DJ,Howdy

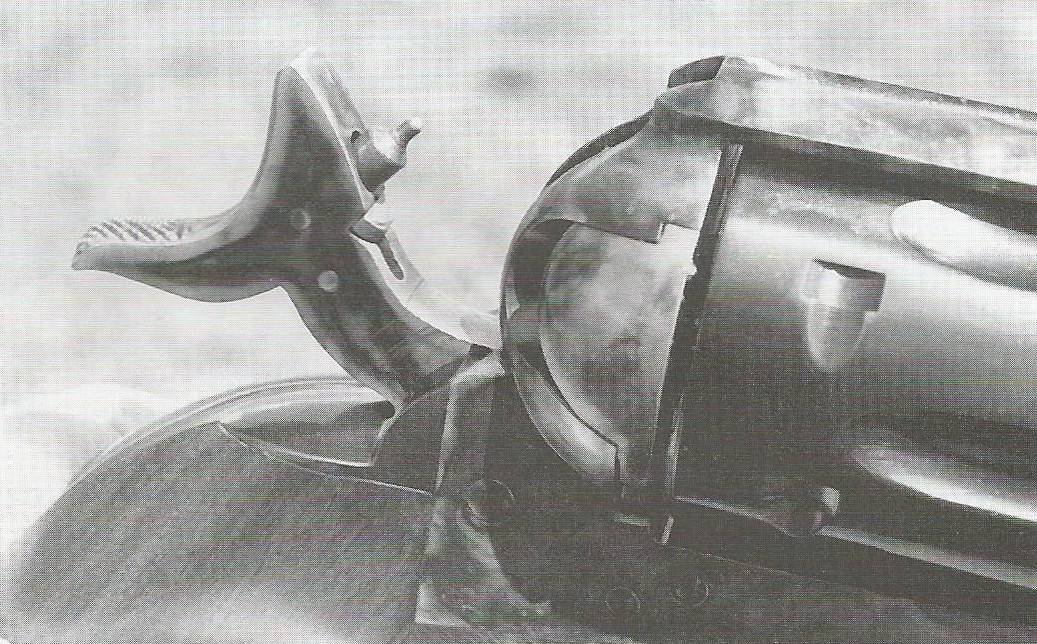

Over the years there have been various changes regarding hammer blocks in Smith and Wesson double action revolvers with side swinging cylinders...

In 1944 (not 1945) a sailor was killed when a Victory Model Smith and Wesson fell to the deck of a warship. I have heard several versions of this story, but the most believable one I heard is that a pilot was climbing out of the cockpit of his plane on an aircraft carrier, and his revolver fell to the deck. If this version is true, the revolver would have fallen quite a distance as he climbed off the wing of his plane, and when it landed on its hammer it discharged, killing the sailor. An investigation found that hardened cosmoline had probably prevented the spring steel hammer block from moving forward to the 'safe' position, and the force had been enough to break enough parts and the revolver discharged. …

Once again a great photo-journalistic explanation of the topic! The images explain what the words suggest.

The Navy story with which I am familiar is the revolver dropped at least one deck to land on the steel deck and discharge. But the fact that the hardened cosmoline had rendered the safety inactive was downplayed. The US Government can never be seen to be wrong, no matter what the policy was that caused the error. Regardless, the new safety was designed and adopted and the contract was saved!

I often wonder what the reaction was to the new “Government mandated safety”? Did all the minions boycott buying S&W revolvers because of it? Or, was it the great non-issue, like the internal storage lock?

Kevin