Hooda Thunkit

Member

I agree, 3 cap screws is essentially a quick-change.So 3 cap screws to change the turret? That's still pretty quick.

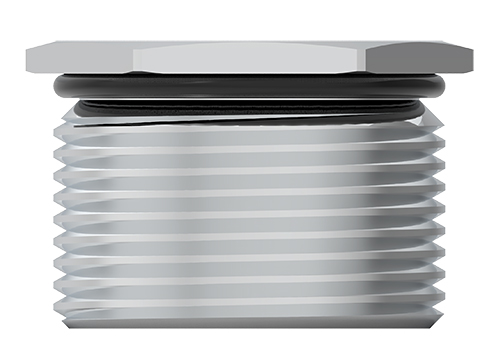

However, one needs the bushings to use the turret. Dies will not screw in the turret unless there is a bushing present. No sense in buying extra turrets, when one needs to also buy the bushings for it.

One may as well just own one turret, and insert the bushing-mounted dies in that single turret.

With the exception of the current 4-hole turret presses, does Lee even make a press that doesn't require those bushings?

As I started earlier, it seems that the entire Lee company now revolves around those bushings, that work only in Lee presses.

Perhaps Lee thinks that those bushings may become a standard, and they can license it to other press makers, much as happened with the case-operated powder measure.

I don't know. It's seems a gamble, to make your press something that is essentially unusable with standard dies unless one buys additional equipment.