Michael Tinker Pearce

Member

- Joined

- Oct 23, 2016

- Messages

- 1,577

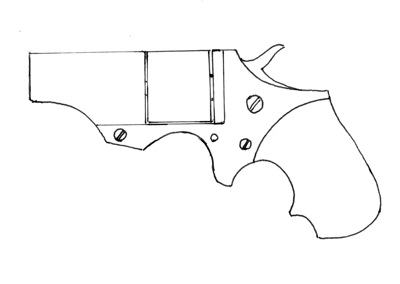

Here's the outside view of my current concept for a home-made .22 revolver. I'd show you the insides but... well, it's messy. As I keep learning from build to build the concept keeps changing.

This is designed so that the mechanism will operate with the side-plate off, which completely exposes the mechanism. That will make it quite a bit easier to fit and fuss with the various bits to get the timing correct.

The mechanism is a variation on the 'tried-and-true' lockwork used in my last two builds- with the addition of a pawl to rotate the cylinder. The side-plate will be relieved to accommodate this. The cylinder is 'locked' at the front by a spring-plunger that engages the cylinder-opening opposite the chamber being fired.

The gun in the picture has a 2" barrel and a short grip, but it could just as easily have a 4" barrel and full-length grip. The frame is 5/8" thick, the Cylinder is 1-1/4 inches in diameter and holds six shots. The gun would load through an open port in the circular breech-plate, which might or might not have a loading-gate.

It might be possible to build this without the lathe or mill- but having those working would make this a hell of a lot easier! It's likely to be some time and who knows how many more modifications before I actually build this thing (or something like it) but I am closing in on a finished design.

This is designed so that the mechanism will operate with the side-plate off, which completely exposes the mechanism. That will make it quite a bit easier to fit and fuss with the various bits to get the timing correct.

The mechanism is a variation on the 'tried-and-true' lockwork used in my last two builds- with the addition of a pawl to rotate the cylinder. The side-plate will be relieved to accommodate this. The cylinder is 'locked' at the front by a spring-plunger that engages the cylinder-opening opposite the chamber being fired.

The gun in the picture has a 2" barrel and a short grip, but it could just as easily have a 4" barrel and full-length grip. The frame is 5/8" thick, the Cylinder is 1-1/4 inches in diameter and holds six shots. The gun would load through an open port in the circular breech-plate, which might or might not have a loading-gate.

It might be possible to build this without the lathe or mill- but having those working would make this a hell of a lot easier! It's likely to be some time and who knows how many more modifications before I actually build this thing (or something like it) but I am closing in on a finished design.