ohihunter2014 said:

I rent so limited space so a smaller bench is what I had to go with

... cant bolt to floor or wall so putting another brace along the front to help sturdy.

Then a portable castered bench may be the solution. And when you move, you can roll the bench to your new place.

While I had 6' and 8' benches in the garage to reload for years, when I got tired of reloading standing up in the heat/cold, I built a 2'x3' portable castered bench using kiln dried 2x4s and casters from Harbor Freight moving dolly. There's no need for bracing as the 2x4 frame screwed/nailed together with plywood is very stiff. I resize even thicker walled military .308 cases and the bench won't flex or move even when empty on hard floor.

deck mate screws are very expensive and the worst screws I have ever used. square head bit strips them in and out.

I used regular drywall screws with phillips head and 10d nails (likely the lowest cost fastners). I did pilot drill all the screw/nail holes so as to not split the kiln dried 2x4s.

Since the presses are mounted at the ends, bench can roll through the tightest hallways into doorways and will even fit inside closets for storage. Now I reload in comfort of heating/AC anywhere in the house and out in the patio. The bench height allows me to reload either standing or sitting down and I use a comfy office chair with height adjustment for maximum comfort.

When we moved into our retirement house, I didn't even bother moving the 6'/8' benches and I now use the 2'x3' bench along with the 2'x2' bench for reloading. I like the 2'x3' bench so much that I am currently building another 2'x3' portable castered bench for the Dillon 650 and two C-H "H" type presses.

In addition to pistol calibers, I also reload .223/300BLK/.308. I used to build reloading benches for other reloaders and used OSB as top (for lower cost) but used 2x4s as reinforcement that eliminated bench top flex. For my bench, I used 11 layer hardwood plywood for top finished with 2 coats of polyurethane. Since the C-H single stage is mounted at the end, I can resize even thicker walled military .308 cases with an empty bench and the bench does not move even on hard floor.

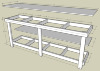

Here's a simple drawing and parts list pdf of the bench -

http://www.thehighroad.org/attachment.php?attachmentid=210769&stc=1&d=1432610198

Pictures showing simple 2x4 reinforcement for thicker plywood top but I have also used two stack deep 2x4s and 2x6 for thinner OSB top.

If you want even a smaller bench for pistol reloading only, I also use 2'x2' portable castered bench. Since OSB was used for top, I got a piece of vinyl at Wally to cover the OSB for easy clean up.