Dane R. Marley

Member

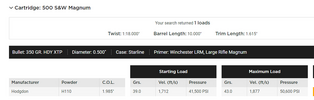

A good buddy of mine has been under the weather. He owns a S&W 500 with 4" barrel, and it is a blast to shoot. He asked me to reload his empty cases and gave me a lot of Hornady 350 gr XTP bullets. He also gave me a pound of H110 and IMR4227. His dies are Lee but it is a 3 die set. I may order a Lee crimp die. I like crimping in a separate stage and not while seating a bullet.

I have LR primers, and the latest Hornady & Lyman Cast Manuals.

I think I will do all of my loading on my MEC Marksman Press. If it works out well I have a T7 or a 750 to move to. He did purchase a Dillon flaring/powder drop tube. Other than lubing the cases for resizing and crimping do you all have any particular tips or thoughts that I need to be aware of?

I may also buy some different powders and some cast bullets from Roger's Better Bullets in King of Prussia.

What are your pets range loads?

I have LR primers, and the latest Hornady & Lyman Cast Manuals.

I think I will do all of my loading on my MEC Marksman Press. If it works out well I have a T7 or a 750 to move to. He did purchase a Dillon flaring/powder drop tube. Other than lubing the cases for resizing and crimping do you all have any particular tips or thoughts that I need to be aware of?

I may also buy some different powders and some cast bullets from Roger's Better Bullets in King of Prussia.

What are your pets range loads?