Having played with Feed and Seating in one station using RCBS's feeder and window seater, and finding it works really well, I've come to the point where I think RCBS and/or Lee is missing a big opportunity.

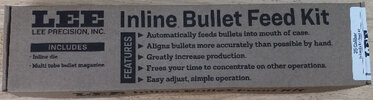

Since they have their new inline bullet feeders in both rifle and pistol, they ought to start making

both rifle and pistol SEATERS with bullet drop-in windows. NOBODY makes such seaters for pistol, they'd have such, all to themselves, and the existing brands rifle seaters with windows are expensive.

What I see in such a move, is giving everyone with plain Jane 5 station presses the effect of have 6 stations, or six pack owners, 7 stations, or ProChucker 7 owners 8 stations! now ....

IF one of them were to make a coupler for sale to use them both in one station. My coupler design works, but someone may come up with a better idea, or they are welcome to mine....I won't be patenting it.

It's almost like Lee designed their six-pack sub-plate for just such a thing....it made it almost too easy!

I used a 9mm shell plate (because it was on there) and .223 wobbles because of it....but it stilll works good enough for testing. My hand in the video was to close one of the shell plate "gates" that I forgot to swivel up to the shell plate. I much prefer RCBS's springs to do that.

The following shorter video shows how Lee's sub shellplate, with it's ledge and bolt holes is perfect to support the part that pushes the feeder from the bottom releasing each bullet....almost as if they planned it for that option.

This allows me to use an "M" expander (which RCBS already has, and Lee is developing) on the SixPack.

1: size; 2: prime and "M" expand; 3: Charge; 4: Powder cop; 5: FeedANDSeat; 6: Taper Crimp.....for rifle. For pistol with PTX's you can save another station for pistol....if they'd just make a windowed Seater.

You can ignore the Red printed part.....that's my home-made LED lighting. Does not effect the feeder.