I got my new Hornady LNL AP press some days ago. I had to fix some smaller issues and it now seem to work fine when reloading 270 win.

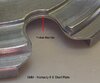

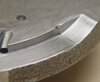

But I do have major problem with reloading .338 win.mag. The press won't eject the finished cartridge because it get stucked between the ejector nub on the sub plate and the shell plate. The spring slips nicely underneat the shell bottom but the nub kinda cuts into the shell. It seems like the nub is too short to guide the cartridge out.

Anyone else who had the same problem?

But I do have major problem with reloading .338 win.mag. The press won't eject the finished cartridge because it get stucked between the ejector nub on the sub plate and the shell plate. The spring slips nicely underneat the shell bottom but the nub kinda cuts into the shell. It seems like the nub is too short to guide the cartridge out.

Anyone else who had the same problem?