unclenunzie

Contributing Member

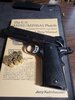

Picked up a Turkish commander style 1911, just to have one for possible carry purposes but mostly because it seemed decently made for a low price (under present conditions). Tisas "Carry" model that specifically lists two things I thought well of: 1) forged frame & slide and barrel/chromed. 2) Uses series 70 type internals. They also put a tag on it says "Hardened Before Machining". Black Ceracote. The slide, frame, and barrel fit looked pretty good, better than expected.

Now, I was certain going into it that every part would be MIM or as cheaply made as possible, and I expected there to be issues. I decided it would be a project gun that when finished would help me learn more about the platform and how to fit parts properly. And if it worked properly and safely I could carry it. But to start, it actually worked fine from the get go. I bought a couple metalform 7 round rounded follower mags, one worked fine, the other mag wasn't made right and I sent it back for replacement (works). A hundred rounds through, no issues, aluminum and brass cased ball.

Things I didn't like: I found the right side safety dug into my (left) thumb uncomfortably. It was also way too thin to reliably hold the plunger, over-travelled past fire, and just plain ugly. The trigger pull was kind of bleh over 5.5 pounds, creep and grit. Decided to do a trigger job on it by buying a sear jig, stones and a hammer squaring file from Brownell's. This worked out just fine and gave me confidence to do more.

So, after destroying a couple of quality MIM thumb safeties learning how to properly fit one, AND how to file metal with proper files, I decided to make the leap to a quality forged thumb safety and tool steel ignition set and extractor. And of course I had to get a quality firing pin stop, and replace the firing pin and all the springs, and well, you get the picture.

What I have left is a bag of what I consider to be junk internal parts and springs, and a pistol that now has all hardened tool steel internals (except ejector) that is 100%. Had I actually planned to completely gut this pistol I probably would have picked a single brand of parts - but wound up going with a mix - All USA made from quality makers:

Slide: Harrison Design Extractor, Firing pin stop, Firing pin. Ed Brown bushing, recoil guide and plug.

Frame: HD disconnector, hammer. EGW sear, mainspring housing. Stock ejector and grip safety. Wilson bulletproof ambi safety, slide stop, plunger tube, plunger assembly, lightweight trigger, mag catch.

Springs: Wolff 23 pound hammer spring, 18 pound recoil spring + extra power FP return spring. Colt Sear spring.

Pins: HD pin set, + Wilson short sear pin.

I fitted each part that needed fitting and made sure every safety and function checked right multiple times. Went through the live fire test procedure to check for hammer follow, sear bounce, doubling, etc, all good.

Things I found along the way:

I had to learn how to file not only on flat surfaces but on curves. Mark the piece, one complete stroke at a time, test fit. Repeat... The right tools matter. You cannot fit a sear without a jig, nor stake a plunger tube without a staking tool. And when properly applied, a Dremel is not a tool of the devil (for chamfering plunger tube frame holes). Tisas did not chamfer the holes originally. I used a cheap punch to tap the original tube off. I think it was glued in.

The slide cut for the safety was cut too deep by Tisas. As a result the safety will ride high locked, bringing the back of the safety stud into contact with the hammer. After fitting to the sear I had to clearance the back of the stud to allow hammer over travel when locked. This took me a while to figure out but once I did I was happy with the result.

I left the original grip safety in place because I am too chicken to tackle fitting one until I learn more. And I want to learn how to cold blue to cover the scratches and worn spots from detail stripping it dozens of times.

Here's a picture after surgery. It's ugly but it works (247 rounds hardball), and will get a new set of

Altamonts once they come in. I really like the Wilson safety. It uses a hammer pin with a screw to hold on the right side safety paddle. The new parts in the gun added several hundred dollars to the price, but for nearly all forged / tool steel parts, I could not buy a name brand 1911 for twice the money, nor learn as much as I did.

"She may not look like much, but she's got it where it counts, kid.” - Han Solo

Now, I was certain going into it that every part would be MIM or as cheaply made as possible, and I expected there to be issues. I decided it would be a project gun that when finished would help me learn more about the platform and how to fit parts properly. And if it worked properly and safely I could carry it. But to start, it actually worked fine from the get go. I bought a couple metalform 7 round rounded follower mags, one worked fine, the other mag wasn't made right and I sent it back for replacement (works). A hundred rounds through, no issues, aluminum and brass cased ball.

Things I didn't like: I found the right side safety dug into my (left) thumb uncomfortably. It was also way too thin to reliably hold the plunger, over-travelled past fire, and just plain ugly. The trigger pull was kind of bleh over 5.5 pounds, creep and grit. Decided to do a trigger job on it by buying a sear jig, stones and a hammer squaring file from Brownell's. This worked out just fine and gave me confidence to do more.

So, after destroying a couple of quality MIM thumb safeties learning how to properly fit one, AND how to file metal with proper files, I decided to make the leap to a quality forged thumb safety and tool steel ignition set and extractor. And of course I had to get a quality firing pin stop, and replace the firing pin and all the springs, and well, you get the picture.

What I have left is a bag of what I consider to be junk internal parts and springs, and a pistol that now has all hardened tool steel internals (except ejector) that is 100%. Had I actually planned to completely gut this pistol I probably would have picked a single brand of parts - but wound up going with a mix - All USA made from quality makers:

Slide: Harrison Design Extractor, Firing pin stop, Firing pin. Ed Brown bushing, recoil guide and plug.

Frame: HD disconnector, hammer. EGW sear, mainspring housing. Stock ejector and grip safety. Wilson bulletproof ambi safety, slide stop, plunger tube, plunger assembly, lightweight trigger, mag catch.

Springs: Wolff 23 pound hammer spring, 18 pound recoil spring + extra power FP return spring. Colt Sear spring.

Pins: HD pin set, + Wilson short sear pin.

I fitted each part that needed fitting and made sure every safety and function checked right multiple times. Went through the live fire test procedure to check for hammer follow, sear bounce, doubling, etc, all good.

Things I found along the way:

I had to learn how to file not only on flat surfaces but on curves. Mark the piece, one complete stroke at a time, test fit. Repeat... The right tools matter. You cannot fit a sear without a jig, nor stake a plunger tube without a staking tool. And when properly applied, a Dremel is not a tool of the devil (for chamfering plunger tube frame holes). Tisas did not chamfer the holes originally. I used a cheap punch to tap the original tube off. I think it was glued in.

The slide cut for the safety was cut too deep by Tisas. As a result the safety will ride high locked, bringing the back of the safety stud into contact with the hammer. After fitting to the sear I had to clearance the back of the stud to allow hammer over travel when locked. This took me a while to figure out but once I did I was happy with the result.

I left the original grip safety in place because I am too chicken to tackle fitting one until I learn more. And I want to learn how to cold blue to cover the scratches and worn spots from detail stripping it dozens of times.

Here's a picture after surgery. It's ugly but it works (247 rounds hardball), and will get a new set of

Altamonts once they come in. I really like the Wilson safety. It uses a hammer pin with a screw to hold on the right side safety paddle. The new parts in the gun added several hundred dollars to the price, but for nearly all forged / tool steel parts, I could not buy a name brand 1911 for twice the money, nor learn as much as I did.

"She may not look like much, but she's got it where it counts, kid.” - Han Solo