Long before Hornady or Dillion offered counters I had made my own. This is the third revision. I've improved greatly on the detection switches and a minor tweak to the circuit so that it won't count when the primer tray is empty.

In between Rev 2 and Rev 3 I reloaded ~10,000 rounds without a counter and it's not a problem, I just like having the counter and lights to let me know how many I've primed and when I don't have a primer in the tray.

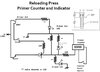

Here's how it works: There is a switch that only makes contact when the press goes all the way to the prime position. It latches a circuit that sends a signal to the counter and activates a green light to let you know you've primed the brass. On the upward movement of the press a Normally Closed magnetic switch resets the latch. This prevents double counting if you double pump the handle for some reason. When the primer tray locks in the backward position it activates another switch which, disables the latching circuit and turns on the red light to let you know there's no primer.

Yes, before you asked, I cut off the brass auto-feed arm. I don't intend to get a feeder and it was just in the way. I will replace the button magnet with a small bar one when I get the chance.

PICTURES ARE BELOW, if you want to skip the technical stuff.

I use an ENM counter module. They're available from the normal electronic suppliers, like Digi-Key. It's a self contained model with an LCD screen. Self powered, good for ~10years. Won't loose count. The latch is a generic power SCR. I added an on-board LED just for fun and trouble shooting. I also have current limiting resistors for the gate and the counter just to be safe. I also put a permanent load resistor, 2k across the SCR, because the counter by itself doesn't draw enough current to keep it latched. The LED will keep it latched but during testing I didn't always have the LED connected. The Primer Out Switch is an SPDT and I use it to lockout the counter when the primers are out. No reason to count the priming motion if there aren't any primers. I did this using a 12v supply but it will work with lower voltages down to the minimum the counter requires. The LEDs are a little "knobby" but they're what I had. Since they're 12Vdc no dropping resistor is required. As you can tell the circuit board is more about connections than electronics.

My next revision I want to use a linear position detector instead of the Prime and Reset switches and to use a PIC so I can program a warning when the press goes more than half-way up but it didn't prime.

In between Rev 2 and Rev 3 I reloaded ~10,000 rounds without a counter and it's not a problem, I just like having the counter and lights to let me know how many I've primed and when I don't have a primer in the tray.

Here's how it works: There is a switch that only makes contact when the press goes all the way to the prime position. It latches a circuit that sends a signal to the counter and activates a green light to let you know you've primed the brass. On the upward movement of the press a Normally Closed magnetic switch resets the latch. This prevents double counting if you double pump the handle for some reason. When the primer tray locks in the backward position it activates another switch which, disables the latching circuit and turns on the red light to let you know there's no primer.

Yes, before you asked, I cut off the brass auto-feed arm. I don't intend to get a feeder and it was just in the way. I will replace the button magnet with a small bar one when I get the chance.

PICTURES ARE BELOW, if you want to skip the technical stuff.

I use an ENM counter module. They're available from the normal electronic suppliers, like Digi-Key. It's a self contained model with an LCD screen. Self powered, good for ~10years. Won't loose count. The latch is a generic power SCR. I added an on-board LED just for fun and trouble shooting. I also have current limiting resistors for the gate and the counter just to be safe. I also put a permanent load resistor, 2k across the SCR, because the counter by itself doesn't draw enough current to keep it latched. The LED will keep it latched but during testing I didn't always have the LED connected. The Primer Out Switch is an SPDT and I use it to lockout the counter when the primers are out. No reason to count the priming motion if there aren't any primers. I did this using a 12v supply but it will work with lower voltages down to the minimum the counter requires. The LEDs are a little "knobby" but they're what I had. Since they're 12Vdc no dropping resistor is required. As you can tell the circuit board is more about connections than electronics.

My next revision I want to use a linear position detector instead of the Prime and Reset switches and to use a PIC so I can program a warning when the press goes more than half-way up but it didn't prime.