one stop shopping for answers:

The 5.56mm ball round (M855) runs at 55,000 CUP (copper units of pressure) The 223 Remington was designed to operate at 50,000 CUP.

Differences between the two:

1. Military brass is harder than commercial.

2. Military brass has a heavier wall thickness than commercial.

3. Military brass uses a harder primer cup.*

*this is to deal with pressure

*this is also to prevent slam fires from the inertia of the striker continuing to move forward as the bolt carrier goes into battery

*It's very good idea to use only Remington 7 1/2 small rifle primers in reloads because they have a hard cup that'll tolerate the abuse.

4. Military brass swedges the primer to the brass.**

**this is to help mitigate water from entering the case.

**this is to manage pressure also.

5. Military brass has a smaller powder column (volume) than commercial.

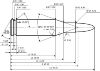

223 Remington cartridge dimensions

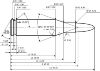

5.56 Nato cartridge dimensions

Where folks have run into trouble:

The M855 ball round uses a 62 (61.7 to be anal about it) grain bullet. The lead and throat angle on M-4's, 16's, and 249's are set as such to permit a bit of freebore (machine guns having the longer of the three). This mitigates pressure spikes and greatly reduces the opportunity for brass to start doing weird things as it allows the bullet a bit of room to get moving before it enters the lands.

If a guy has a firearm set up to shoot 40-55 grain 223 rounds and he starts jamming the heavier (and longer) M855 bullets into the rifle, you run the risk of elevating chamber pressures. This is what leads to blown primers, ruptured cases, etc. Never mind that military barrel dimensions run towards the middle of SAAMI barrel specs for land/groove dimensions where's commercial barrels can be anywhere. (the accurate barrels from marquee makers typically running on the tighter end of things)

WHY?

The 62 grain projectile is longer and it's now obtaining a healthy purchase into the lands of the barrel as soon as its chambered and ready to fire. (Because the chamber is meant for shorter (lighter) bullets) This elevates pressures as it increases the initial resistance (inertia) that must be overcome to get the bullet moving down the barrel. Imagine pushing a car by hand on level pavement and then running over a speed bump. It’s much easier to have a rolling start already right?

This is where pressure is at its peak and where something has to give. Pressure is lazy and takes the path of least resistance so if it can’t vent off by pushing the bullet its going after the next best thing; your primer pockets and your brass. Another reason is the bullet's jacket thickness and the alloy of copper used, all of which are thicker, harder, and heavier than what is typical of commercially available bullets of comparable size.

We can demonstrate this if we go to a military and civilian range. (Wilcox, Edson) where ball ammo is shot all the time. Take a peak at the impact areas. Whole bullets are littered everywhere. Now go to civilian ranges. You see jackets shredded and tore to bits. If you really want to take the time to saw a bullet in half, do so. Compare it to a light skinned J4 jacketed varmint or target bullet. You'll see it right away. This is part of what allows M855 to have fair penetration ability against car doors, etc. Peel the lead out of it, peen it flat and perform a hardness test on it. You’ll see. Then add the steel penetrator in the mix

These are the main reasons why it can be dicey to shoot M855 ball ammo through a bolt gun chambered for the civilian 223. It has nothing to do with cartridge case dimensions being a couple thousandths different here or there or 5,000 more units of copper for pressure. I mean look at the prints. There is essentially no difference. If I took ten pieces of commercially manufactured brass from ten different lots they'd all be different and it’d take an optical comparator equipped with metrology software to even see the variance.

This is the whole point behind fire forming brass and then only resizing the necks so the argument over a dimension less than the thickness of a human hair is a bit silly

SAAMI H/S tolerance put a GO gauge at a "zero" datum and the NO GO at +.006" (two thicknesses of notebook paper basically) So a guy can look at this from two perspectives. One is a "Zero plus six thousandths” tolerance and the other is a +/- .003" tolerance (the dumber of the two choices IMO) Point is if you have a window of 0 to .006" or a window of .003” in either direction you still have plenty of room for a .001" deviation in cartridge dimension.

Makes sense now? Has nothing to do with the cartridge dimensioning. It's the chamber geometry used in the rifle.

I know this because I've built a lot of bolt guns for customers set up to shoot heavy 223 bullets (which require a fast twist barrel) and some (meaning customers) have shot the M855 round just fine because the throat is longer to accommodate the longer bullets. They also shoot well because the M855 bullet requires a faster twist barrel to stabilize. This is because the bullets CG is further forward due to the steel penetrator(creating a design induced instability) than commercial bullets of comparable weight that have solid lead cores. The exceptionally high rotational RPM's of the projectile stabilize it adequately for this type of intended design “flaw”. At 3100fps the bullet is rotating at almost 320,000 RPM. This is why the round has the reputation for being a “tumbler” when it enters soft tissue.

If you find a bolt gun that'll safely fire M855 your still probably going to see poor accuracy because the bullet isn't spinning at nearly enough RPM to stabilize adequately. Any commercially available bolt gun set up with a short throat for light bullets is going to have a 1-11 to 1-14 rate of twist. It may shoot well enough at 100 yards but remember that this cartridge is intended to be able to hit a man size silhouette at 500-600 meters.

Finally. This part applies to AR/M-4/M-16 type rifles. There are only two or three places in the US that manufacture forged receiver blanks. If you walk into a manufacturing plant there is no dividing line between Gov sales and civilian. My point is the rifle I carry in Iraq as a security contractor, Marine, whatever is no different than the one you cab buy in terms of material quality/strength/durability. Mil spec is Mil spec. So long as you use Mil spec parts it does not matter. A bolt gun is no different. If a Rem 700 will take a 338 Lapua Magnum (62,000CUP) it'll shoot a 5.56mm Nato. So have no fear, your not going to blow the receiver up.

This same problem would potentially exist in any cartridge specifically throated for a light bullet and then loaded with a heavier at the optimal seating depth.

I apologize for the long winded dissertation and hope that this long debated subject is finally put to rest. If you have any additional questions or doubts feel free to PM me or call Pacific Tool and Gauge and ask for David Kiff.

Cheers and all the best,

Chad J. Dixon

Gunmaker