Before I drilled out a nipple I would use a small tip on my torch to heat it up. It's amazing how much easier something unscrews after the right amount of heat is applied. Keep the heat away from the cylinder by keeping the flame on the nipple. Then use a nipple wrench on it. It should come right out. No fuss no muss.After soaking in a penetrant, if the nipple will still not come out with the normal wrench, DO NOT twist off the lugs. Instead, proceed as follows.

Get a good quality, hard nipple wrench. If possible, make one out of drill rod and harden it. Remove, or don't put in, the cross piece.

Chuck the nipple wrench in the drill press, tightly. Pad the drill press vise with copper or leather jaws. Put the cylinder, rear end up, in the vise and tighten down, tight!

Adjust the vise and table so that the drill chuck with the wrench is directly over the nipple to be removed, and lock the vise and table.

Bring the nipple wrench down over the nipple, turning the chuck as necessary to line up the wrench with the nipple. If the press has a lock down, press the head down tight and lock it. If not, hold the press head down tightly.

Then grip the drill press chuck as tightly as possible and turn it. It may be necessary to work it back and forth to loosen a stubborn nipple. You can use a short rod the size of the chuck key for additional leverage, but it probably won't be necessary.

If a nipple will not come out with this treatment, it will likely have to be drilled out.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

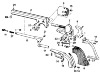

Colt Type Revolver Disassembly

- Thread starter mec

- Start date

- Status

-

Not open for further replies.

Dr. Peter Venkman

Member

Anyone have any pictures to go along with this? I fixed the wedge problem I had with my 1860 Army and I had to do a complete takedown to take care of all of the rust that I found. Now I am having a problem getting it back together. I need help getting the spring, hammer, and trigger in properly.

wacarney29

Member

Hi, I'm not new to cap and ball revolvers...... But its been awhile about 15 years... anyway I bought an 1851 colt in .44, and can't seem to get the wedgr out no matter what. I don't want to scratch the finish up. Any help would be appreciated.

Dr. Peter Venkman

Member

Unscrew the retaining screw and push it out (or using a punch to tap it out) from the thinner side.

scrat

Member

Very nice I posted this a month ago though mec. here is the original posting.

DUP POST

Original post

http://www.thehighroad.org/showthread.php?p=4440990#post4440990

DUP POST

Original post

http://www.thehighroad.org/showthread.php?p=4440990#post4440990

scrat

Member

Yep looks just like the one i posted

DUPE POST AGAIN

DUPE POST AGAIN

old charlie

Member

- Joined

- Apr 28, 2008

- Messages

- 4

The hand spring on my 1851 navy by Uberti broke. I see by Mec's post it will take some fiting. So when it comes in the mail I will have a go at it.

Old Charlie

Old Charlie

Perk

Member

old charlie - Welcome to the Black Powder section of the forum! Someone, here, should have an opinion, or advice, to share before the new spring comes into hand.

If you don’t hear anything, start a new thread. You’ll get their attention and someone’ll be more’n happy to help.

Only advice I can give. Don’t own a ’51 Navy, myself. Good hunting!

Except, also, go to the "?? for Moderators," thread, in this sub-forum. There's a diagram, which might could be helpful, as a start.

If you don’t hear anything, start a new thread. You’ll get their attention and someone’ll be more’n happy to help.

Only advice I can give. Don’t own a ’51 Navy, myself. Good hunting!

Except, also, go to the "?? for Moderators," thread, in this sub-forum. There's a diagram, which might could be helpful, as a start.

scrat

Member

Agreed welcome aboard Old Charlie

dwave

Member

When I fitted the hand to my gun, I used the old one as a template.

tightgroups

Member

What's with the bevel on the hand Mec? Do you understand why it is there..what function it serves?

TG.

TG.

old charlie

Member

- Joined

- Apr 28, 2008

- Messages

- 4

Got my new hand , it was about .003 longer than the old one. I filed maybe .001 off it and put it in the gun. Cock the hammer and it alines perfect and locks the cylinder. But the hammer will not stay at full cock. Where should I be removing medal? On the flat to shorten it further ?

I don’t want to screw this one up. It $18.75 with shipping.

Old Charlie

I don’t want to screw this one up. It $18.75 with shipping.

Old Charlie

old charlie

Member

- Joined

- Apr 28, 2008

- Messages

- 4

Should say will not say at full cock.

Old Charlie

Old Charlie

when you are almost there, it should stay at full cock with the cylinder out. sometimes just a little more off the top is necessary for it to lock up with the cylinder in. Other than that, try to match the sides and end taper, more or less, to your old hand. And no, I don't really know why those bevels are there.

See left:

See left:

old charlie

Member

- Joined

- Apr 28, 2008

- Messages

- 4

Got er done! It took a little more tinkering. Thanks a bunch MEC.

I just love this 51. I have a Walker and a 3rd model dragoon, but the 51 gets most all of the shooting. If it were not storming here now, I would go outside and pop a few caps.

Old Charlie

I just love this 51. I have a Walker and a 3rd model dragoon, but the 51 gets most all of the shooting. If it were not storming here now, I would go outside and pop a few caps.

Old Charlie

tightgroups

Member

Mec,

I figured it out...the bevel...it's a clearance cut so the hand doesn't rub up on the sides too much. That's the only reason I can think of anyway.

TG.

I figured it out...the bevel...it's a clearance cut so the hand doesn't rub up on the sides too much. That's the only reason I can think of anyway.

TG.

thats all I can think of either. I just knew it worked for me and it didn't seem to matter how close I was able to duplicate the original part. My spare (and so far, unnecessary dragoon hands just drop in without any fitting at all and the hands I have fitted to my navy, work perfectly in my 60 army

The 1860 Army has a rebated cylinder - big at the front, smaller at the back, with a step in the center. The rear part, including the ratchet, is exactly the same as the 1851 Navy.

Hammers, triggers, hands, cylinder bolts - and often springs - should interchange between the two models so long as the same manufacturer made both guns.

Hammers, triggers, hands, cylinder bolts - and often springs - should interchange between the two models so long as the same manufacturer made both guns.

Dr. Peter Venkman

Member

My retaining screw simply does not fit with the wedge inserted properly. If I do it backwards I can place it in.

Hey guys Im another noob when it comes to black powder and recently picked up a colt navy replica in 44. I dont know who made it but I assume it was a kit. Ive noticed it was just slapped togeather, without anything being fitted too well. Anyways when I have the revolver level, the cylander will not rotate when the hammer is pulled, but will when the gun is pointed on an upwards angle. I think it has something to do with the bolt, or maybe te cylander isnt sitting back far enough. Any ideas on how I can fix it?

- Status

-

Not open for further replies.

Similar threads

- Replies

- 48

- Views

- 31K

- Replies

- 6

- Views

- 826

- Replies

- 159

- Views

- 10K