nettlle

Contributing Member

Every now and then I will run across reloading information talking about metric primers. I am trying to figure out if there is any difference between metric and standard primers.

I think what you will find is the “dimensions” are the same but the rounding error in converting from mm->inch and vice-versa creates some variation.I been trying to look up the difference between them and not having any luck.

Tula, S&B, SyA, Wolf, Ginex, and others....................................I've never heard of metric primers.

Where dos it say that these are metric?Tula, S&B, SyA, Wolf, Ginex, and others....................................

Tula, S&B, SyA, Wolf, Ginex, and others....................................

It doesn't say, however they are manufactured in a country that utilizes the metric system of measurement..............Where dos it say that these are metric?

These do not look like berdan primers to me....??I load S&B all the time & the normal boxer primers fit fine. Most others like Tula, Wolf, Ginex, are steel cases & are berdan primed.

No. Each manufacturer is responsible for producing a product which meets the inspection requirements of their market. In converting from metric to inch there is some rounding error which can (and has) result in fitment failure. The problem is easy to solve but some people find it annoying to deal with. I think the problem is with the end user, not the part, but that’s just me. I’m pretty flexible.Are metric primers specific to metric calibers? Are both 9mm Makarov and 9mm primers available?

Where dos it say that these are metric?

No, the difference between Boxer primers and Berdan primers have nothing to do whether they are metricI have heard of boxer & berdan primers but I've never heard of metric primers.

Most ammo coming from metric countries have berdan primers could that be what he is talking about?

Primers come in 4 designations: Small Pistol (SPP), Small Rifle (SRP), Large Pistol (LPP), and Large Rifle (LRP)...they aren't caliber specific. Both cartridges in your question are metric calibers and use SPPAre metric primers specific to metric calibers? Are both 9mm Makarov and 9mm primers available?

Wolf is an importer and doesn't manufacture ammunition. They import ammo with both brass and steel cases, also with both Boxer and Berdan primersWolf, Ginex, are steel cases & are berdan primed.

The 9mm Makarov primers in reloadable brass that I have see are boxer primers.Are metric primers specific to metric calibers? Are both 9mm Makarov and 9mm primers available?

Where dos it say that these are metric?

Every now and then I will run across reloading information talking about metric primers. I am trying to figure out if there is any difference between metric and standard primers.

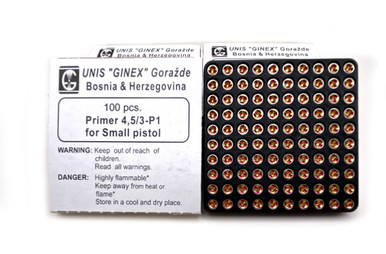

Yes, and I can only get one less Ginex in the tube. 99 compared to a 100 with US primers. Which is annoying as heck.I can confirm a very slight difference in size in Ginex vs CCI military large rifle. When I load the primers into the tubes for the dillon, the ginex stack is taller. not a lot but consistently taller.

oh good. I'm not the only one with that problem. I thought I was crazy. you can get all 100 if you pull the end pickup cap out a bit.Yes, and I can only get one less Ginex in the tube. 99 compared to a 100 with US primers. Which is annoying as heck.

Or switch to the the brass tips...but then you get the "one hangs when dumping in the priming tube", so I use my primer follower to rod the pickup tube through. Then as well, small primers stack up at the gate in auto priming systems like the Mark 7 revo...so you have to watch that. I made a special tool....a straightened paperclip with a tiny hook on the end for reaching in and hooking the hanger, lol.oh good. I'm not the only one with that problem. I thought I was crazy. you can get all 100 if you pull the end pickup cap out a bit.

I think the problem is with the end user, not the part, but that’s just me. I’m pretty flexible.