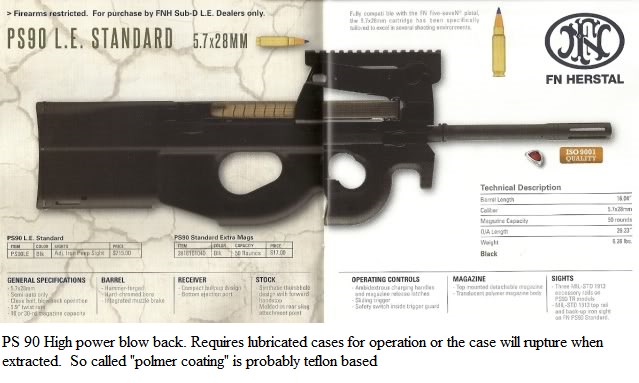

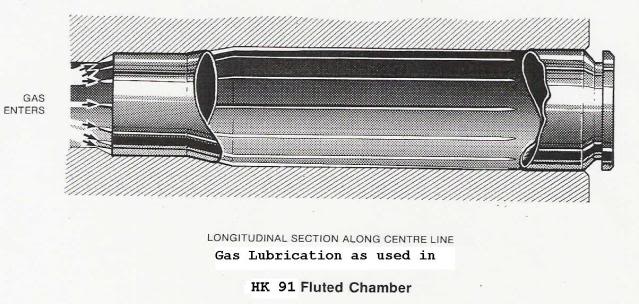

The Brits had cupro nickle bullets which jacket fouled something awful. However, greasing the bullets prevented jacket fouling. Greasing a bullet will end up with grease in the chamber, which prevents case head separations. Such as:

Greased bullets and cases were very prevalent with SMLE's.

Chronicle Newspaper, 13 Feb 1930 Adelaide Australia

Opinion is so divided on the question of the benefits of using greased bullets that riflemen would be well advised to give the practice a thorough try-out to ...

trove.nla.gov.au

Rifle Shooting

GREASED BULLETS

Opinion is so divided on the question of the benefits of using greased, bullets that riflemen would be well advised to give the practice a thorough try-out to ascertain if their present method of shooting is giving the best results. This advice applies to those using a lot of lubricant, those using a little, and those who do not use any. There are prominent riflemen who pile the lubricant on the bullet and get good scores; there are others who have been equally as free with the grease and have got very bad scores; and naturally the two parties hold very different opinions on the subject. The greasing of bullets was introduced in an attempt to prevent the nickel of the bullet adhering to the surface of the inside of the barrel when firing was being carried out. The theory that a lubricant would prevent the two metals “sticking” appears quite in order, but this prevention had to be carried out without any loss of the rifle's accuracy. It was here that the trouble occurred as it was found that as soon as the heat of the barrel turned the grease to oil, which worked into the chamber of the barrel, the bullets began to fly high, as is the case when water gets into the chamber. * The riflemen who had scores spoilt in this manner immediately discarded the use of the lubricant, preferring to chance the nickel trouble as the lesser of the two evils. But, seeing that other men used lots of grease and continued to get good scores, the question arose as to whether the state of the rifling of the barrel should not be taken into consideration with the grease question. Men with new Enfield barrels which have sharp lands, bandied the greased bullets better than those with Metford barrels, which have shallow round lands. This implies that worn barrels do not handle greased bullets as well as the new. One good shot recently was having a run of poor scores. His rifle picked up nickel, so he always used greased bullets. He decided to discontinue the use of the grease, and his scores immediately improved several points. Two other big shots had the same experience. It is possible that had they experimented with reduced amounts of lubricant they might have discovered that they could use a certain amount and get good scores, and at the same time keep the nickel down. There can be little doubt that less lubricant could be used with advantage in the summer, owing to it melting more quickly than in the winter. Rifle men should not only experiment with the quantity to be used but also with the kind, there being several different brands in use.

*

note: the Lee Enfield action is very flexible and changes in breech friction create a point of impact change)