....It's time for another DIY project! This one I must say was inspired (one again) by our resident gadget guru @jmorris. I saw his posts using a motorized powder tricker with a balance scale and photo switch a while ago and decided to give it a try.

I started the project using a small stepper motor to drive the trickler, and it worked nicely, but the trickler that I have (Redding) and way I had it controlled was prone to overthrows. No matter what I did, I can not get it to stop dropping multiple kernels at a time. I then came across the "Open Trickler" by Eric Higgins. I don't have a lab grade electronic scale that would replicate that project, but I borrowed his method of building a vibration trickler (similar to the Omega/Dandy tricker).

He documented the trickler build nicely, so I won't replicate that info. The one thing that I found to be tricky was pressing in of the cap screw into the brass pipe...the best way I got the screw into the brass pipe was to chuck the screw into a drill and file down the head a little bit at a time until it can fit into the brass pipe with a little bit of hammer persuasion. Another thing was that simple rubber o-rings did not adequately hold the trickler tube in place to stop it from rotating over time due to the vibration. I 3D printed a couple of small clamps and used it to hold the rubber o-rings against the trickler body. This change also had the benefit to reducing rattling of the trickler tube and allowed a much wider adjustment range of the PWM% to get to the ideal vibration speed. I also 3D printed a thin disk with a 2 degree incline so I can adjust the desired drop tube level.

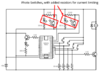

As for the photo interrupter sensor, I ended up using 2x 5/16" Slot PCB Photo switch. One of the switch is about 1.5mm lower than the other. The idea was to go fast until the first switch trips, and then slow down the trickler until the second switch is tripped.

I prototyped it up with an Arduino Uno. What I ended up with really was a copy of the Omega Auto Tricker (discontinued). I added a switche so I can select different settings for stick powder vs ball powder. Added another switch to toggle between auto trickling using the photo switches or just manual trickling with 2 speeds control buttons. There is a small LED that will light up when the second sensor is tripped. That is used to adjust the sensor height. Once everything worked properly, I transferred the project to an Adafruit Pro Trinket to keep the project box small.

It took a little bit of trial and error to fine tune the settings (tuning the vibration motor control voltage via PWM) for both the slow and fast speed settings, but once done, I can start with a dropped charge that is about 0.2 to 0.3 grains short of the target powder weight, once I hit the go button, can have a final trickled charge in about 12 to 15 seconds. Testing indicate that the final trickled charge should be within +/- 1 single kernel of stick power (Varget, H4350, etc.), with vast majority of time being right on the desired weight.

Weighing charges is now quicker, but more importantly, it reduced mental strain of the manual trickling process. This change to the reloading process have made loading precision loads much less of a chore.

I started the project using a small stepper motor to drive the trickler, and it worked nicely, but the trickler that I have (Redding) and way I had it controlled was prone to overthrows. No matter what I did, I can not get it to stop dropping multiple kernels at a time. I then came across the "Open Trickler" by Eric Higgins. I don't have a lab grade electronic scale that would replicate that project, but I borrowed his method of building a vibration trickler (similar to the Omega/Dandy tricker).

He documented the trickler build nicely, so I won't replicate that info. The one thing that I found to be tricky was pressing in of the cap screw into the brass pipe...the best way I got the screw into the brass pipe was to chuck the screw into a drill and file down the head a little bit at a time until it can fit into the brass pipe with a little bit of hammer persuasion. Another thing was that simple rubber o-rings did not adequately hold the trickler tube in place to stop it from rotating over time due to the vibration. I 3D printed a couple of small clamps and used it to hold the rubber o-rings against the trickler body. This change also had the benefit to reducing rattling of the trickler tube and allowed a much wider adjustment range of the PWM% to get to the ideal vibration speed. I also 3D printed a thin disk with a 2 degree incline so I can adjust the desired drop tube level.

As for the photo interrupter sensor, I ended up using 2x 5/16" Slot PCB Photo switch. One of the switch is about 1.5mm lower than the other. The idea was to go fast until the first switch trips, and then slow down the trickler until the second switch is tripped.

I prototyped it up with an Arduino Uno. What I ended up with really was a copy of the Omega Auto Tricker (discontinued). I added a switche so I can select different settings for stick powder vs ball powder. Added another switch to toggle between auto trickling using the photo switches or just manual trickling with 2 speeds control buttons. There is a small LED that will light up when the second sensor is tripped. That is used to adjust the sensor height. Once everything worked properly, I transferred the project to an Adafruit Pro Trinket to keep the project box small.

It took a little bit of trial and error to fine tune the settings (tuning the vibration motor control voltage via PWM) for both the slow and fast speed settings, but once done, I can start with a dropped charge that is about 0.2 to 0.3 grains short of the target powder weight, once I hit the go button, can have a final trickled charge in about 12 to 15 seconds. Testing indicate that the final trickled charge should be within +/- 1 single kernel of stick power (Varget, H4350, etc.), with vast majority of time being right on the desired weight.

Weighing charges is now quicker, but more importantly, it reduced mental strain of the manual trickling process. This change to the reloading process have made loading precision loads much less of a chore.

Last edited: