In this earlier thread Wilburt discussed a problem with his EZ-Ject spring tipping (Canting) the case going up to station 5.

He figured that if Hornady had machined the sub plate to let the spring drop earlier it would solve the problem.

I posted a pic in that thread which clearly showed the earlier non EZ-Ject LNL sub plate did indeed let the spring drop down sooner, getting under the case, and it did not have the problem that Wilburts newer EZ-Ject sub plate did.

I ordered a EZ-Ject Upgrade (Sub Plate Assembly) and UPS dropped it off today. I immediately started comparing the old sub plate and the new one. Very obvious differences. (Shown in Pics)

I took it out to the shed and after eyeballing it vs the old one, making a couple of observations, setting a shell plate on it to get some measurements, I set out to make a couple of modifications.

First I cut off the part for the case loader. I will never use it and it just gets in the way.

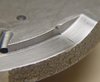

Then I set out to remove some metal from the sub plate to let the spring drop down earlier. I used a Dremel with a course wheel to take off 90% of the metal, a fine wheel to get the next 9%, and 400 grit sandpaper to finish it up.

I think I got it in the right spot, far enough right to let the spring under the case when going up to station 5, but not so far right so it still keeps the spring up over the rim of the case when coming down from station 4.

EZ-Ject Sub Plate

Older Non EZ-Ject Sub Plate

EZ-Ject spring cut out close up

Older Non EZ-Ject spring cut out close up

He figured that if Hornady had machined the sub plate to let the spring drop earlier it would solve the problem.

I posted a pic in that thread which clearly showed the earlier non EZ-Ject LNL sub plate did indeed let the spring drop down sooner, getting under the case, and it did not have the problem that Wilburts newer EZ-Ject sub plate did.

I ordered a EZ-Ject Upgrade (Sub Plate Assembly) and UPS dropped it off today. I immediately started comparing the old sub plate and the new one. Very obvious differences. (Shown in Pics)

I took it out to the shed and after eyeballing it vs the old one, making a couple of observations, setting a shell plate on it to get some measurements, I set out to make a couple of modifications.

First I cut off the part for the case loader. I will never use it and it just gets in the way.

Then I set out to remove some metal from the sub plate to let the spring drop down earlier. I used a Dremel with a course wheel to take off 90% of the metal, a fine wheel to get the next 9%, and 400 grit sandpaper to finish it up.

I think I got it in the right spot, far enough right to let the spring under the case when going up to station 5, but not so far right so it still keeps the spring up over the rim of the case when coming down from station 4.

EZ-Ject Sub Plate

Older Non EZ-Ject Sub Plate

EZ-Ject spring cut out close up

Older Non EZ-Ject spring cut out close up

Last edited: