hawg

Member

Same with my Jeager. Stock even has cast-off.

View attachment 1183840

My Hawken has cast off too.

Same with my Jeager. Stock even has cast-off.

View attachment 1183840

They even supply the flint! How can you go wrong with a kit like that?It finally got here. The stories are all true. The fit is very, very close with very little finish work required. The trigger guard is the worst of it.

Wow. That sounds like one fine dang Hawken. That (cast off) sure makes a difference. Do the Kiblers have it?My Hawken has cast off too.

Wow. That sounds like one fine dang Hawken. That (cast off) sure makes a difference. Do the Kiblers have it?

Kibler is very conservative on there wood grading, not sure if I'd get the better wood since all his wood is nice. He keeps improving the kits to which is unlike other kits, you see your butt plate is cnc machined and think some day the triggerguard and all other parts to. Probably the strongest lock made since its made out of solid stock, think the cock and frizzem are still cast. It's almost getting to the point there not kits, it's just a pre made gun you put together lol.I ordered a plain maple stock. I wet it down some to see the figure better. It's definitely not plain. I've got to wait until next month to get new files, stones and sandpaper. I was dreading the day it got here because I just knew it was going to be too much for my limited skills. I'm actually looking forward to getting started.

I hope Dixon's says open, not telling how long they will be since there not doing the gunmakers fair anymore.Moving back to PA in 2024. Will be building two longrifles and one pistol from kits during my retirement. Have friends back east who make these professionally. Also going back to Dixon’s.

They moved the fair a few miles down the road. Loved going there in the early 2000s.I hope Dixon's says open, not telling how long they will be since there not doing the gunmakers fair anymore.

Ya but Dixon's doesn't have any part in it anymore, I haven't been to the new place for the fair yet but hope to go this year if I've got the money. I do a loop stopping at cabelas, sarco then dixons, it's almost 3 hours drive for me.They moved the fair a few miles down the road. Loved going there in the early 2000s.

Yes, the Woodsrunner stock has 3/16" cast-off.That (cast off) sure makes a difference. Do the Kiblers have it?

Yes, the Woodsrunner stock has 3/16" cast-off.

Nice so far! You’ll turn into a first rate wood-butcher in no time! How shiny are you going with the metal?

TIP - Jim recommends the Bahco brand of files for draw filing and even though I thought I had good DF'ing files, I bought one of each (only $10-11 each when I bought them) and they are THE FASTEST cutting files I've ever used!

@hawg - I made this one below, if you need any inspiration or ideas for adornment/finishing. It was his mid-grade wood, of which I too thought punched above it's weight!

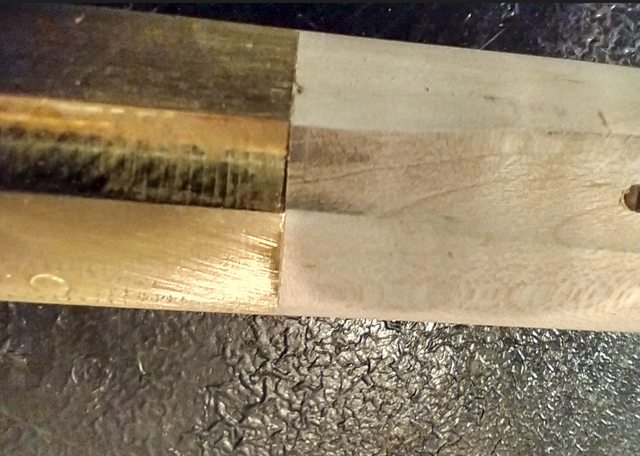

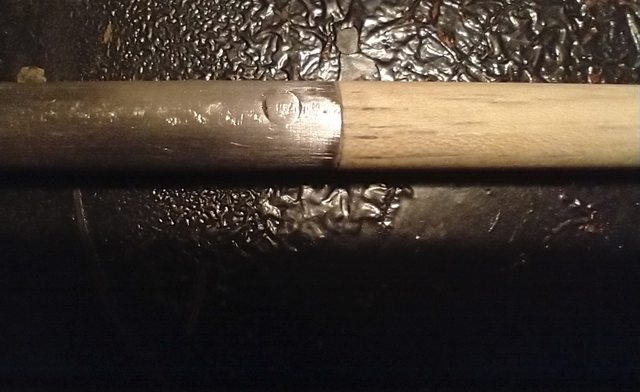

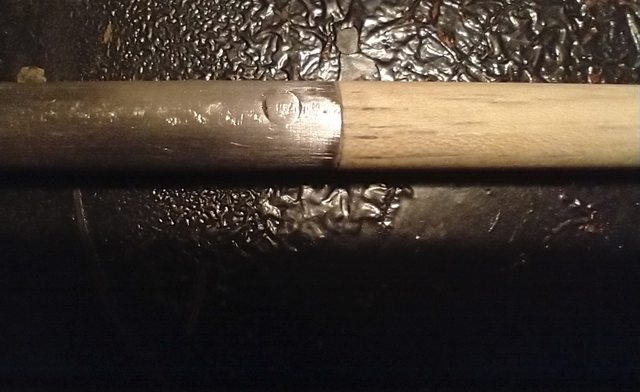

The wood-to-metal fit on the butt plate is fantastic!

I'm surprised the tang stands so proud. Is it really all the way down in its mortise? I'd hate to have to cut so much metal...

You might send a picture to Kibler and see what he thinks. I agree with removing material from the underside, possibly using inletting black as yo go to keep solid contact with the mortise.It's really not that much. The camera makes it look worse than it is. The battery in my calipers is dead so I can't tell how much difference there is but the tang is definitely thicker than the inlet is deep. There's a lot of meat on the tang so I don't see where filing a few thousandths off is going to hurt anything. The screw does pull the tang down into the inlet some without any strain but when it stops it stops solid. I think I'm going to file the bottom until I get past the screw hole so I don't mess up the countersink and then file from the top where the tang is thicker.

It's really not that much. The camera makes it look worse than it is. The battery in my calipers is dead so I can't tell how much difference there is but the tang is definitely thicker than the inlet is deep. There's a lot of meat on the tang so I don't see where filing a few thousandths off is going to hurt anything. The screw does pull the tang down into the inlet some without any strain but when it stops it stops solid. I think I'm going to file the bottom until I get past the screw hole so I don't mess up the countersink and then file from the top where the tang is thicker.